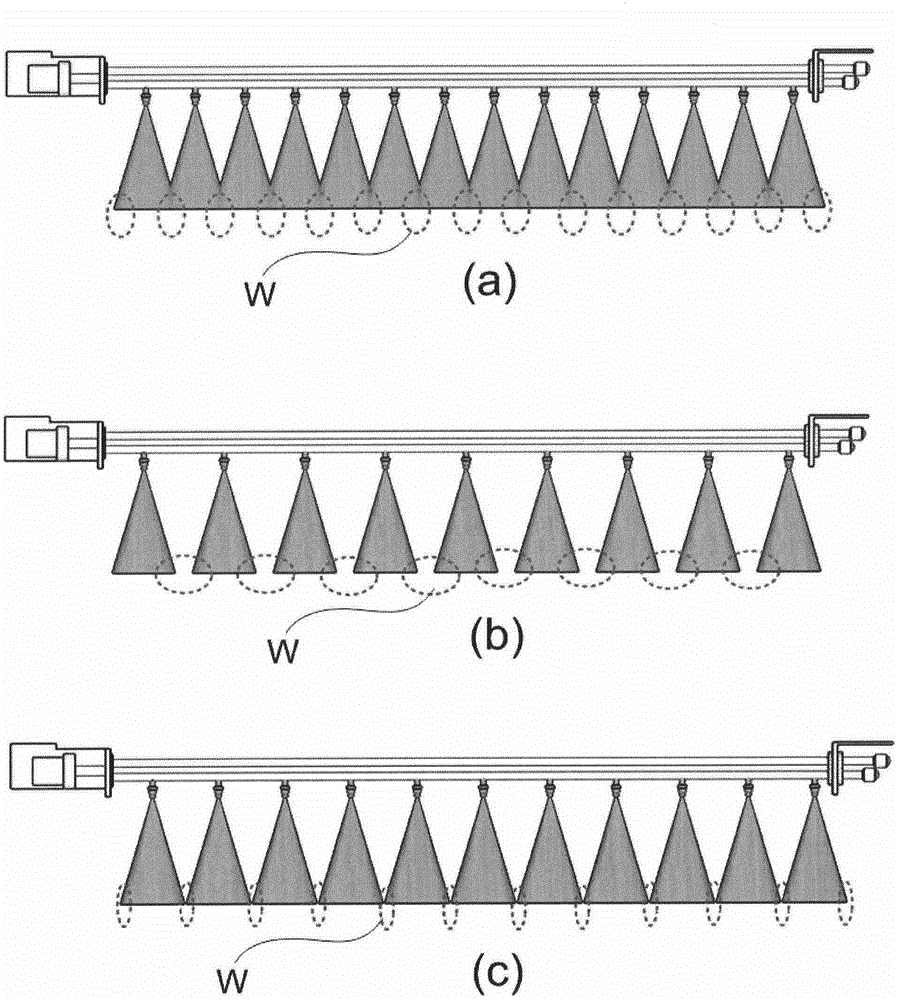

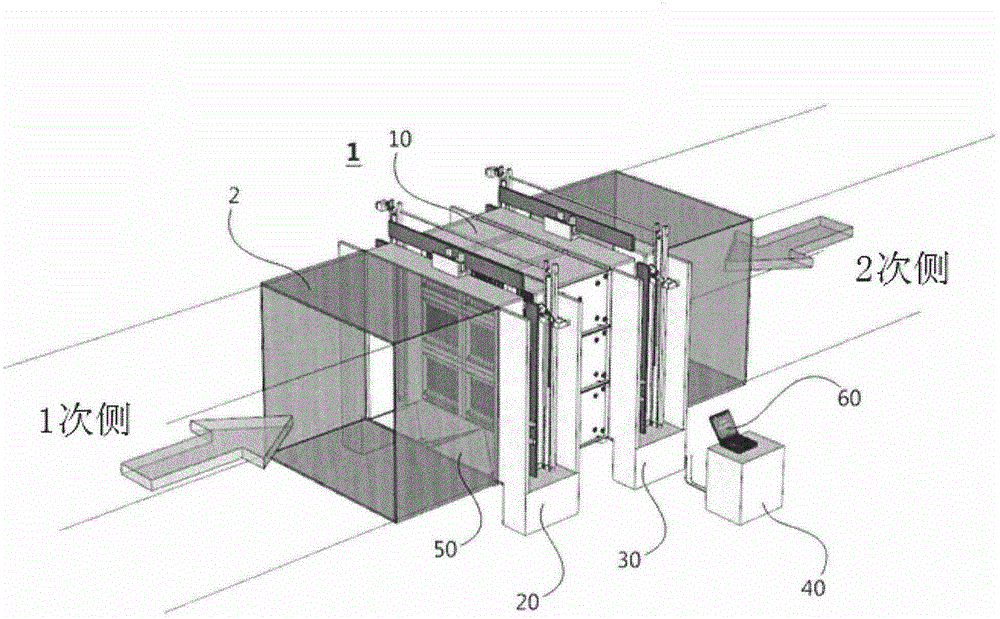

Bi-directional dust collection system

A technology of dust collection system and flow direction, which is applied in the field of cleaning devices to achieve the effects of easy assembly, easy maintenance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The following detailed description of the invention refers to illustrations of specific implementations of the invention. In order to allow practitioners to refer to and execute, these execution examples are explained in great detail. The various implementations of the invention, while different, are understood to be not necessarily mutually exclusive. For example, an implementation example of a specific image, structure, and characteristic described here may be embodied as a different implementation example within the technical idea and scope of the invention. In addition, the position or arrangement of individual constituent elements in each embodiment can be changed without departing from the technical idea and scope of the invention. Therefore, the purpose of the following detailed description is not intended to be limiting, and the scope of the invention includes all claims identical to the claims of the claims and the claims attached thereto. Similar reference s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap