An anti-error device for filter triangular bracket packaging

A triangular bracket and filter technology, applied in packaging, transportation and packaging, single objects, etc., can solve problems such as difficult to distinguish, achieve convenient operation, reduce mold replacement time, and increase production output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

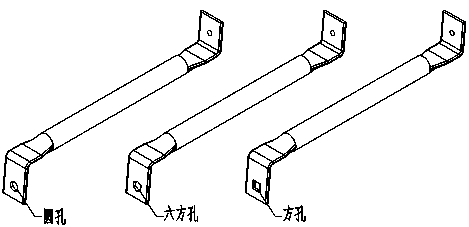

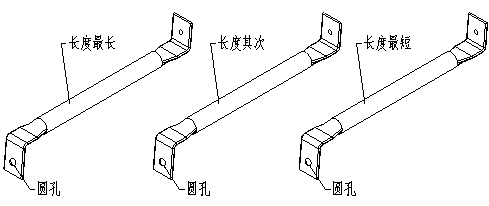

[0013] 1. Use a punch to punch round holes at one end of the galvanized pipe of the same length in the triangular bracket.

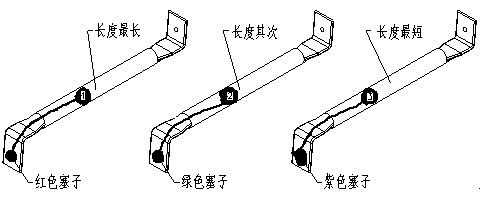

[0014] 2. After punching the round hole and cleaning it, insert a plug of the same color as required.

[0015] 3. According to the color of the plug, three kinds of galvanized pipes of different lengths are packaged as a set of triangular brackets; the foam plastic cloth is placed on both ends of the galvanized pipe, and part of the colored lines and the connected digital signs are exposed on the Outside. Pack galvanized pipes of different lengths uniformly.

[0016] 4. When assembling on site, distinguish galvanized pipes of different lengths according to the colored lines exposed on the package of the tripod galvanized pipes and the digital signs, and install the galvanized pipes with three different colored lines and digital signs. As a set, assemble into a tripod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com