Well repair working platform

A working platform and workover technology, which is applied in the direction of drilling equipment, earthwork drilling and production, supporting devices, etc., and can solve problems that affect the service life of connecting pipes and blowout preventers, and the tilt of the main body of the platform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0018] In the present invention, the terms "first" and "second" are mainly used to distinguish different components, but do not specifically limit the components.

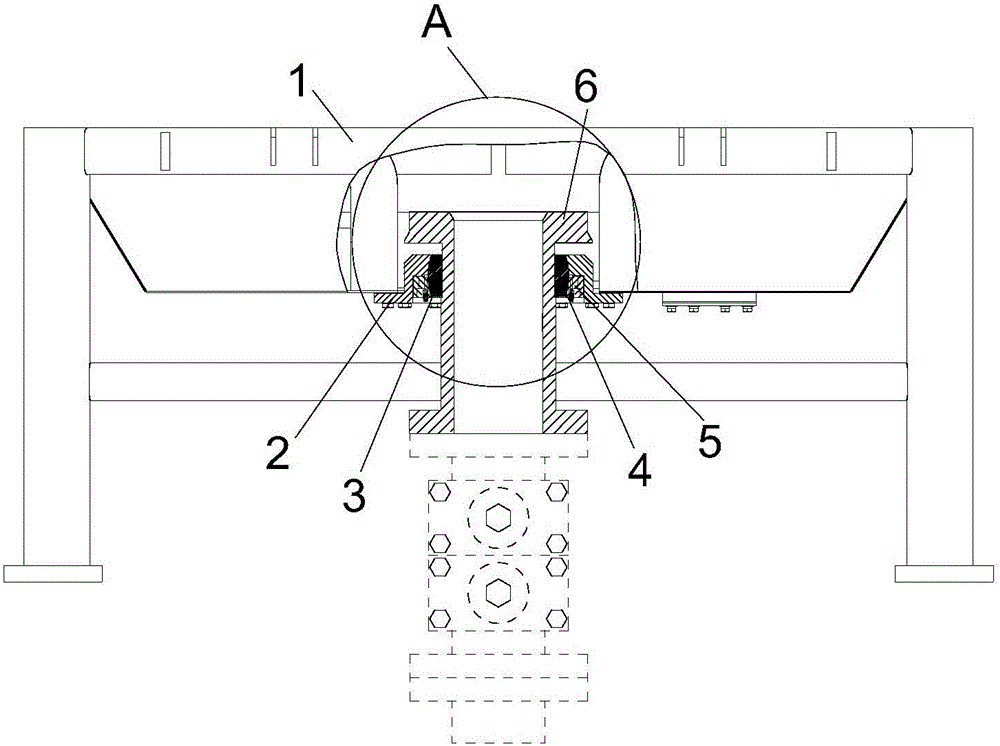

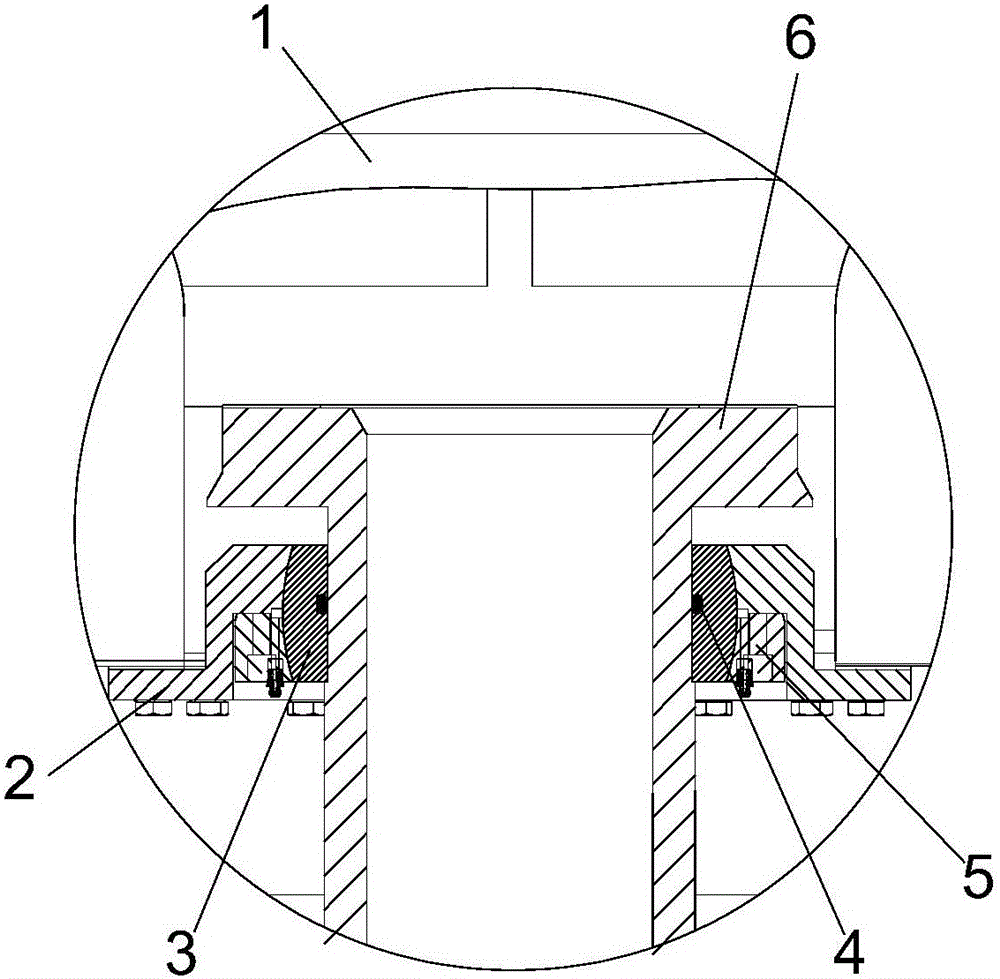

[0019] Such as figure 1 and figure 2 As shown, the workover work platform of this embodiment includes a platform main body 1, on which a pipe string operation port is arranged, and the pipe string operation port is connected with a connecting pipe 6, and the connecting pipe 6 is movably connected to the platform through a ball hinge mechanism. On subject 1.

[0020] Specifically, the ball hinge mechanism includes a first fixed ring 3 sleeved on the outer wall of the connecting pipe 6, a second fixed ring 2 and a pressure plate 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com