Soft magnetic steel having excellent forging characteristic soft magnetic part and method of manufacturing the same

A manufacturing method and forging technology, applied in the field of soft magnetic steel, can solve the problems of uneven structure, material forging deterioration, abnormal grain growth, etc., to minimize the limitation of processing conditions, improve forging, and expand the scope of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

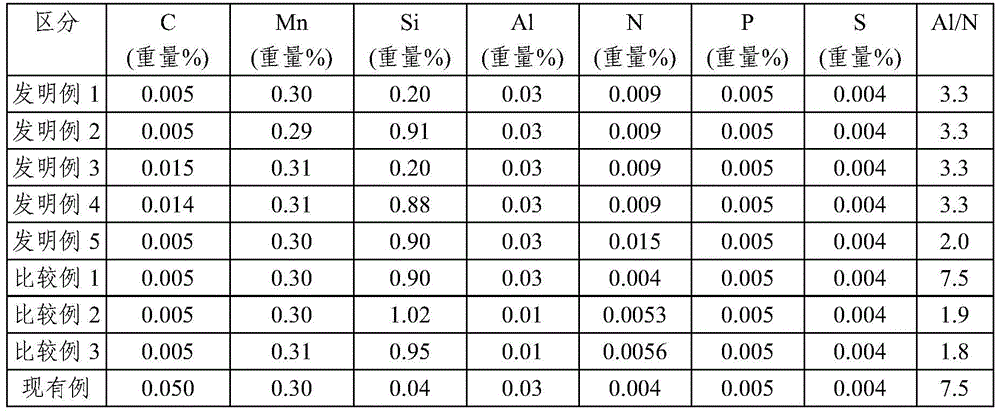

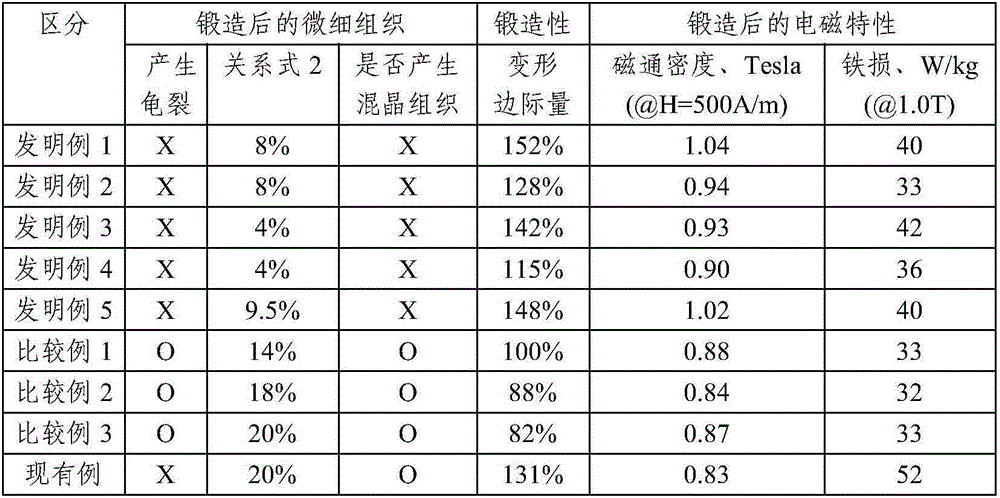

[0072] Hereinafter, the present invention will be described more specifically by way of examples. However, the following examples are merely examples for further explaining the present invention in detail, and are not intended to limit the scope of claims of the present invention. The scope of the claims of the present invention is determined based on the content described in the claims and the content reasonably derived therefrom.

[0073] Steels having the composition systems described in Table 1 below were cast. Then, heating at a temperature of 1150° C. and hot rolling were performed according to a general method to manufacture rods each having a diameter of 50 mm. The hot-rolled bar with a diameter of 50 mm was then cooled at a temperature of 1050°C at a rate of 5°C / sec.

[0074] Claw poles for automotive alternator rotors were fabricated from the bars. A bar with a diameter of 50 mm was cut with a weight of 1.2 kg, heated at a temperature of 1200° C., and hot forged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com