Method for preparing photoelectric material CsPbBr3

A technology of photoelectric materials and raw materials, which is applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of restricting the mass production of CsPbBr3, high price, etc., and achieve the problem of overcoming instability, low price, and simple preparation of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, 0.758g Pb(CH 3 COO) 2 Dissolve in 8 mL of HBr solution at 30 °C; dissolve 0.851 g of CsBr in 4 mL of HBr at 30 °C 2 O and 8mL HBr solution in a mixed solution. Mix the two prepared solutions, where Cs + with Pb 2+ The molar ratio is 2:1, and the orange-red CsPbBr is obtained after reaction at 40 °C for 1 h 3 Precipitate, filter the precipitate and wash it repeatedly with absolute ethanol 3 times, then place the washed product in a vacuum oven and dry it at 50°C for 3 hours to obtain CsPbBr 3 .

[0033] The mass percent concentration of the HBr solution mentioned in this embodiment is 48%.

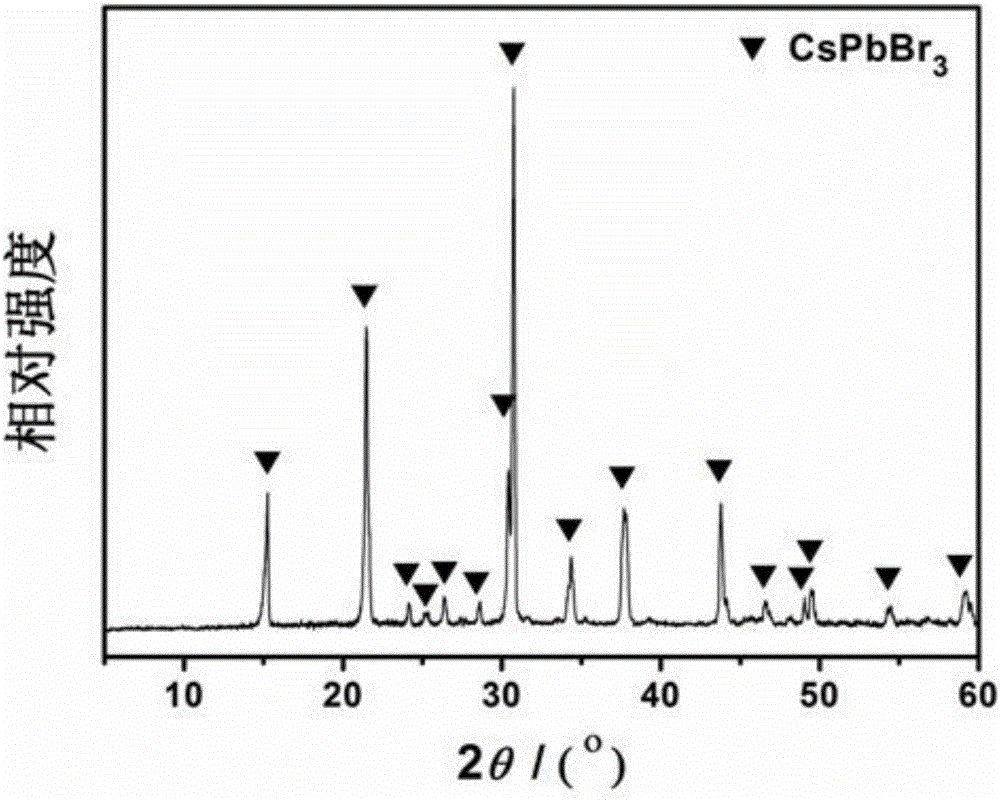

[0034] figure 1 For the prepared CsPbBr 3 X-ray diffraction pattern of . All diffraction peaks correspond to CsPbBr 3 The standard XRD spectrum of the product shows high purity and no impurity phase.

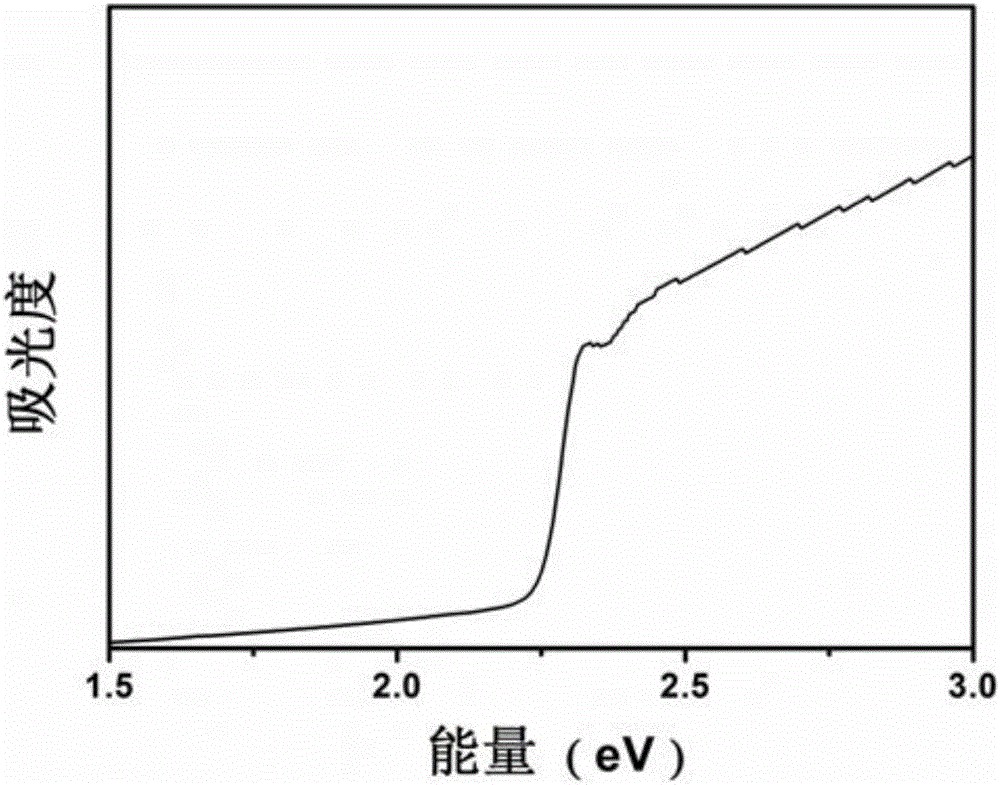

[0035] figure 2 For the prepared CsPbBr 3 The UV-Vis absorption spectrum of figure 2 It can be calculated that the prepared CsPbBr 3 The forbidden band width is 2...

Embodiment 2

[0037] First, 0.758g Pb(CH 3 COO) 2 Dissolve in 8 mL of HBr solution at 40 °C; dissolve 2.553 g of CsBr in 12 mL of HBr at 30 °C 2 O and 12mL HBr solution in a mixed solution. Mix the two prepared solutions, where Cs + with Pb 2+ The molar ratio is 6:1, and the orange-red CsPbBr is obtained after 1 h reaction at 40 °C 3 Precipitate, filter the precipitate and wash it repeatedly with absolute ethanol 3 times, then place the washed product in a vacuum oven and dry it at 60°C for 2 hours to obtain CsPbBr 3 .

[0038] The mass percent concentration of the HBr solution mentioned in this embodiment is 48%.

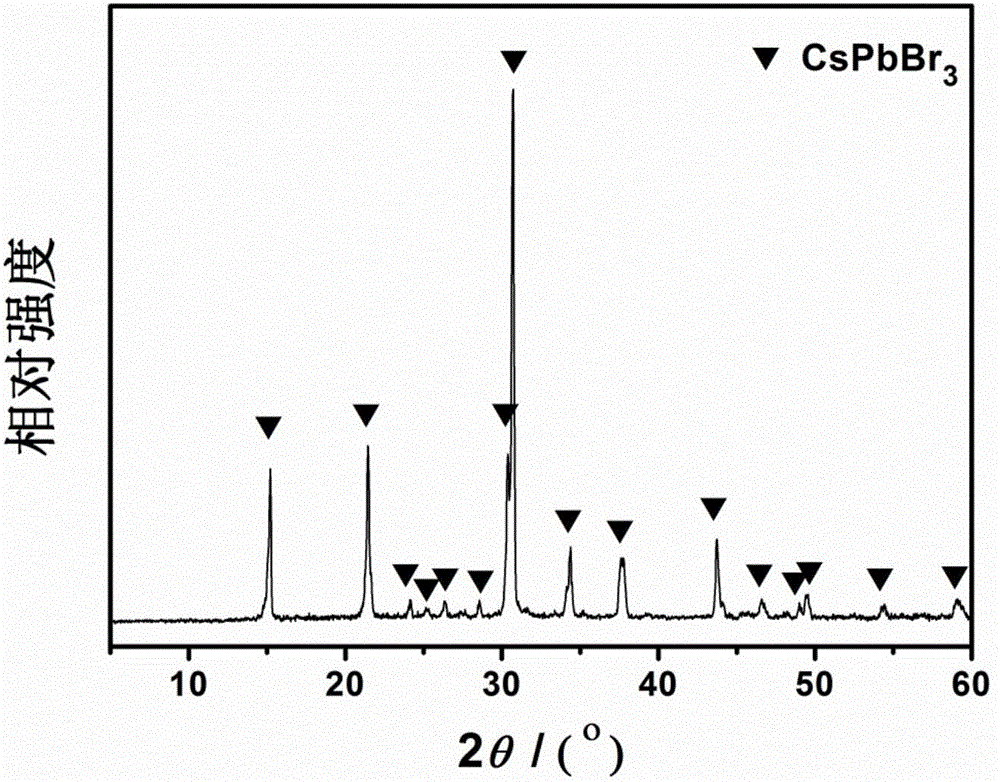

[0039] image 3 For the prepared CsPbBr of embodiment two 3 X-ray diffraction pattern of . All diffraction peaks correspond to CsPbBr 3 The standard XRD spectrum of the product shows high purity and no impurity phase.

[0040] Adopt the method proposed by the present invention to prepare CsPbBr 3 , it is necessary to precisely control the Cs in the mixed solution 2+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com