Three-phase energy saving transformer with unlaminated core and zero-clearance magnetic circuit

An energy-saving transformer, non-laminated technology, applied in the field of transformers, can solve the problems of increasing transformer no-load loss, low efficiency of transformer working hours, large transformer no-load loss, etc., to reduce reluctance, reduce manufacturing difficulty and cost of working hours, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

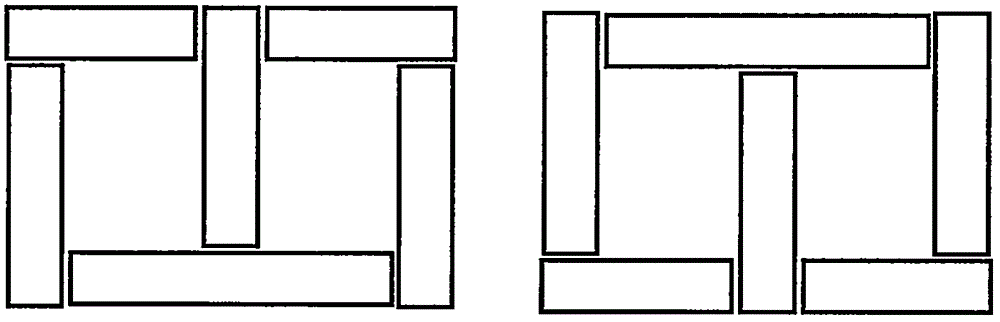

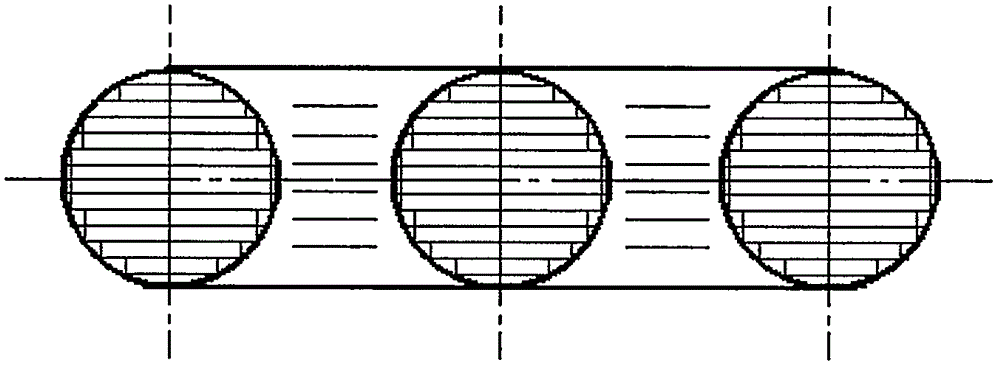

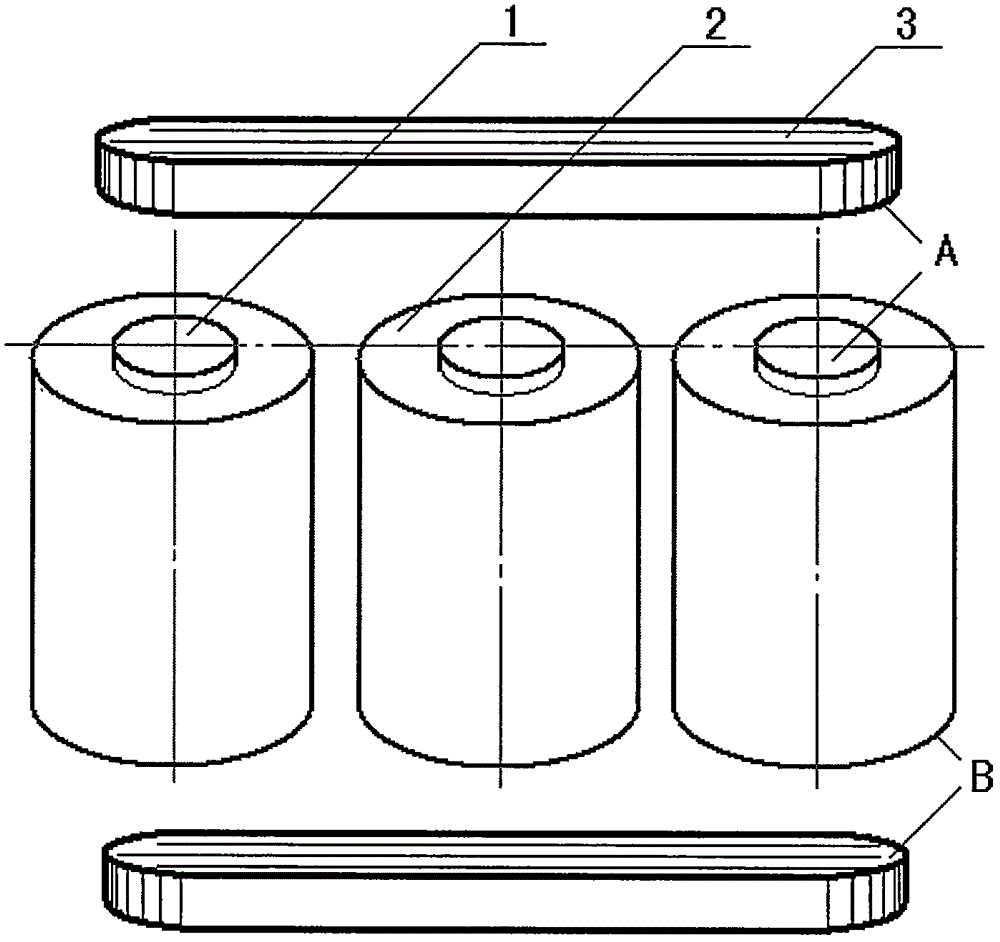

[0021] The definition of the magnetic circuit structure of the transformer of the present invention is different from that of the traditional transformer and must be defined separately.

[0022] In the present invention:

[0023] Core (1): Only refers to the magnetic device in the winding.

[0024] Winding (2): Refers to the electrical chain of the transformer, which is the device through which the alternating current of the transformer enters and flows out.

[0025] Iron yoke (3): Refers to the magnetic device in the transformer that connects the magnetic currents in the iron core to each other and completes the circuit.

[0026] Magnetic circuit: Refers to the flux linkage of the transformer, which is the general term for the entire magnet of the transformer, including the iron core and iron yoke.

[0027] In a traditional transformer:

[0028] Core: also called core, core column, core column, which is equivalent to the iron core (1) of the present invention.

[0029] Yo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com