A large-aperture construction raise drilling rig

A raise drilling rig and large-aperture technology, which is applied to driving devices, drill pipes, drill pipes, etc. for drilling in the wellbore, can solve the problems of low safety factor and complex structure, and achieves improved safety, simple operation, and improved work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

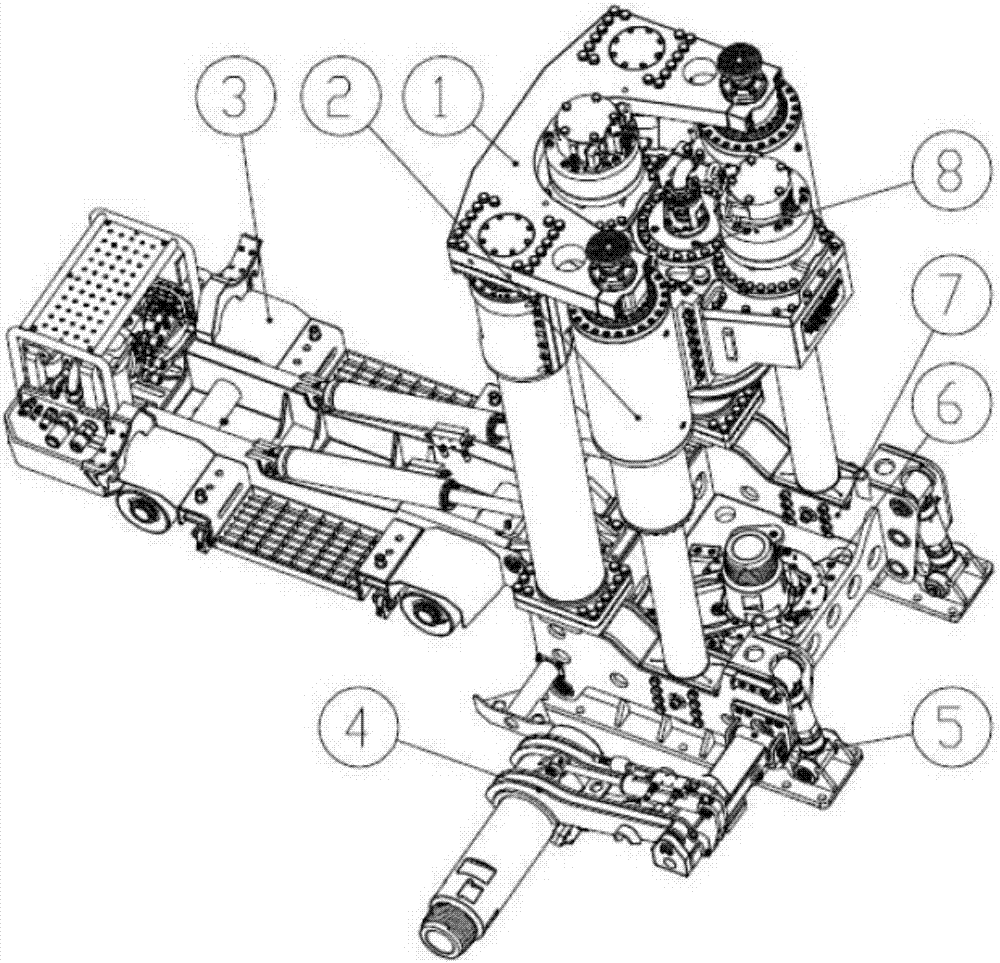

[0036] Such as figure 1 As shown, a large-aperture construction patio drilling rig provided by the present invention includes a propulsion mechanism 2, a manipulator assembly 4, a main engine chassis 3, an adjustment mechanism 5, a dynamic plate insertion mechanism 6, a reduction box assembly 8, a top plate 1 and a base 7 , the reduction box assembly 8 is connected to the propulsion mechanism 2, the two ends of the propulsion mechanism 2 are respectively connected to the top plate 1 and the base 7, and the base 7 is respectively connected to the adjustment mechanism 5, the main engine The chassis 3 is connected with the manipulator assembly 4, and the dynamic board mechanism 6 is arranged on the base 7.

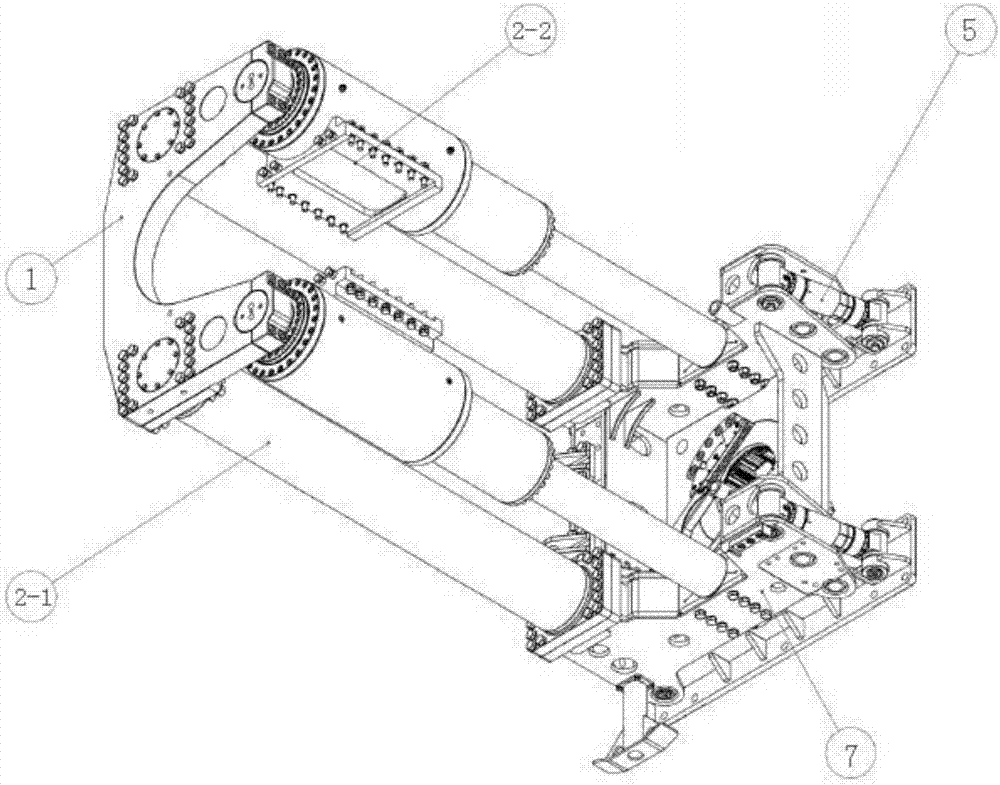

[0037] Such as figure 2 As shown, the propulsion mechanism 2 includes a propulsion cylinder 2-1 and a column 2-2. Both the base 7 and the top plate 1 are positioned by a guide rod positioning sleeve, one end of the propulsion cylinder 2-1 is bolted to the base 7, the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com