Full-automatic tapping unit

A multi-head tapping and fully automatic technology, applied in the direction of thread cutting machine, metal processing equipment, thread cutting device, etc., can solve the problems of increased labor cost, unfavorable processing of workpieces to be processed, low production efficiency, etc., and achieves simple structure and advanced technology. Good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

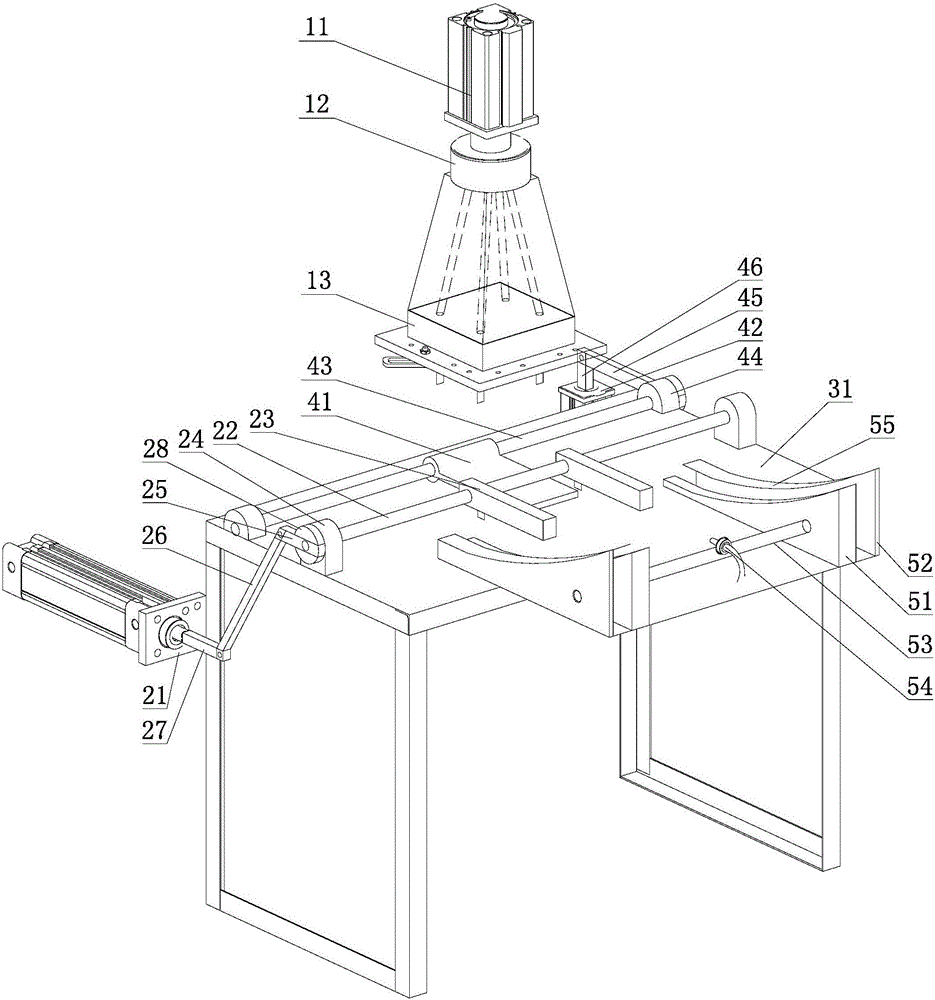

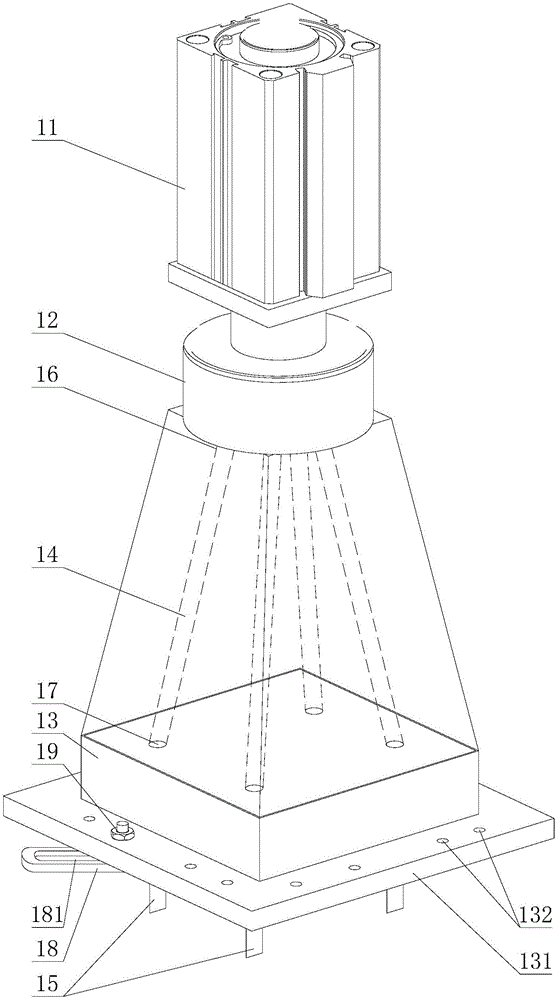

[0018] like figure 1 As shown, the fully automatic multi-head tapping machine includes a head assembly, a clamp, a support plate device and a guide rail device. The head assembly includes a motor 11, a gear transmission, an upper frame 12, a lower frame 13, 4 A transmission rod 14 and 4 taps 15, the motor is fixed on the upper frame, the gear transmission is located in the upper frame, the gear transmission is driven by the motor, the gear The transmission device includes 4 driven wheels, the gear shaft of the driven wheel is connected with the upper end of the transmission rod through the first coupling 16, and the lower end of the transmission rod is connected with the tap through the second coupling 17, The tap is fixed on the lower machine base through a positioning device.

[0019] The positioning device includes a positioning bar 18 and a positioning bolt 19. The tap is passed through one end of the positioning bar. A hole 181, the positioning bolt can pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com