Integrated main skid device of mechanical cleaning system for large-scale oil storage tank

A technology for mechanical cleaning and oil storage tanks, which is applied in the fields of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of poor safety and environmental protection, high power consumption of boosting scheme, and weak suction ability. , to achieve the effect of easy operation and management, improved safety and environmental protection, safety monitoring and optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

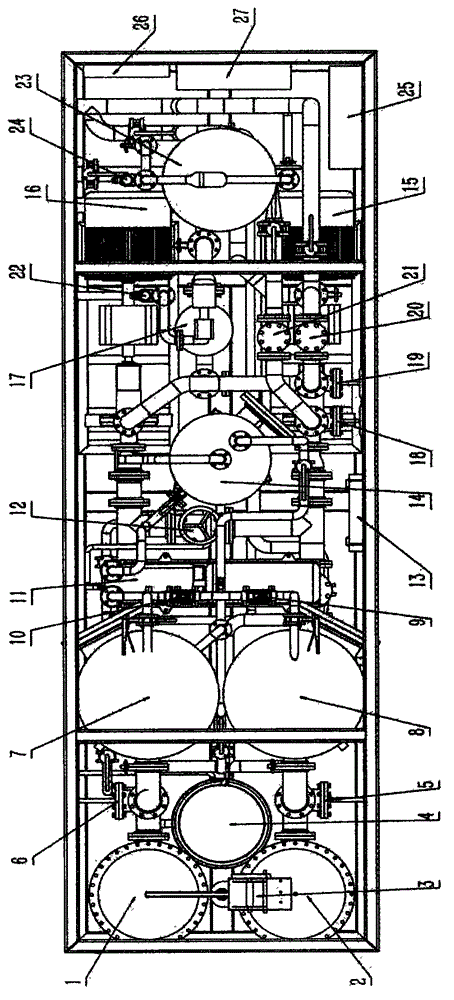

[0032] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples, but the examples cited are not intended to limit the present invention.

[0033] Such as figure 1 As shown, the embodiment of the present invention includes a negative pressure filter, a vacuum tank, a centrifugal pump, a vacuum pump 11, a gas-liquid separation tank 14, a positive pressure filter 17, an oil skimmer 23, a cleaner 4, a negative pressure filter and a vacuum One end of the tank is connected, the other end of the vacuum tank is connected to the centrifugal pump, the other end of the first centrifugal pump is connected to the negative pressure filter and the positive pressure filter, the vacuum tank is connected to the input end of the vacuum pump, and the output end of the vacuum pump is connected to the gas-liquid The separation tank 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com