Workshop sealing door

A technology for sealing doors and workshops, which is applied in the field of workshop doors, which can solve the problems of affecting the sealing effect, easy damage, and damage to the rubber strip, and achieve the effect of prolonging the service life and good sealing effect around the periphery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

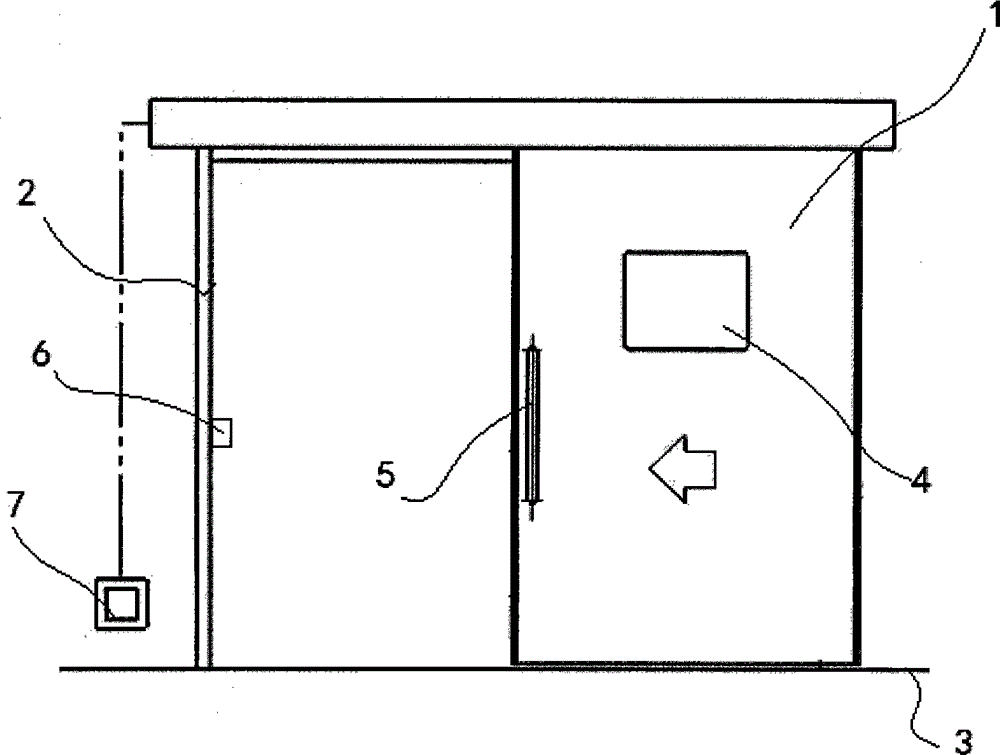

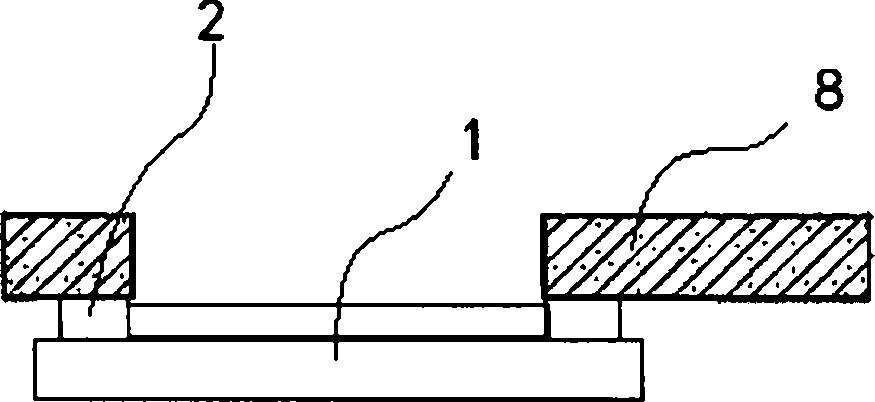

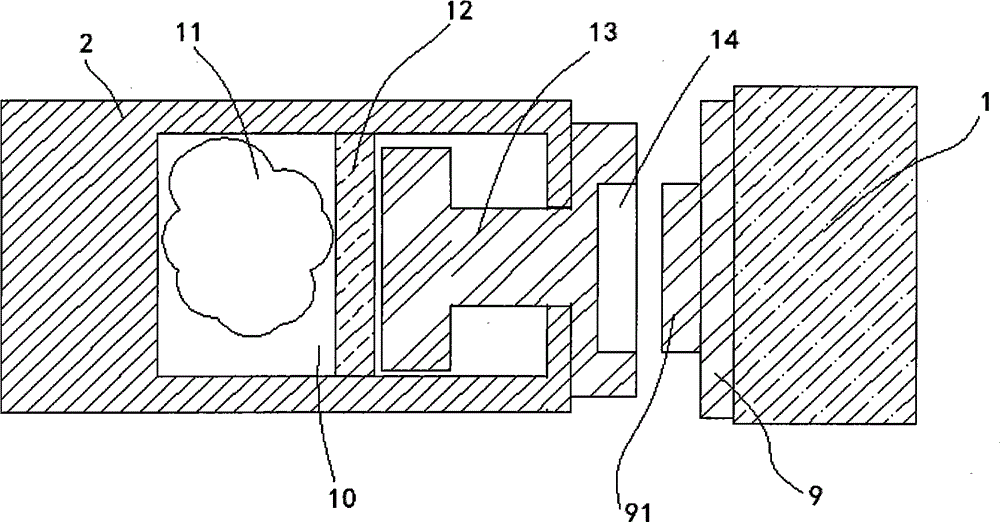

[0014] see Figure 1~3 , a workshop airtight door, comprising a door body 1, the door body 1 is arranged outside the door frame 2 at the door of the workshop, the door frame 2 is fixed on the wall body 8 of the workshop, and a door opening is left in the middle, and the upper and lower parts of the door frame are arranged There is a guide wheel device 3 for the linear movement of the door body 1, an I-shaped door frame sealing strip 13 is provided around the outside of the door frame, and a door frame sealing strip 13 is provided on the inside of the door body corresponding to the door frame sealing strip 13. The door body sealing strip 9, the door frame sealing strip 13 is installed in the groove 10 provided on the door frame 2, the groove 10 is also provided with an air bag 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com