Pre-glued dry type trademark process technology

A process technology and pre-gluing technology, applied in the field of trademarks, can solve the problems of non-compliance with environmental protection requirements, consumption of adhesives, poor labeling quality, etc., and achieve the effect of being conducive to wide popularization and application, convenient storage, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

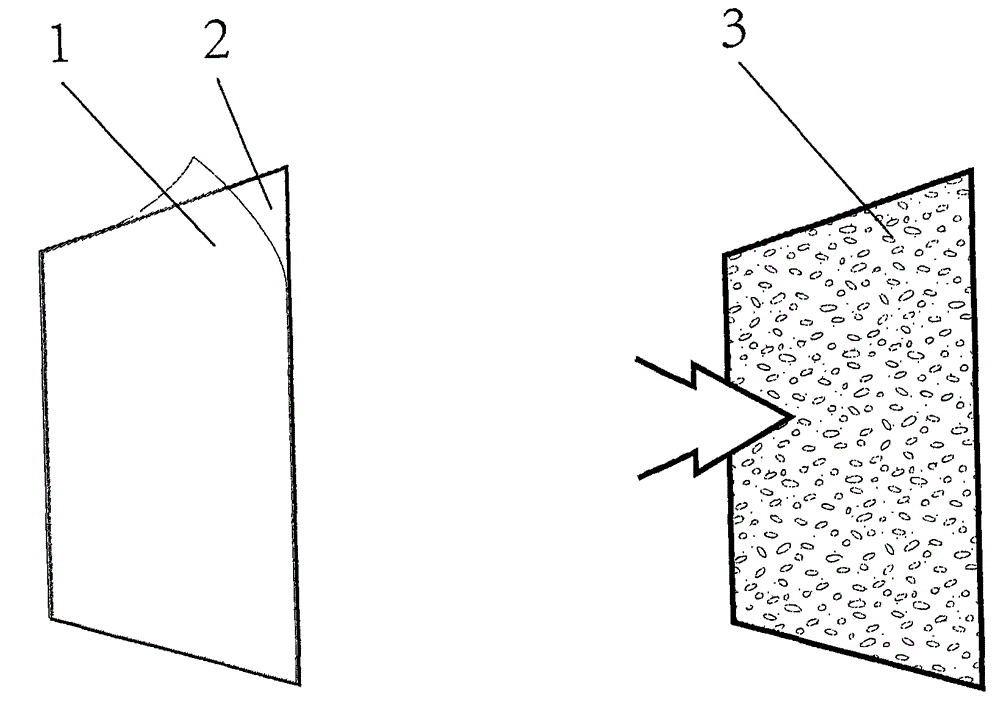

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0031] A pre-applied glue dry-type trademark process technology, the front side of the trademark carrier layer needs to print the trademark content, and the back side of the trademark carrier layer is pre-coated with one of polyvinyl alcohol glue, casein glue, and starch dextrin glue. Dry glue layer, the dry glue layer is kept dry at ordinary times, so as to make a pre-coated dry-type trademark. When the pre-coated dry-type trademark is used, the spray liquid in the spray device sprays the dry-type The adhesive layer is sprayed, the glue of the dry adhesive layer is activated and viscous to prepare for labeling, and then the activated and viscous dry adhesive layer is pasted on the bottle body.

[0032]In the pre-applied glue dry-type trademark process technology, the material of the trademark carrier layer is a material select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com