Vertical-horizontal composite pentahedron gantry machining center

A machining center and pentahedron technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing accuracy, low production efficiency, insufficient rigidity, etc. The effect of high precision and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

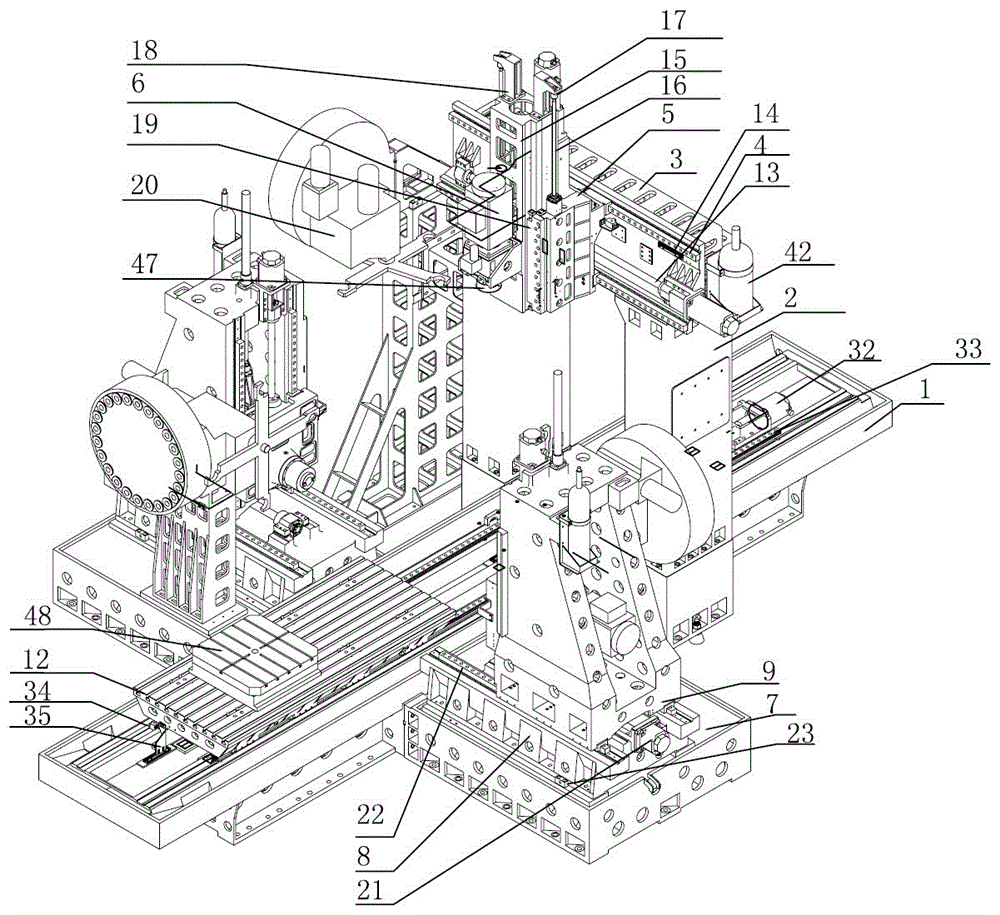

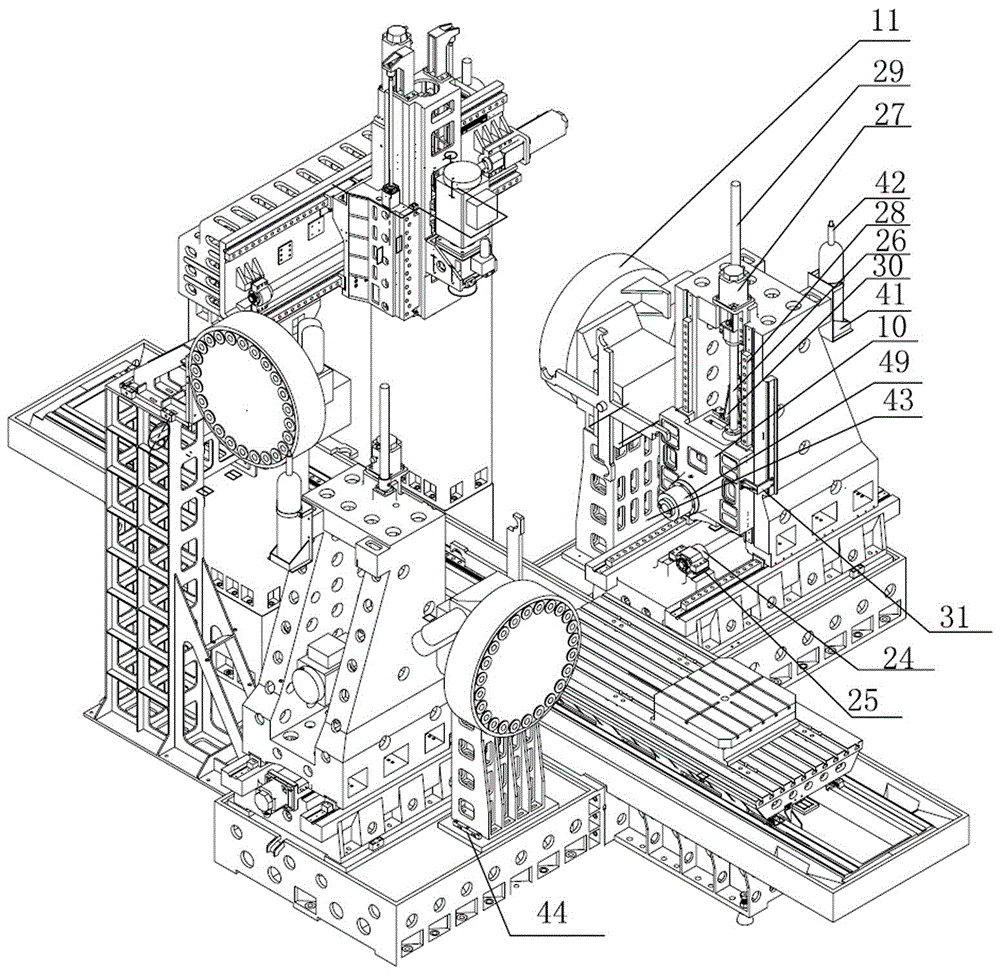

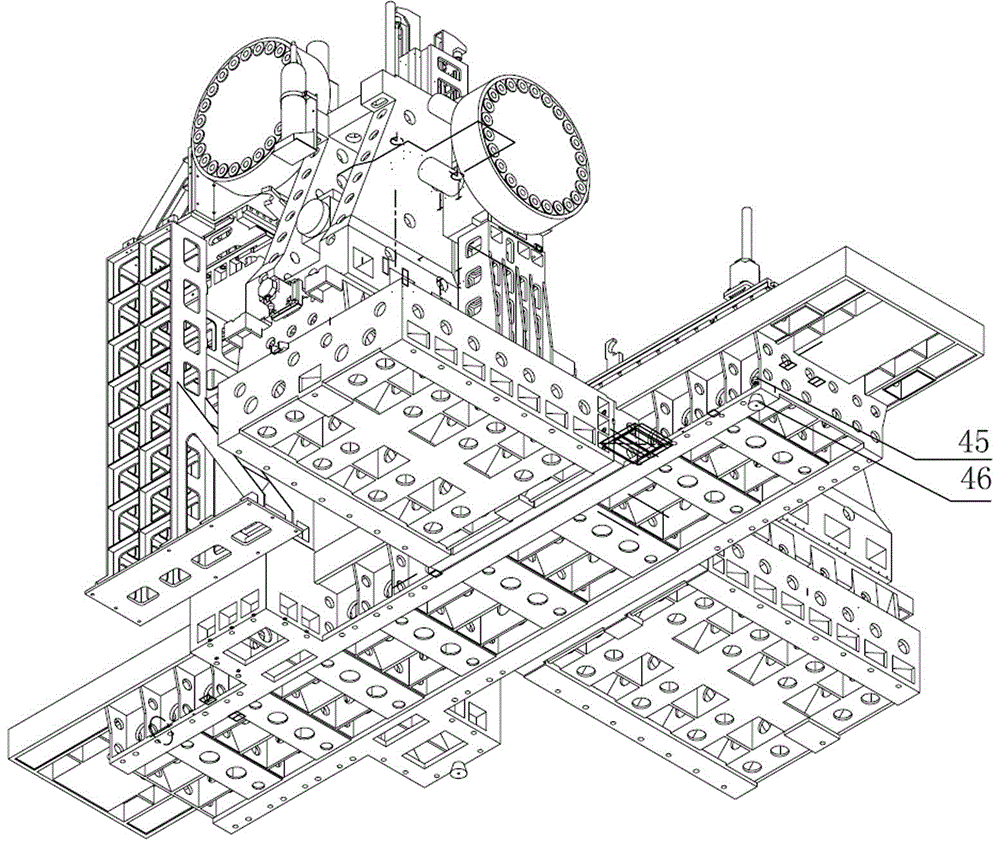

[0026] Embodiment 1: The vertical and horizontal compound gantry processing center of this example, such as figure 1 , figure 2 , image 3, including a base 1, a column 2, the upper end of the column is fixedly connected with a beam 3, the beam is movably connected with one or more saddles 5 through the beam line rail 4, a ram is arranged on the saddle, and a vertical headstock 6 is arranged on the ram With the vertical spindle 47, the ram is provided with a screw driving device; one or more horizontal shaft bases 7 are fixed on one or both sides of the base, and the horizontal shaft base is provided with a horizontal shaft bed and a horizontal shaft saddle 8, The horizontal shaft saddle is fixed with a horizontal shaft column 9, and the horizontal shaft column is connected to the horizontal shaft headstock 10 and the horizontal main shaft 49 through a screw drive device, and a horizontal shaft tool magazine 11 is fixed on one side of the horizontal shaft base; The longitud...

Embodiment 2

[0028] Embodiment 2: The vertical and horizontal compound gantry processing center of this example, such as Figure 4 , including a base 1, a column 2, the upper end of the column is fixedly connected with a beam 3, the beam is movably connected with a saddle 5 through the beam rail 4, a ram and a vertical headstock 6 are connected to the saddle, and a screw rod is arranged on the saddle Drive device; one or more horizontal shaft bases 7 are fixed on one side of the base, and the horizontal shaft base is provided with a horizontal shaft bed and a horizontal shaft saddle 8, and a horizontal shaft column 9 is fixed on the horizontal shaft saddle, and the horizontal shaft column The horizontal spindle box 10 and the horizontal spindle 49 are connected by a screw driving device, and a horizontal spindle tool magazine 11 is fixed on one side of the horizontal spindle base; A rotary table 48 is fixed, and the longitudinal table 12 and the rotary table 48 are all connected to an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com