Shaftless screw conveyor

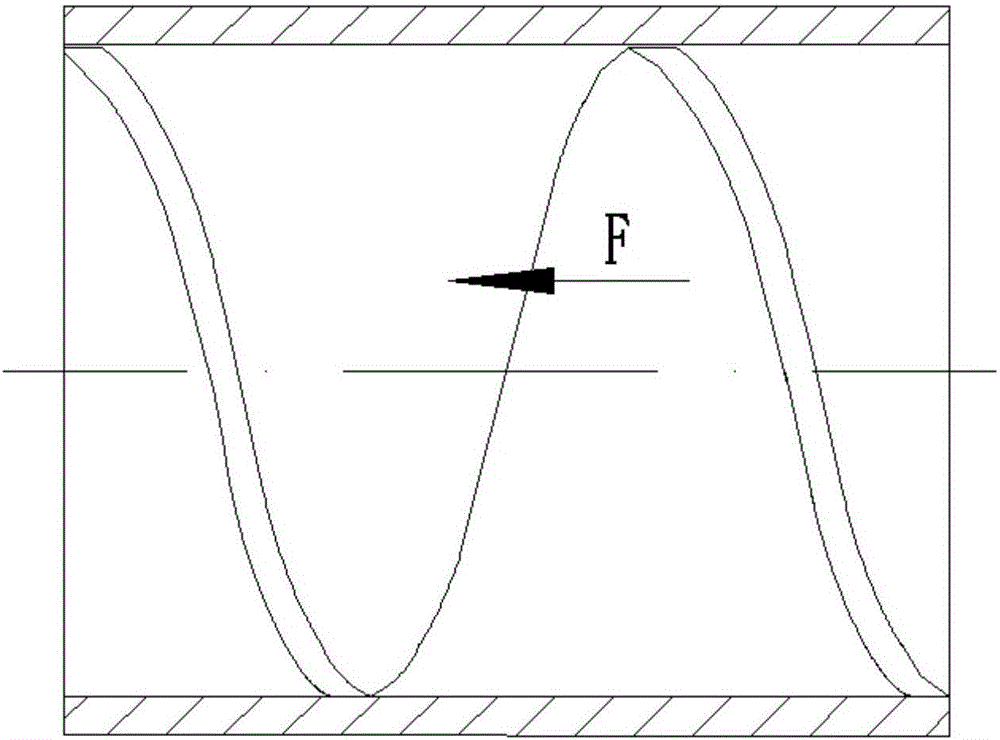

A shaftless screw conveying and conveying cylinder technology, which is applied in the field of conveying, can solve the problems of small conveying volume, blockage of small particle materials, blade wear, etc., and achieve the effects of reducing wear and corrosion, optimizing service life and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

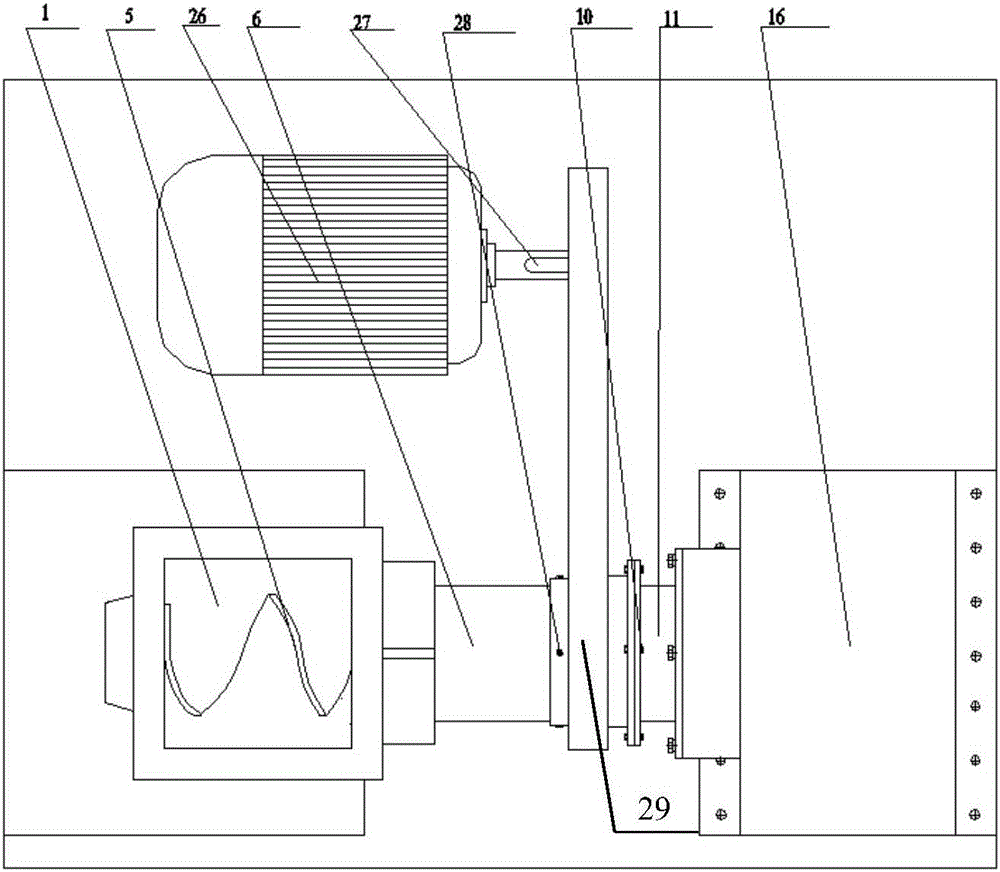

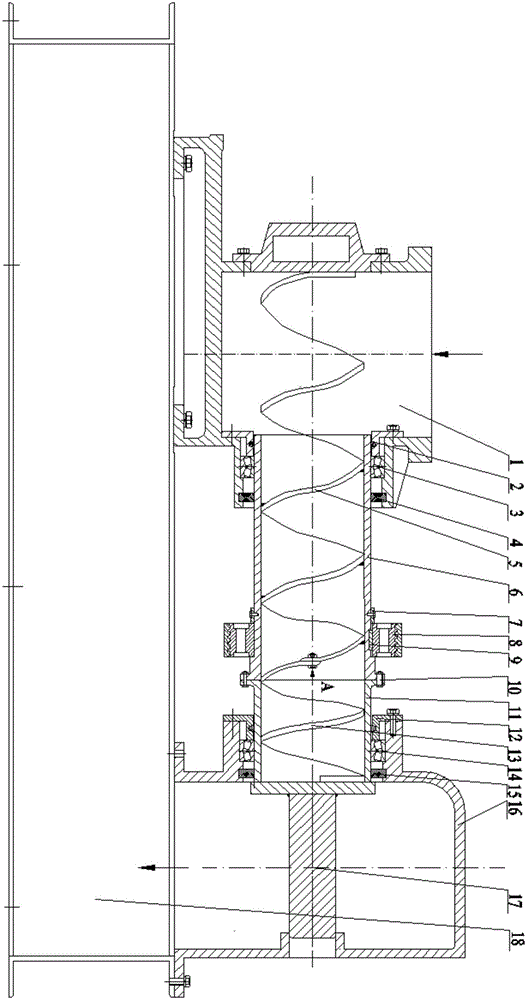

[0024] Such as figure 2 As shown, a shaftless screw conveyor includes a motor 26, a first cylinder conveying cylinder 6, a second cylinder conveying cylinder 11, a first helical blade 5, a second helical blade 13, a feed bin 1, a blanking Case 16, mixing case 18. The output shaft of the motor 26 is connected with the input pulley 29 through the key 9, and the input pulley 29 is connected with the output pulley 8 through the V-belt, and the output pulley 8 is connected with the first cylinder conveying cylinder 6 through the key 27. The output pulley 8 is axially fixed on the first cylindrical conveying barrel 6 through the shaft shoulder and the bushing 7 , wherein the bushing 7 is fixed on the first cylindrical conveying barrel 6 by screws 28 . Using a V-belt as a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com