Acetylene gas generator taking calcium carbide dust as raw material

A technology of acetylene gas and calcium carbide, which is applied to acetylene generators, parts of acetylene gas generators, generators with calcium carbide submerged in water, etc., can solve the problems of small evaporation, large amount of rainwater, and land occupation, etc., and achieve Eliminate safety hazards, ensure safe production, and benefit the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

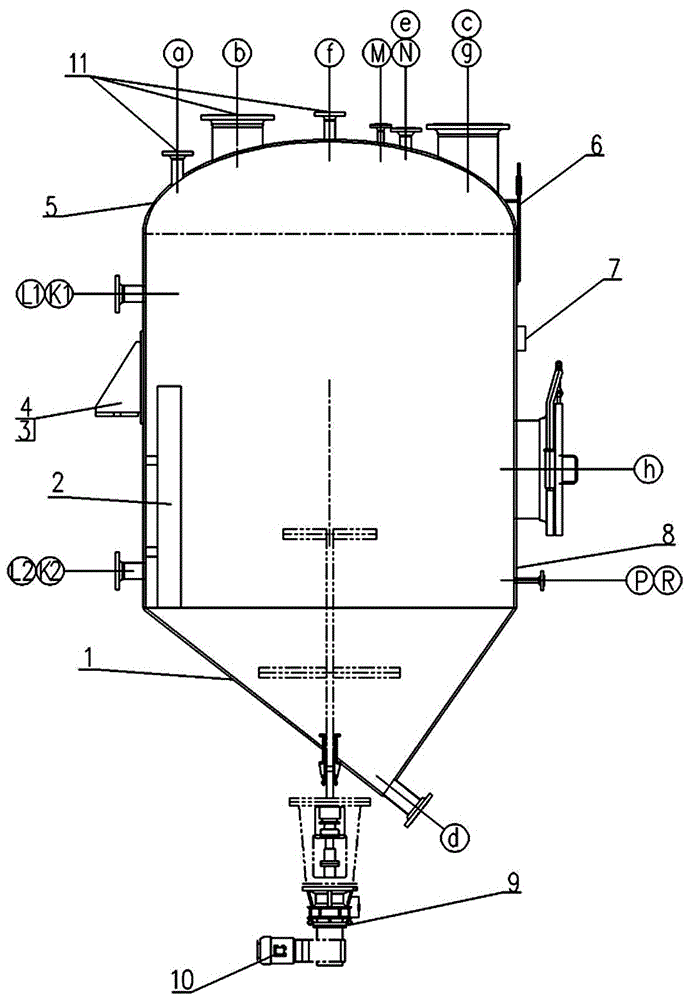

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

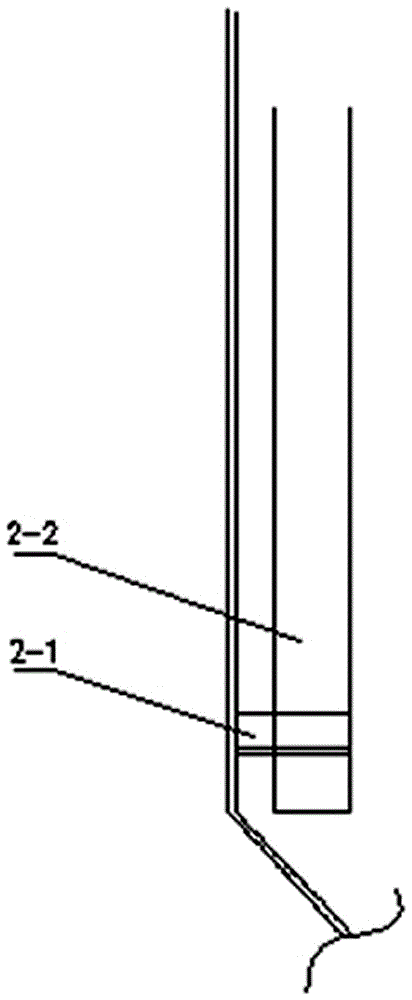

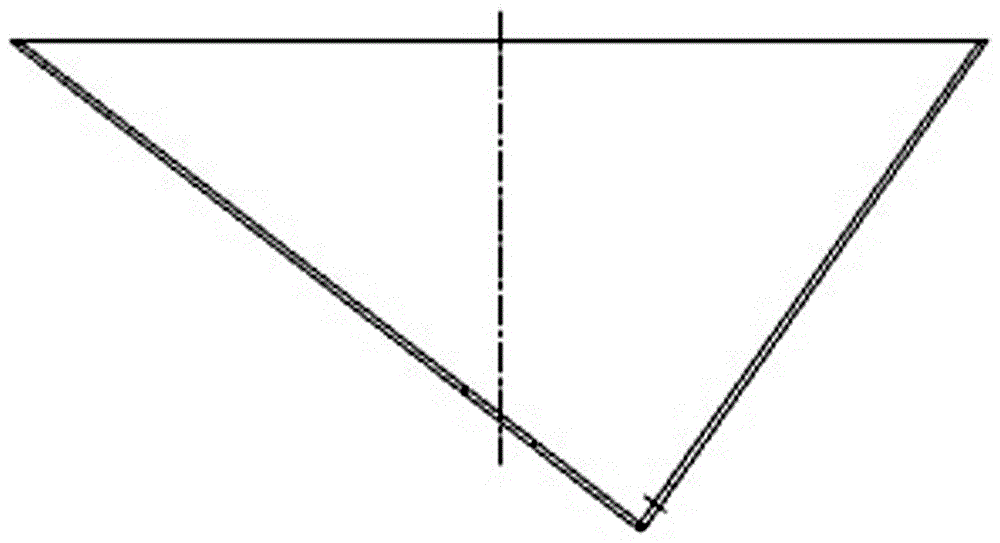

[0023] Such as figure 1 , figure 2 , image 3 As shown, an upper head 4 is welded and connected to the upper part of the cylinder 8, and the upper head 5 is provided with a slurry circulation pipe interface a, and also provided with calcium carbide dust inlet b, acetylene gas outlet c, nitrogen inlet e, exhaust Gas port f, explosion-proof port g, remote pressure gauge port M, on-site pressure gauge port N, connecting short pipe and flange 11; baffle plate 2-2 is installed on the inner wall of cylinder body 8; ear type is fixed on the outer wall of cylinder body 8 The support 3 and the support plate 4 are also provided with a manhole h; the outer wall of the cylinder 8 is also provided with an on-site liquid level gauge port L1, an on-site liquid level gauge port L2, a remote liquid level gauge port K1, and a remote liquid level gauge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com