Three-stage transconductance amplifier

A technology of transconductance amplifier and input structure, applied in amplifiers, differential amplifiers, amplifiers with semiconductor devices/discharge tubes, etc., can solve the problems of increased layout area, low voltage slew rate of transconductance amplifiers, and reduced dominant pole frequency , to achieve the effect of increasing the unity gain bandwidth, maximizing, and increasing the voltage slew rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0027] In order to describe the above problems in more detail, first analyze the working principle of the two three-stage transconductance amplifiers and the advantages and disadvantages of frequency compensation technology.

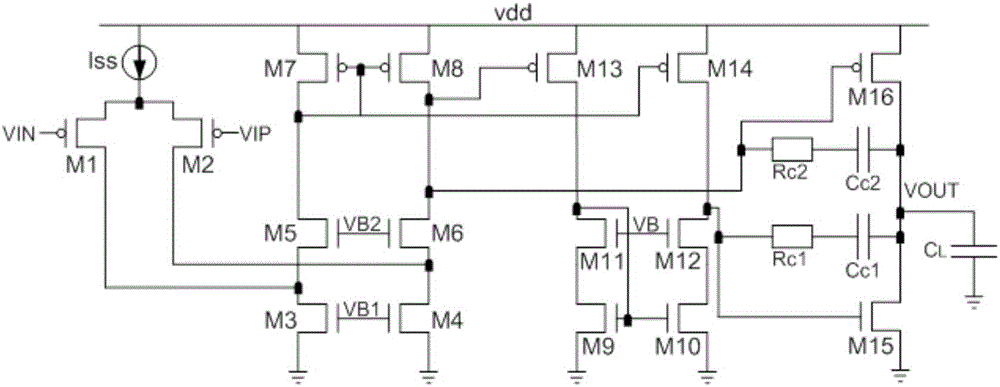

[0028] Such as figure 1 A schematic diagram of a traditional three-stage transconductance amplifier RC compensation technology (referred to as the structure [1]) is given. The two compensation networks are respectively composed of compensation resistor Rc1 / compensation capacitor Cc1 and compensation resistor Rc2 / compensation capacitor Cc2 in series. One end of the compensation resistor Rc1 is connected to the compensation capacitor Cc1, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com