a pd 2 ptag nanocrystal and its preparation method and application

A nanocrystalline and crystalline phase technology, applied in the nano field, achieves the effects of efficient catalysis, low reaction temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] At room temperature, weigh 0.5 mmol Pd(NO 3 ) 2 . 2H 2 O and 0.25 mmol K 2 PtCl 6 Dissolve in 6 mL of OLA and 10 mL of LODE, and add all the materials together into a dry three-neck round bottom flask with a capacity of 250 mL. Transfer the three-necked round-bottom flask to a sand bath, raise the temperature to 250 °C for 10 min at a rate of 7 °C / min under programmed temperature control, and then add AgNO 3 solution (0.25 mmol AgNO 3 dissolved in 3 mL of OLA and 5 mL of ODE), and this incubation was continued for 20 min until the end of the reaction. After the reactor was naturally cooled to room temperature, an appropriate amount of ethanol was added to disperse, and the solid was separated by centrifugation. The solid was washed to obtain a black product, which was used for analysis and characterization after vacuum drying overnight in a vacuum oven.

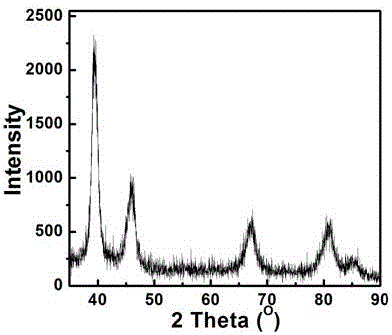

[0031] Using EDS, XRD, TEM and STEM, mapping and line scan test to analyze the product respectively, the res...

Embodiment 2

[0035]In the three-electrode system, the electrochemical properties of the samples were tested by cyclic voltammetry and polarization curve method. The specific process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com