Emulsion for stonelike paint and stonelike paint with emusion as film forming matter

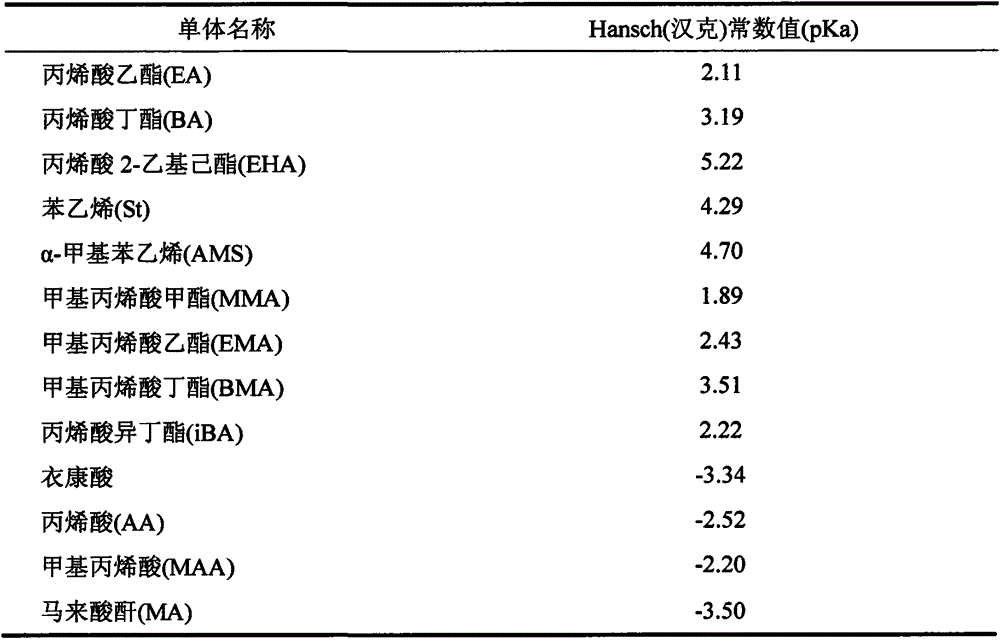

A real stone paint and emulsion technology, applied in the field of real stone paint, can solve the problems of color distortion when exposed to water, paint film can not be dried, yellowing resistance and hardness building speed are not completely solved, etc., to reduce water absorption and ensure permanent recovery. , the effect of shortening the hardness build-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below through specific embodiments.

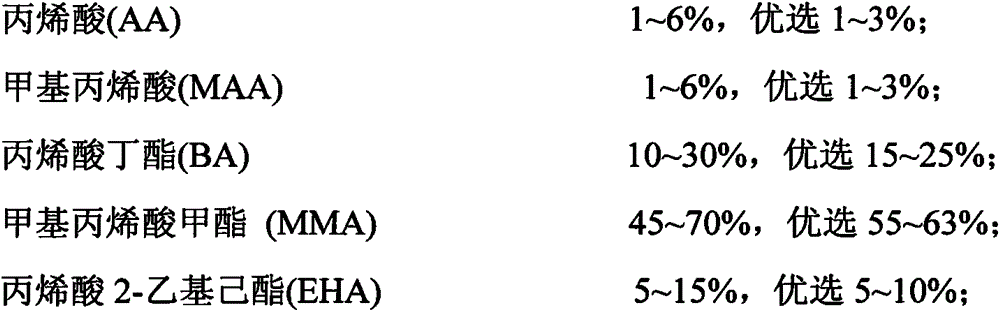

[0051] Attached table Hank's constant (Hansch) of commonly used monomers**

[0052]

[0053] **Hansch and Fujita. Lange' handbook, 15th edition; or Hansch and Fujita. Journal of American Chemical Society, 1964, 86:1616-1626;

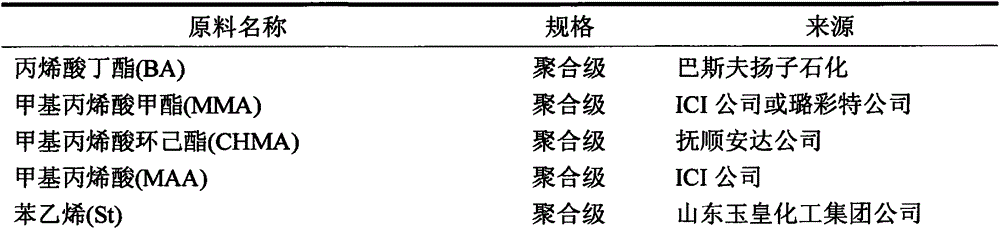

[0054] Table 1 Monomer raw materials used in the examples

[0055]

[0056]

[0057] Table 2 Additives and pigments and fillers for coatings

[0058]

[0059] Main Analytical Instruments

[0060] Table 3 Main experimental instruments and equipment

[0061]

[0062] Preparation of seed emulsion:

[0063] Table 4 Composition of seed emulsion

[0064]

[0065] ①Pre-emulsification: Add measured deionized water into a 5000ml three-neck flask, start stirring, add the measured emulsifier, start adding the measured monomer dropwise after 15 minutes, and continue high-speed stirring to emulsify for about 1 hour;

[0066] ②Polymerization: Add deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com