High anti-dazzle glass and preparing technology

An anti-glare glass and preparation technology, which is applied in the glass field, can solve the problems of coated glass such as not being durable, snowflake-like flickering, and low definition, and achieve good anti-glare effect, reduced etching depth, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare etching solution:

[0034] The parts by weight of etching solution consist of:

[0035]

[0036] Mix the raw materials in the above parts by weight uniformly at room temperature to obtain an etching solution.

[0037] Preparation of single-sided high anti-glare glass:

[0038] (1) Clean the glass surface with water, remove impurities, and dry;

[0039] (2) Cover the side that does not need to be etched with stickers;

[0040] (3) The etchant is sprayed on the glass surface by spraying method, then rinsed with distilled water, and dried; the spraying condition is: the spraying head is sprayed for 120-180 seconds.

[0041] (4) putting the etched glass surface into a mixed solution of hydrofluoric acid (mass concentration 20%) and sulfuric acid (mass concentration 30%) with a volume ratio of 4:1 at 25°C for 120 seconds, and then Rinse with water and allow to dry.

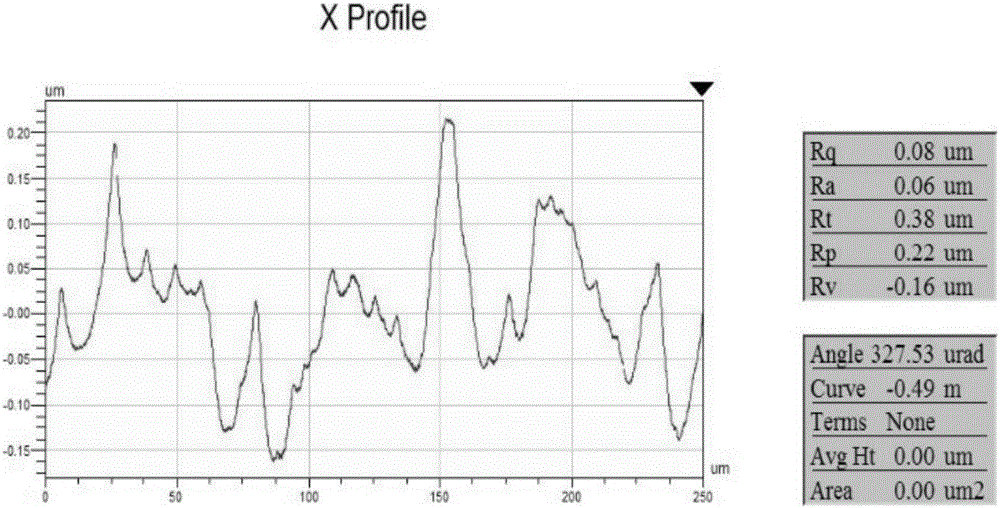

[0042] The SEM image of the prepared high anti-glare glass is as follows figure 1 As shown, ...

Embodiment 2

[0045] Prepare etching solution:

[0046] The parts by weight of etching solution consist of:

[0047]

[0048] Mix the raw materials in the above parts by weight uniformly at room temperature to obtain an etching solution.

[0049] Preparation of single-sided high anti-glare glass:

[0050] (1) Clean the glass surface with water, remove impurities, and dry;

[0051] (2) Cover the side that does not need to be etched with stickers;

[0052] (3) The etchant is sprayed on the glass surface by spraying method, then rinsed with distilled water, and dried; the spraying condition is: the spraying head is sprayed for 120-180 seconds.

[0053] (4) putting the etched glass surface into a mixed solution of hydrofluoric acid (mass concentration 20%) and sulfuric acid (mass concentration 30%) with a volume ratio of 4:1 at 25°C for 120 seconds, and then Rinse with water and allow to dry.

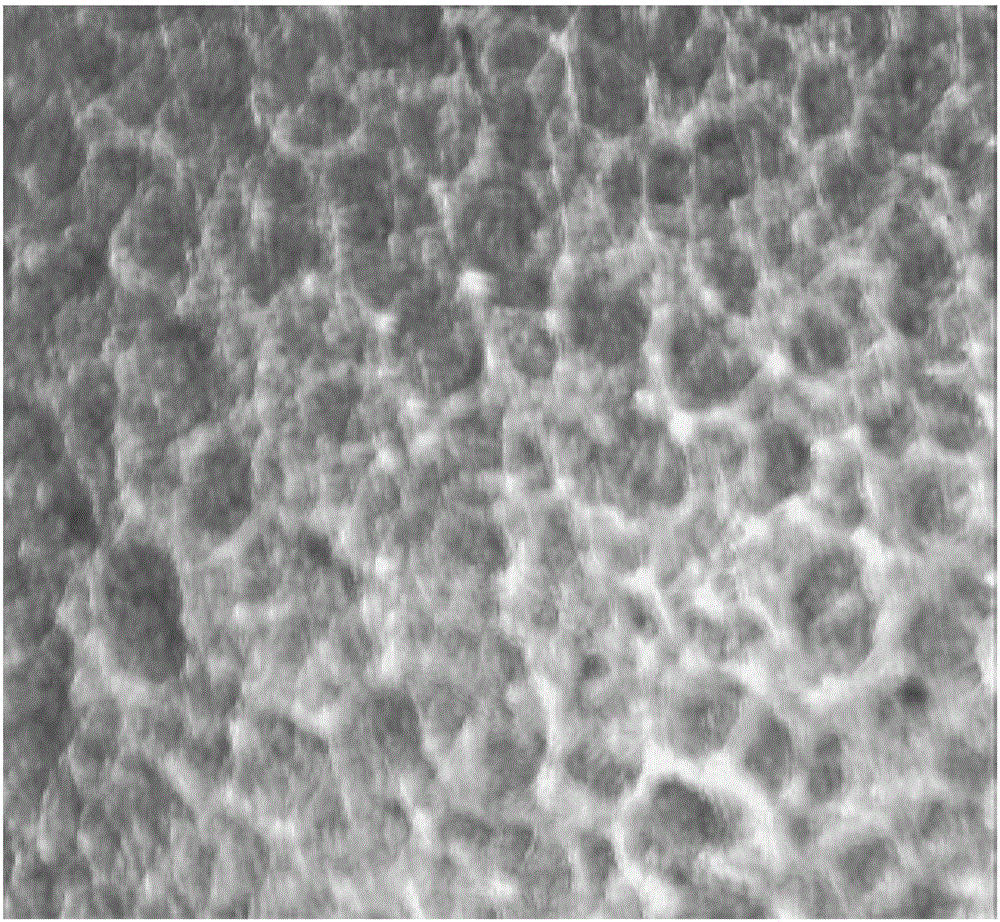

[0054] The SEM image of the prepared high anti-glare glass is as follows figure 2 shown. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com