Method for quickly preparing high-purity chlorophyll and chlorophyll degradation products

A technology of chlorophyll degradation and chlorophyll, applied in the interdisciplinary field of chemistry and enzymology, can solve the problems of high experimental cost, large amount of standard products, long delivery period, etc., and achieve the effects of wide application prospects, efficient and rapid preparation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

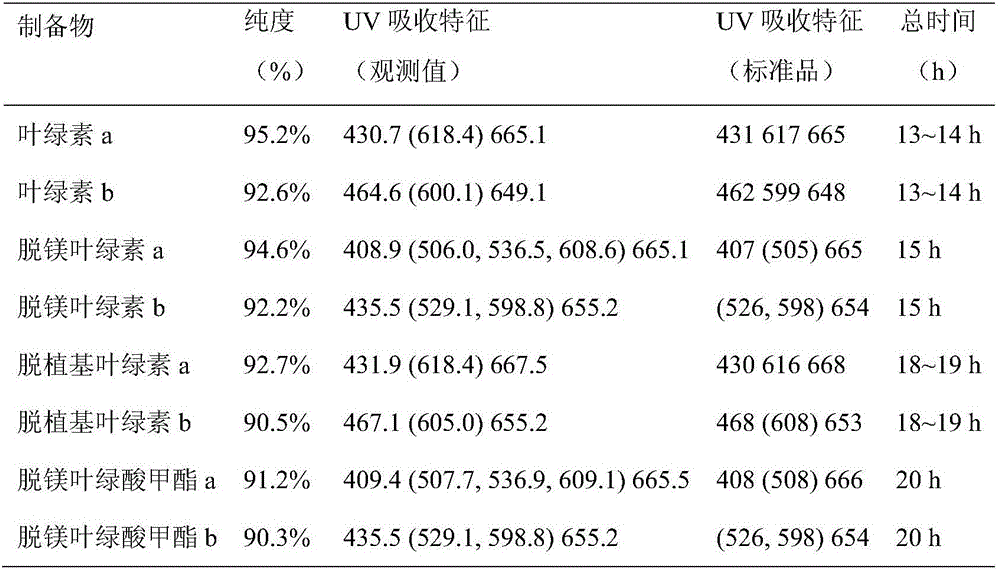

Examples

Embodiment 1

[0030] Purification and preparation of chlorophyll a and chlorophyll b

[0031] (1) Material preparation: pick the fresh sweet potato leaves purchased in the market, remove the old leaves and yellow leaves and remove the petioles, wash and dry in the shade for later use. Wash the fresh Wenzhou tangerines purchased in the market (color difference index CI is -2.0~0.0) with clear water, dry them, and set aside;

[0032] (2) Extraction of total chlorophyll (the following steps are carried out under dark conditions):

[0033] a. Weigh 100 g of sweet potato leaves washed and dried in (1), freeze with liquid nitrogen, and grind into fine powder in a mortar or sample breaker (IKA, Germany);

[0034] b. Pour the sample powder into a 500mL centrifuge bottle (Beckman), add 200mL extract solution (N,N-dimethylformamide, containing 0.1% magnesium carbonate, w / v) and mix well. Ultrasonic cleaner 100% power (100W), ice bath ultrasonic 20min, during which the sample was mixed up and down s...

Embodiment 2

[0040] Preparation of degradation products of chlorophyll a and chlorophyll b

[0041] (1) Preparation of pheophytin a and pheophytin b (pheophytin a and pheophytin b)

[0042] (a) Preparation of pheophytin a (pheophytin a): Weigh 2 mg of chlorophyll a obtained by separating and drying in step (3) of Example 1, and dissolve it in a 10 mL centrifuge tube with 4 mL of anhydrous ether to prepare 500 μg / mL. Add 13% hydrochloric acid drop by drop for acidification, fully shake each drop of hydrochloric acid until the solution turns black and stop immediately. Add 4mL double distilled water to the centrifuge tube, shake for 10 seconds, let stand to separate layers, and absorb the lower aqueous phase. Continue to add 4mL of double distilled water, oscillate and stand for stratification, absorb the lower water phase, repeat this step several times, and stop adding double distilled water when the pH of the lower water phase is measured with pH test paper at 6.8-7.2. Centrifuge at 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com