Electrical cabinet trolley

A trolley and electrical cabinet technology, applied in trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of reducing construction efficiency, injury to workers, overturning of trucks, etc., and achieve reasonable structural design, improve construction efficiency, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

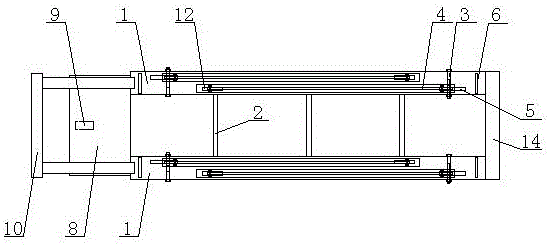

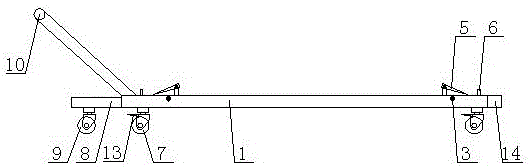

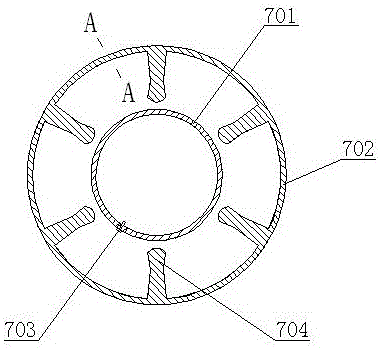

[0036] Such as Figure 1 to Figure 7As shown, the present invention includes two load-bearing frames 1 arranged in parallel, and the two load-bearing frames 1 are fixedly connected by three connecting rods 2 arranged horizontally. The connecting rod 2 is composed of a sleeve 201 and a sleeve rod 202 which are socketed together, and a positioning pin shaft 203 is screwed to the outside of the sleeve 201 . Both ends of each bearing frame 1 are movably connected to one end of a support rod 4 via a rotating shaft 3 . The two supporting rods 4 of each load-bearing frame 1 are relatively staggered, and a hinged baffle plate 5 is arranged on each supporting rod 4 near its rotating shaft 3 inside, and each supporting rod 4 is opposite to its rotating shaft 3. The part is hinged with a support plate 12. A fixing plate 6 matched with the baffle plate 5 is provided on the bearing frame 1 outside each rotating shaft 3 . The positions of the two rotating shafts 3, the two baffle plates ...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the outer tread of the tire body includes the following raw materials in parts by weight: 95 parts of solution-polymerized styrene-butadiene rubber, 76 parts of rare earth butadiene rubber, 44 parts of carbon black, 5 parts of white carbon black, anti- 14 parts of tearing resin, 22 parts of active filler, 4 parts of anti-aging agent, 3 parts of sulfur, 2 parts of stearic acid, 2 parts of aromatic oil, 3 parts of indirect zinc oxide and 3 parts of dispersant.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the outer tread of the tire body includes the following raw materials in parts by weight: 100 parts of solution polystyrene butadiene rubber, 80 parts of rare earth butadiene rubber, 50 parts of carbon black, 10 parts of white carbon black, anti- 20 parts of tearing resin, 25 parts of active filler, 6 parts of anti-aging agent, 5 parts of sulfur, 3 parts of stearic acid, 6 parts of aromatic oil, 4 parts of indirect zinc oxide and 6 parts of dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com