Material surface strain fiber grating reverse differential detection sensing device

A technology of fiber grating and sensor devices, which is applied in the field of material surface strain fiber grating reverse differential detection sensor devices, which can solve the problems of low precision and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

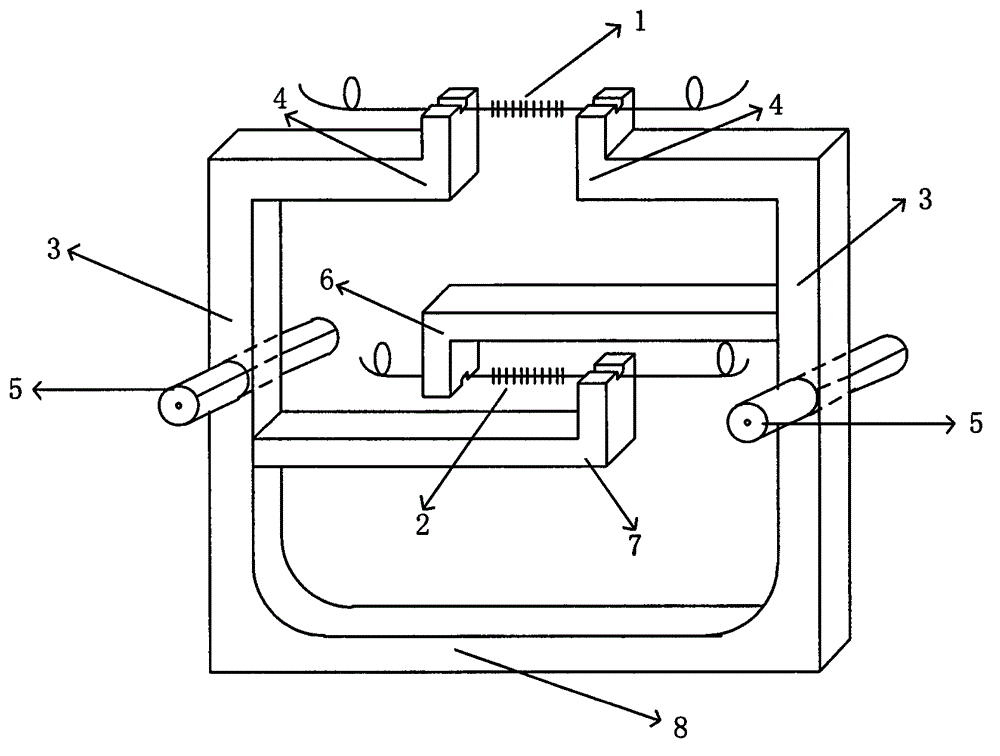

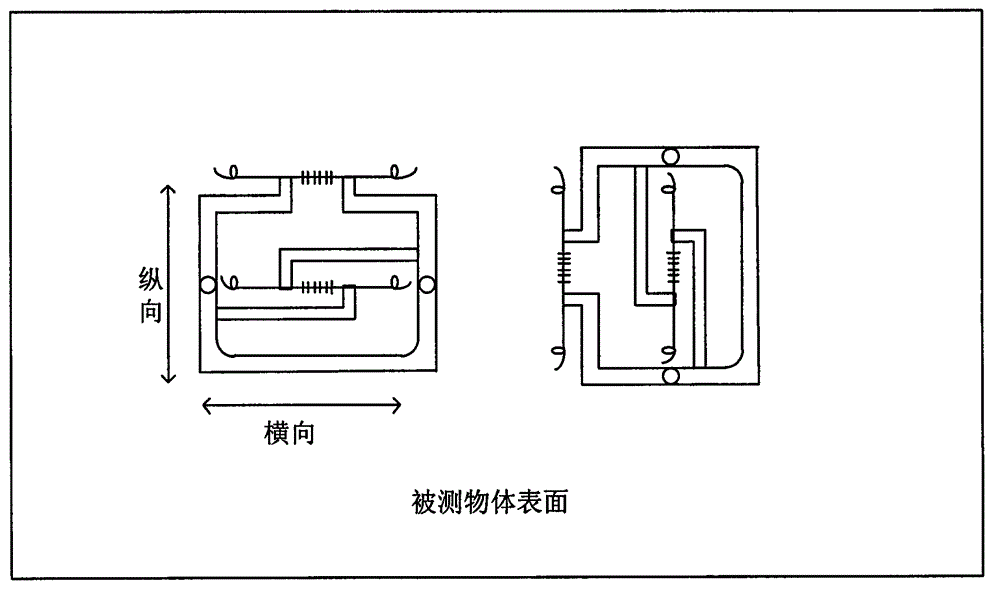

[0017] A material surface strain fiber grating reverse differential detection sensor device according to the present invention comprises a fiber Bragg grating (1), a fiber Bragg grating (2), a strain conduction arm (3), a strain extension arm (4), a screw Column welding foot (5), upper right angle reverse arm (6), lower right angle reverse arm (7) and base (8).

[0018] The strain conduction arm (3), the strain extension arm (4), the stud welding foot (5), the upper right-angle reverse arm (6), the lower right-angle reverse arm (7) and the base (8) are integrated metal structure.

[0019] The materials of the strain conduction arm (3), the strain extension arm (4), the stud welding leg (5), the upper right-angle reverse arm (6), the lower right-angle reverse arm (7) and the base (8) should be Choose materials that are consistent with the measured object to avoid thermal stress caused by differences in thermal expansion coefficients of different materials when the external tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com