Device for distributing material uniformly

A technology of uniform material plate and discharge port, applied in the directions of loading/unloading, transportation and packaging, conveyor, etc., can solve the problems of sheet running, uneven force, uneven thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

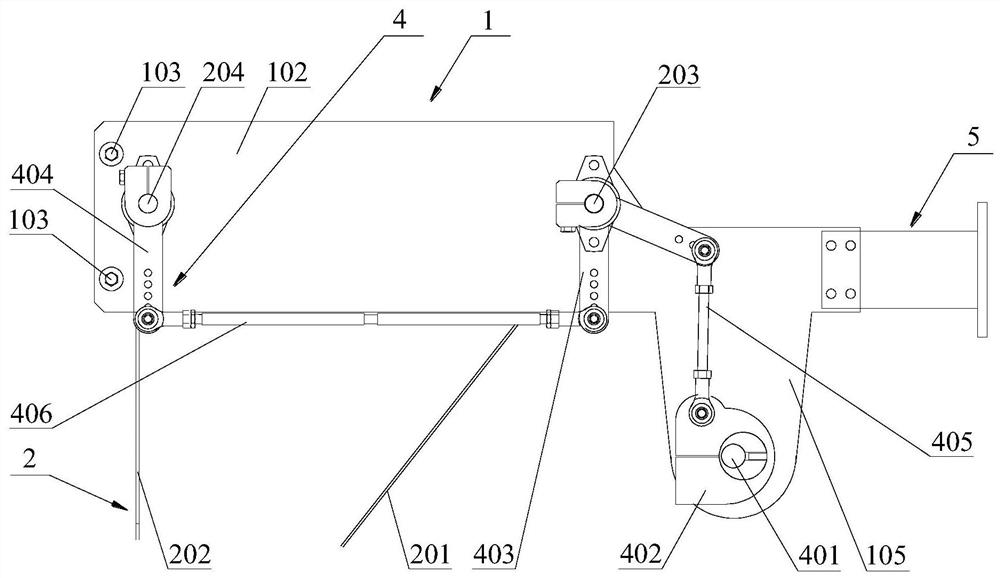

[0065] Combine the following Figure 1 to Figure 8 , a detailed description of a homogenizing device applied to the horizontal feeding system of a tobacco cutting machine proposed by this scheme. The assembly device described in this solution mainly includes: a supporting part 1 , a material equalizing part 2 , a driving part 3 and a linkage part 4 . Through the supporting part 1, the uniform material part 2, the linkage part 4 and the driving part 3 are arranged in the discharge port 6 of the vibrating conveyor above the vibrating conveyor, and at the same time, the supporting part 1 is fixed on other equipment and brackets by using the fixing part 5 Or on the wall. When the tobacco is conveyed to the discharge port 6 of the vibrating conveyor, the linkage part 4 transmits the power output by the drive part 3 to the uniform material part 2, and through the reciprocating swing of the uniform material part 2 on the support part 1, it will be transmitted to the feeding vibratio...

Embodiment 2

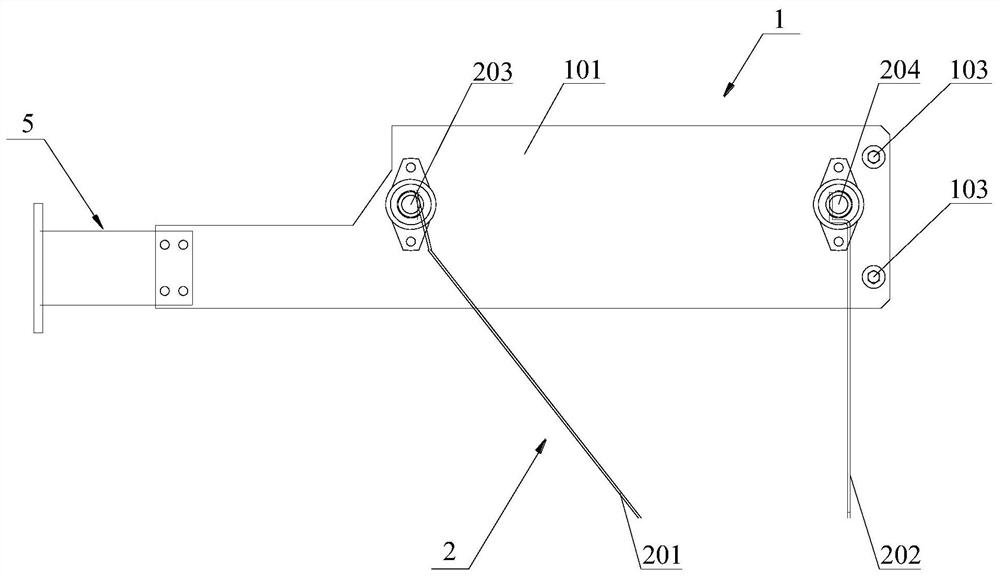

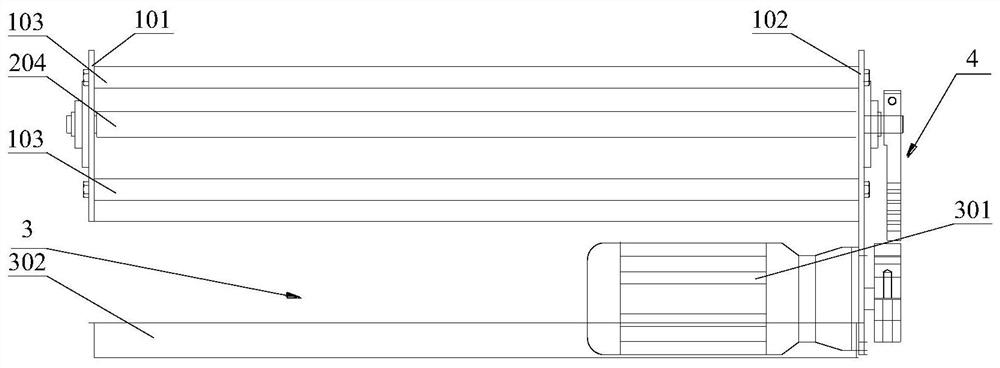

[0086] Combine the following Figure 9 to Figure 14 , to describe in detail another homogenizing device applied to the horizontal feeding system of the tobacco cutting machine proposed by this scheme. The assembly device described in this solution mainly includes: a supporting part 1 , a material equalizing part 2 , a driving part 3 and a linkage part 4 . The supporting part 1 is used as the discharge port of the tobacco vibrating conveyor. At the same time, the supporting part 1 can fix the uniform part 2, the linkage part 4 and the driving part 3. In addition, the rear side of the supporting part 1 can also be supported by the fixing part 5. Part 1 is fixed on other equipment, supports or walls. When the tobacco enters the supporting part 1, the linkage part 4 transmits the power output by the driving part 3 to the homogenizing part 2, and through the reciprocating swing of the homogenizing part 2 on the supporting part 1, the tobacco entering the supporting part 1 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com