Water surface diversion, floater collection and rubbish recovery ship

A technology of sweeping boats and diversion pipes, which is applied to the cleaning of open water surfaces, water conservancy projects, special-purpose ships, etc. It can solve the problems of stuck floating objects, difficult maintenance, low efficiency, etc., and achieve a reduction in the height of the centerline of the shaft system , Improve propulsion efficiency, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

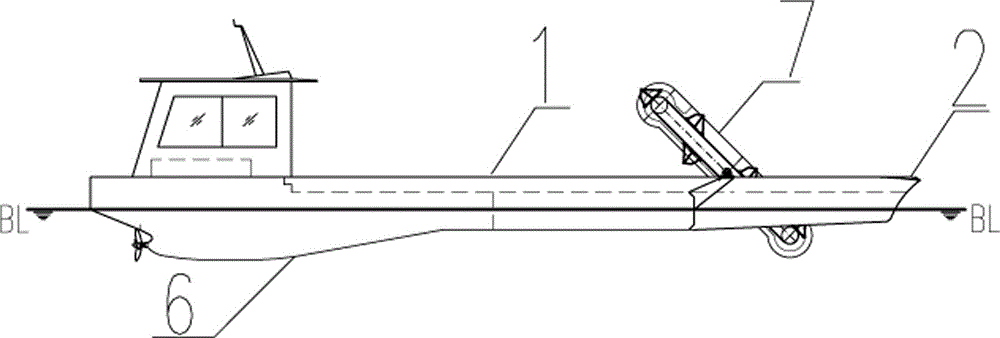

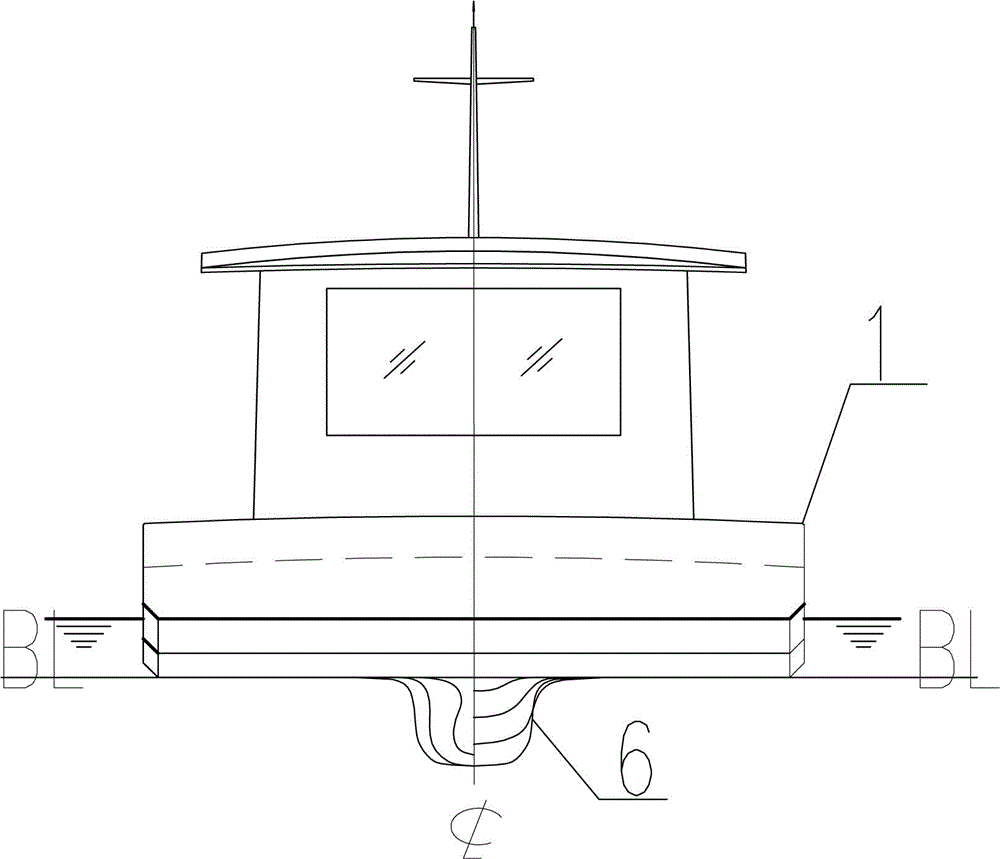

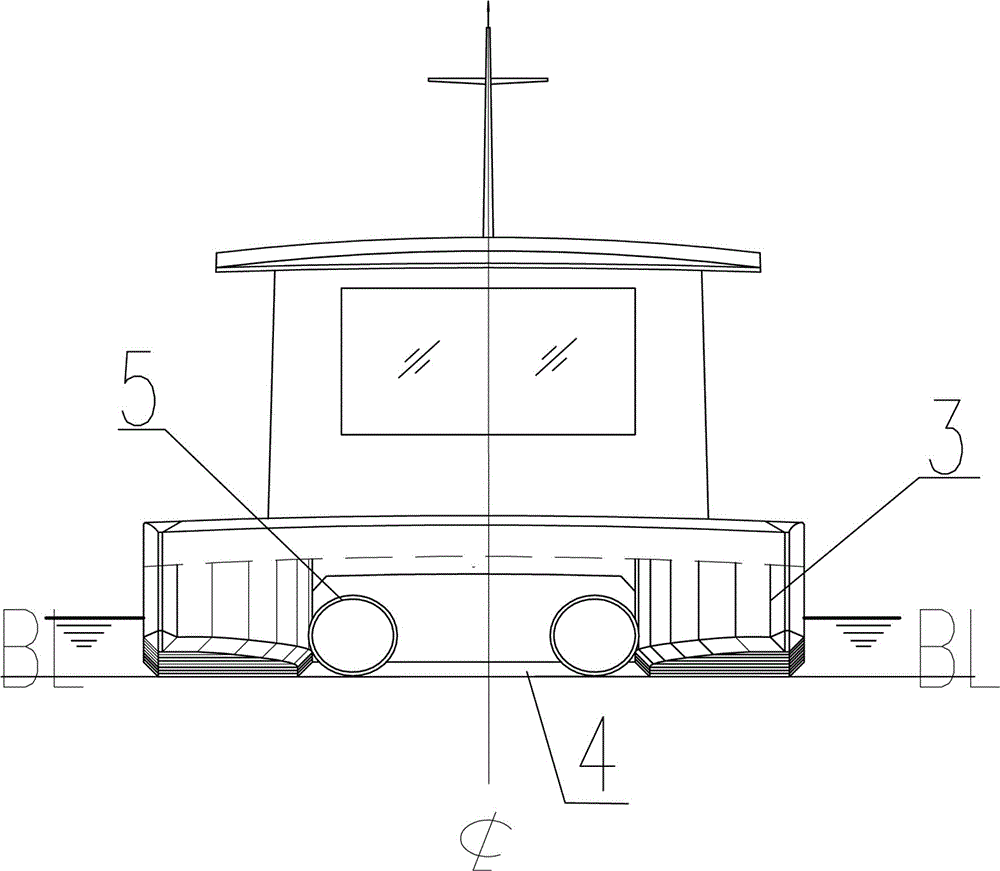

[0024] Such as figure 1 , 2 , 3, 4, a kind of surface diversion drift collection and sweeping ship comprises hull 1 and the drift collection well 2 that is located at the bow of hull 1, cargo hold 12 is provided on hull 1, and convex belly ball tail 6 is provided on the bottom surface of hull 1 tail , the propeller shaft is connected to the engine in the hull 1 through the stern tube assembly through the convex ball tail 6, and the bow of the hull 1 is provided with a collection device 7, such as Figure 6 Among them, the collection device 7 includes a belt conveyor 8 and a collection bucket 9 located on the belt conveyor 8. The belt conveyor 8 is fixed on the frame 10 through a movable rotating shaft. During work, the belt conveyor 8 of the collection device 7 drives The collecting bucket 9 rotates to collect the floating matter in the floating well 2 into the cargo compartment 12, and the angle of the belt conveyor 8 can also be rotated as required, preferably as Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com