Method for removing aldehydes in epoxypropane reaction mixture

A technology of reaction mixture and propylene oxide, applied in the direction of organic chemistry, can solve the problems of increasing safety risks and management costs, increasing investment costs, increasing investment, etc., to reduce one-time investment, small one-time investment, and increase safety risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

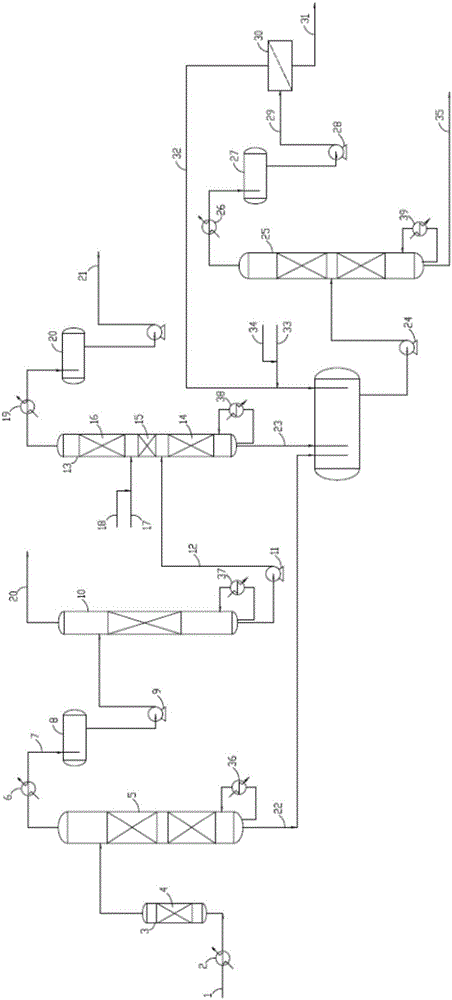

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

[0017] The invention provides a method for removing aldehydes in a propylene oxide reaction mixture. The propylene oxide reaction mixture is passed through the dealdehyde resin tank under a certain temperature and pressure for primary dealdehydeization to reduce the aldehyde content to ensure the purity of the propylene oxide product, and then remove water and unreacted propylene in sequence, containing propylene oxide The material with methanol enters the propylene oxide refining tower, and the propylene oxide refining tower is divided into a formaldehyde removal resin packing section, a water extraction packing section and a distillation section from bottom to top. Extraction, while removing residual aldehydes in the propylene oxide product. The separated aqueous solution containing methanol, propylene glycol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com