Flow metering system for oilfield production fluid

A technology of flow measurement and produced liquid, which is applied in the direction of volume measurement, liquid/fluid solid measurement, and measurement capacity, etc. It can solve the problems of large equipment maintenance, affecting measurement accuracy, and failure of medium compensation, etc., and achieves high liquid level measurement accuracy , Improve measurement accuracy and ensure safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

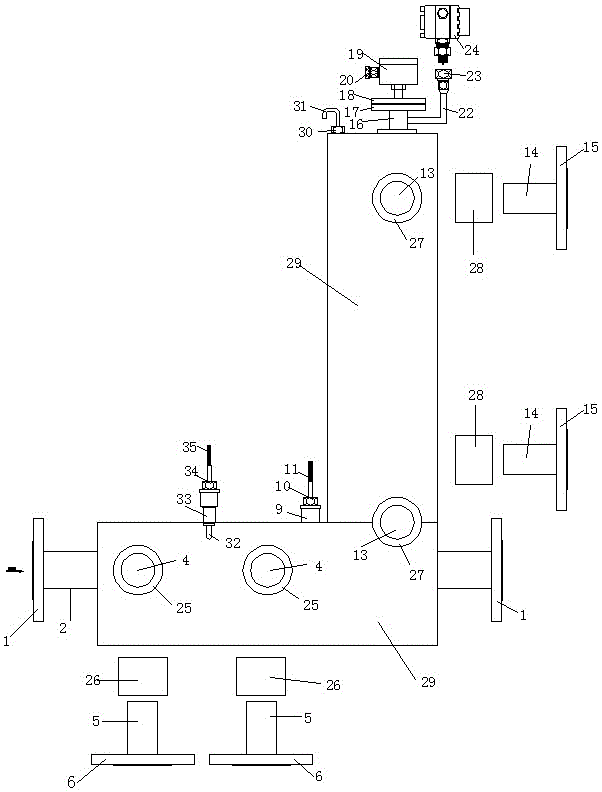

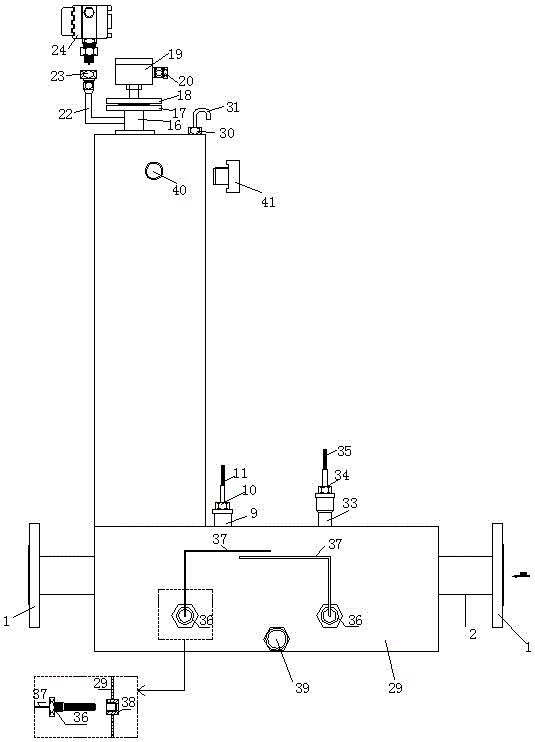

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] Such as Figure 1-Figure 6 As shown, the oilfield production fluid flow measurement system is composed of a flow measurement mechanism, a compensation mechanism and a data calculation mechanism connected to each other as a whole; Conveyor 50, a connection flange 1 is welded at both ends of the horizontal pipe 2, a wedge-shaped throttling piece 3 is welded inside the horizontal pipe 2, and a flow pressure hole 4 is respectively opened on both sides of the wedge-shaped throttling piece 3 on the horizontal pipe 2 , Weld the flow pressure connection pipe 5 on the flow pressure hole 4, weld the flow pressure connection flange 6 on the flow pressure connection pipe 5, and weld the flow pressure connection flange 6 through the flow transmitter to take the pressure flange fixing screw 53 is connected to the pressure-taking flange 48 of the flow transmitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com