Suspension type filter

A kind of filter and suspension technology, which is applied in the direction of membrane filter, filter separation, mobile filter element filter, etc., can solve the problems of heavy filter work load, rust, and reduced work efficiency, so as to avoid work failure and improve Durability and low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

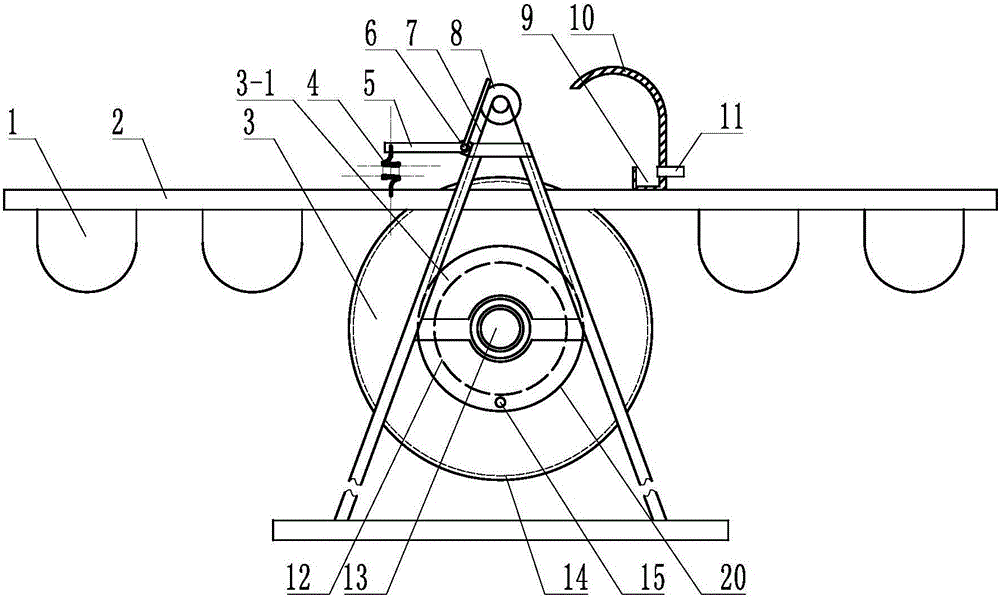

[0043] Embodiment 1: refer to figure 1, is a structural schematic diagram of Embodiment 1 of the present invention, comprising a fixed frame (2), characterized in that: the fixed frame (2) is at least provided with a drive mechanism (8) and a filtering device, and the filtering device includes a filter screen B (14 ) and at least two end plates, the filter screen B (14) forms a cylindrical cylinder, the end plates are located at both ends of the cylindrical cylinder, and the end plate and the filter screen B (14) form a filter cavity, at least An end plate is provided with a water outlet (13), so that the water to be filtered enters the filter cavity through the filter screen B (14) from the outside, and then is discharged from the water outlet (13); the end plate is provided with a central axis, and the filter screen B (14) and the filter cavity formed by the end plate are fixed on the fixed frame (2) by the central axis, and can rotate around the central axis, and the above-...

Embodiment 2

[0045] Embodiment 2: Compared with Embodiment 1, the difference of this embodiment is that: the fixed frame (2) is also provided with a water collection tank (10), and the water collection tank (10) is located at the rear of the filter device, collecting The top of the water tank (10) is arc-shaped, and the bottom is provided with an inverted "Π"-shaped miscellaneous tank (9). ) to discharge impurities in the direction of water flow.

[0046] In actual use: in the flowing water, there will be impurities close to the frame. By setting the water collection tank (10), not only the water intake of the filter device can be increased, but also the impurities in the water can be collected in the miscellaneous collection tank at the lower part of the water collection tank (10) (9), finally discharged by the miscellaneous discharge port (11), which does not affect the work of the whole system and prevents impurities in the water from winding on the float (1) or the fixed frame (2).

Embodiment 3

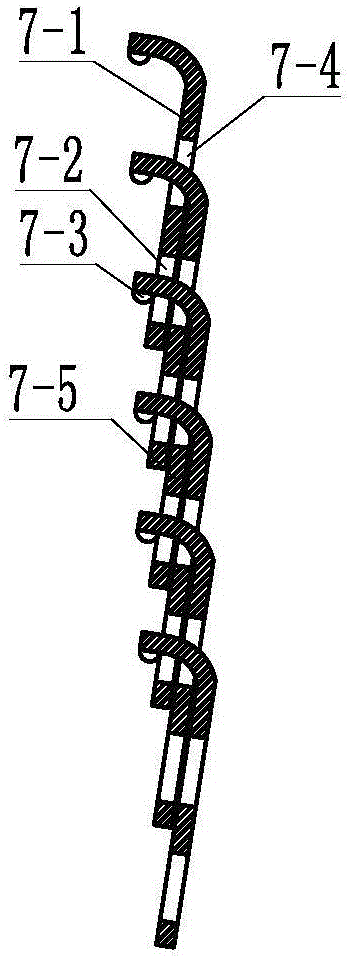

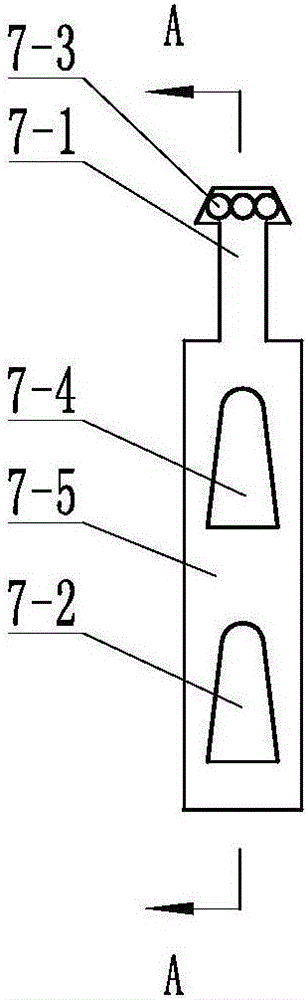

[0047] Embodiment 3: refer to Figure 2-5 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with any embodiment of Embodiments 1 to 2, the difference of this embodiment is that the driving mechanism (8) and the filter device are driven by a transmission chain (7), The transmission chain (7) is composed of a plurality of monomers which are plugged end to end, and the monomers include a chuck (7-1) and a body (7-5), and the body (7-5) is provided with a fixing hole A ( 7-2) and fixing hole B (7-4), the above chuck (7-1) can pass through fixing hole A (7-2) and / or fixing hole B (7-4), and with fixing hole A (7-2) and / or fixing hole B engage with each other.

[0048] In actual use: pass the chuck (7-1) through the fixing hole A (7-2) or the fixing hole B (7-4), and connect at the end to form a strip-like chain.

[0049] Or, pass the chuck through the close fixing hole B (7-4), and then pass through the second fixing hole A (7-2), and so on, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com