Heat pipe boiler

A heat pipe and outer pot technology, applied in indirect heat exchangers, lighting and heating equipment, cooking utensils, etc., can solve the problems of fast heat conduction, small heat dissipation area, poor heat preservation performance, etc., and achieve large heat conduction and heat dissipation area, heat dissipation speed Fast, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

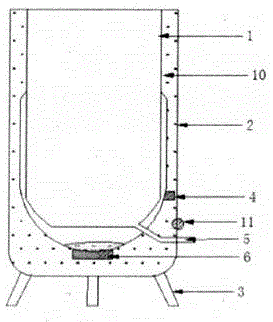

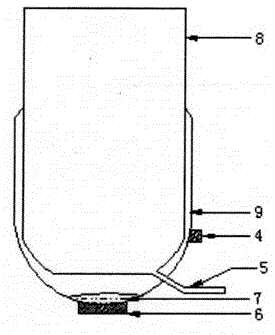

[0026] Such as figure 1 As shown: the heat pipe pot is composed of a sandwich pot body (1), a shell (2), an insulation layer (10), a control switch (11), a support (3), and a drainage device (5).

[0027] The shell (2) is wrapped on the outside of the sandwich pot body (1), and the bracket (3) is installed under the bottom of the shell (2).

[0028] 1. The distance between the shell (2) and the sandwiched pot body (1) is 30mm, and after the upper end of the sandwiched pot body (1) is sealed and welded with the shell (2), the bonding position is 0mm;

[0029] 2. The gap between the shell (2) and the sandwich pot body (1) is filled with the insulation layer (10) to keep it warm;

[0030] 3. The control switch (11) is installed on the outside of the casing (2), and the circuit in the control switch (11) is connected to the heating device (6) and the temperature control sensor (4) to work;

[0031] 4. The bottom of the sandwich pot body (1) is convex; the bottom of the shell (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com