Manganese steel coated titanium alloy composite tank vehicle track shoe production method

A production method, titanium alloy technology, applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of cumbersome preparation process, high preparation cost, poor cold resistance, etc., reduce raw material loss, improve overall strength, improve The effect of cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

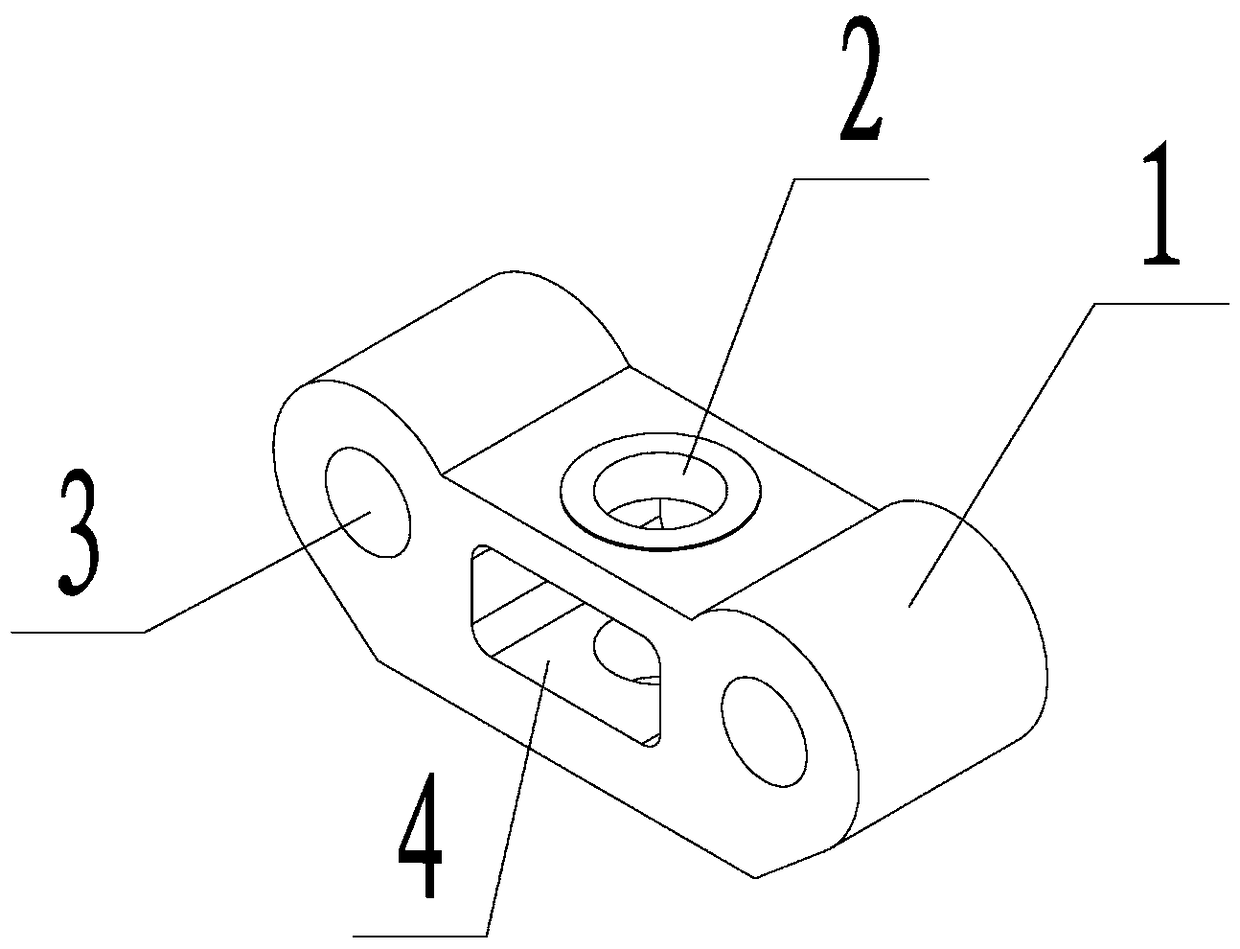

[0017] The following combination figure 1 , the content of the present invention will be described in detail through specific embodiments. The manganese-steel-clad titanium alloy composite tank track shoe includes a track shoe main body provided with a weight-reducing hole 4 and ears 1 symmetrically arranged on both sides of the track shoe main body, and the track shoe main body is provided with an assembly hole I2 through the weight-reducing hole. , There is an assembly hole II3 in the same direction as the weight reduction hole on the ear, and the track shoes are manganese steel metal layer and titanium alloy metal layer from outside to inside.

[0018] The composition ratio of the titanium alloy pipe is: aluminum 3.0~5.5wt%, alum 2.0~3.0wt%, iron 1.0~2.2wt%, oxygen 0.01~0.04wt%, titanium balance.

[0019] The composition ratio of manganese steel bar is: C0.2wt%~0.3wt%; Mn4.6wt%~5.2wt%; B1.2wt%~1.6wt%; Si0.25wt%~0.35wt%; Cr0.2wt% ~0.3wt%; Ni0.2wt%~0.4wt%; Nb0.004wt%~0.006w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com