A micro power generation device

A power generation device and micro technology, applied in electromechanical devices, electrical components, etc., can solve the problems of energy density not meeting the requirements, complex process, etc., to achieve the effect of simple structure, reduced module volume, and improved stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

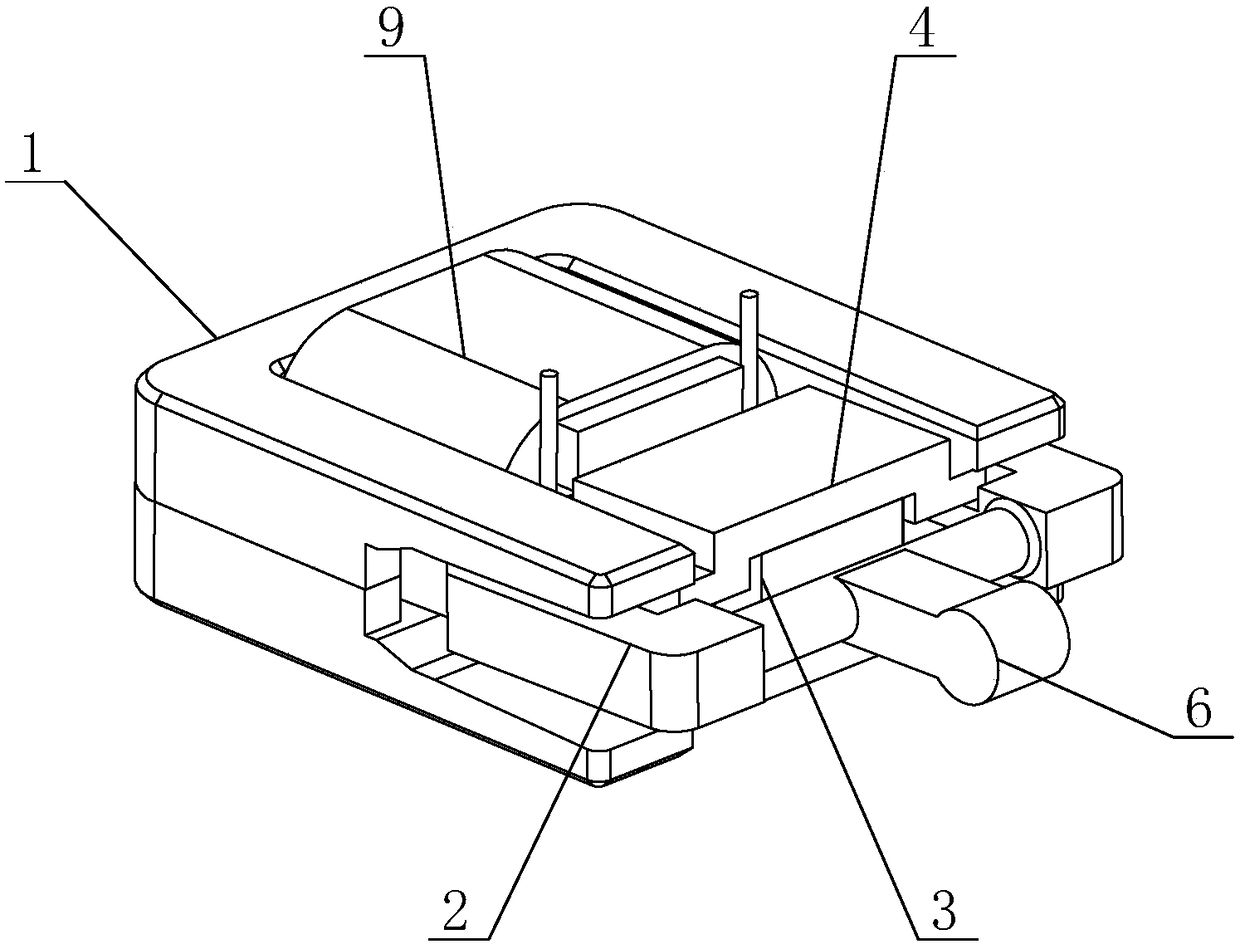

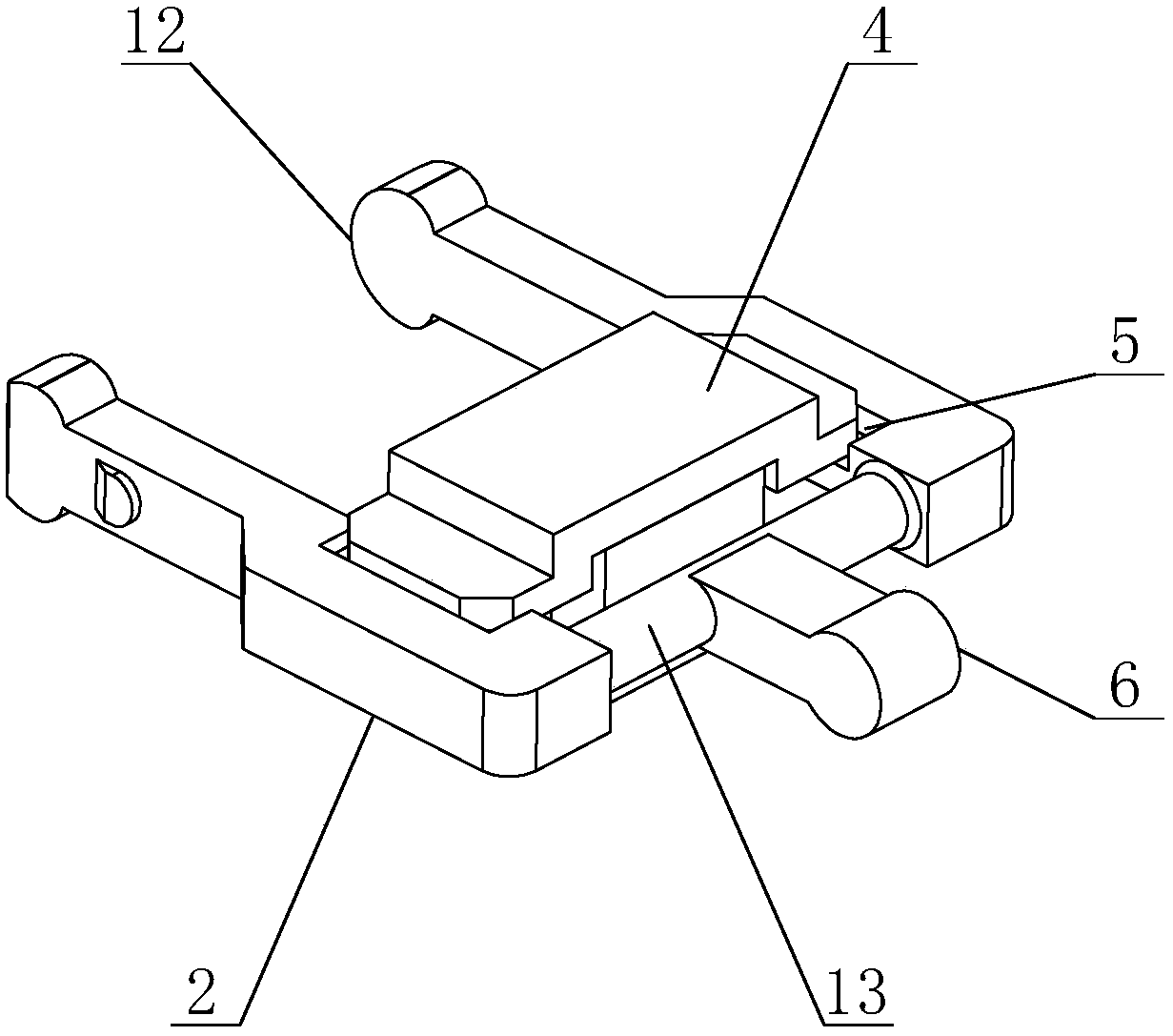

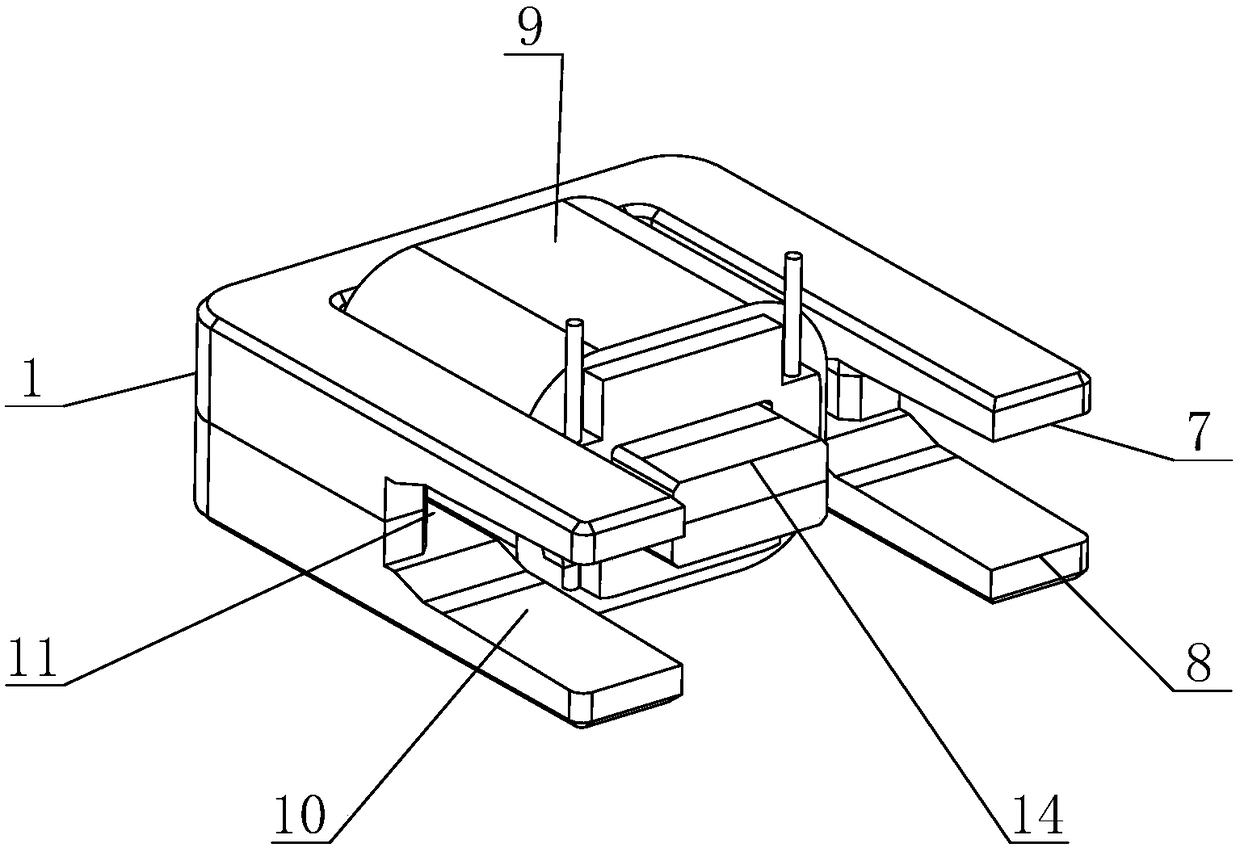

[0032]A miniature power generation device includes moving parts and an iron core 1 matched with the moving parts. The moving parts include a magnet frame 2, a magnet 3 and a magnetically conductive sheet 4. Mounting grooves 5 are arranged on both sides of the magnet frame 2, and a magnetically conductive sheet 4 is installed in the mounting groove 5. The magnetically conductive sheet includes an upper magnetically conductive sheet. A sheet 41 and a lower magnetically conductive sheet 42, the magnet 3 is located between the two magnetically conductive sheets 4. One end of the magnet frame 2 is provided with an operating head 6, and one end of the magnet frame 2 near the operating head 6 is provided with an elastic deformation zone 13, which can provide torsional elastic deformation in a small and micro range, play an elastic buffering role, and reduce the impact of the toggling speed. The influence of the moving speed of the moving parts makes the overall performance of the mic...

Embodiment 2

[0034] A miniature power generation device includes moving parts and an iron core 1 matched with the moving parts. The moving parts include a magnet frame 2, a magnet 3 and a magnetically conductive sheet 4. Mounting grooves 5 are arranged on both sides of the magnet frame 2, and a magnetically conductive sheet 4 is installed in the mounting groove 5. The magnetically conductive sheet includes an upper magnetically conductive sheet. A sheet 41 and a lower magnetically conductive sheet 42, the magnet 3 is located between the two magnetically conductive sheets 4. One end of the magnet frame 2 is provided with an operating head 6, and one end of the magnet frame 2 near the operating head 6 is provided with an elastic deformation zone 13, which can provide torsional elastic deformation in a small and micro range, play an elastic buffering role, and reduce the impact of the toggling speed. The influence of the moving speed of the moving parts makes the overall performance of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com