Rotor core of brushless motor

A technology of rotor iron core and brushless motor, which is applied in the manufacture of motor generators, stator/rotor bodies, electric components, etc., which can solve the problem of affecting the heat dissipation and working performance of fans, low effective utilization of permanent magnets, and built-in rotors. Problems such as large magnetic flux leakage of punching sheets, to achieve excellent magnetic isolation effect, reduce magnetic flux leakage phenomenon, and weaken the effect of local magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

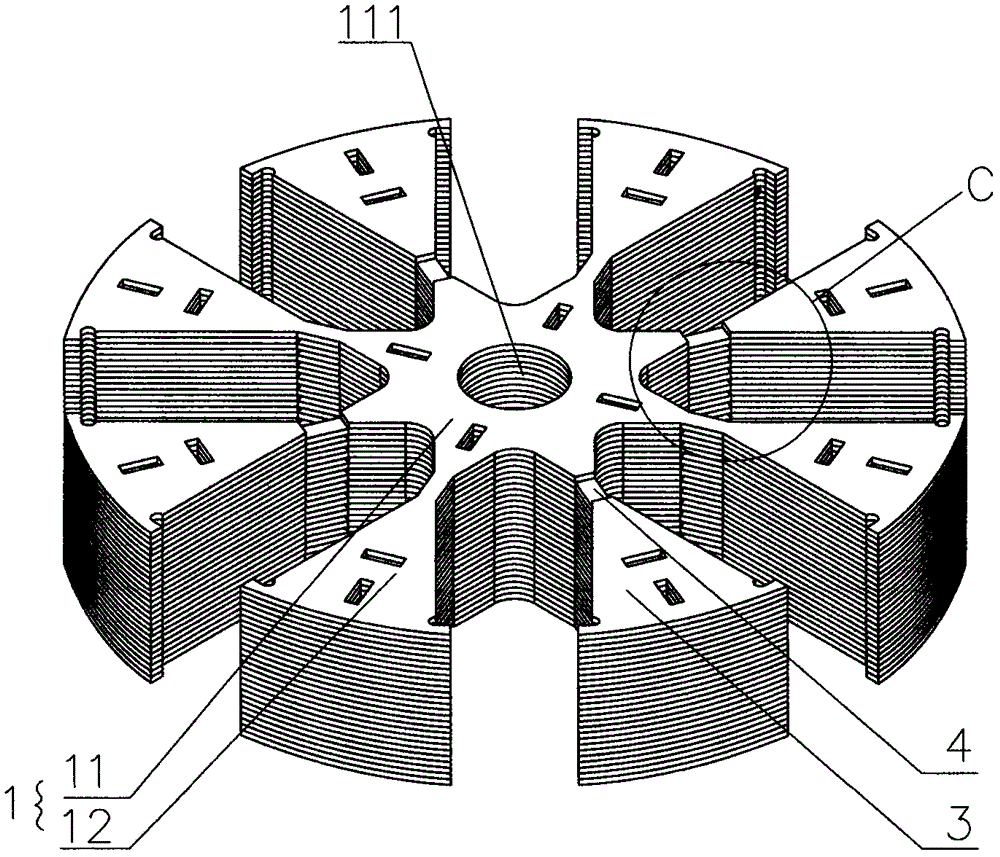

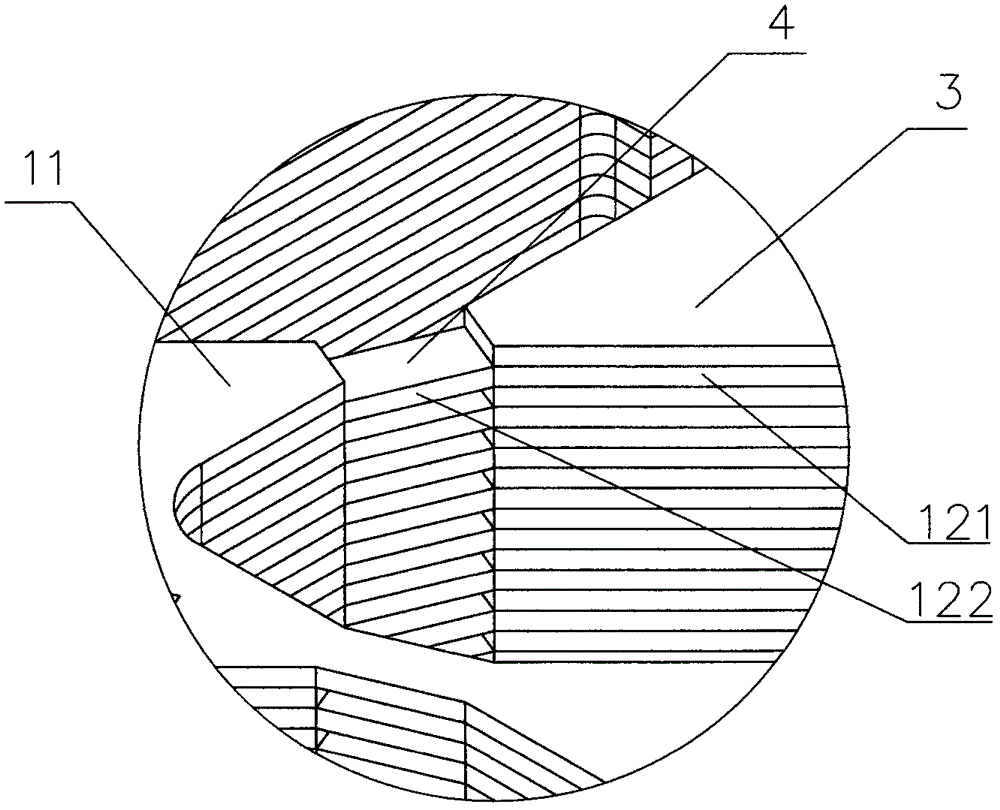

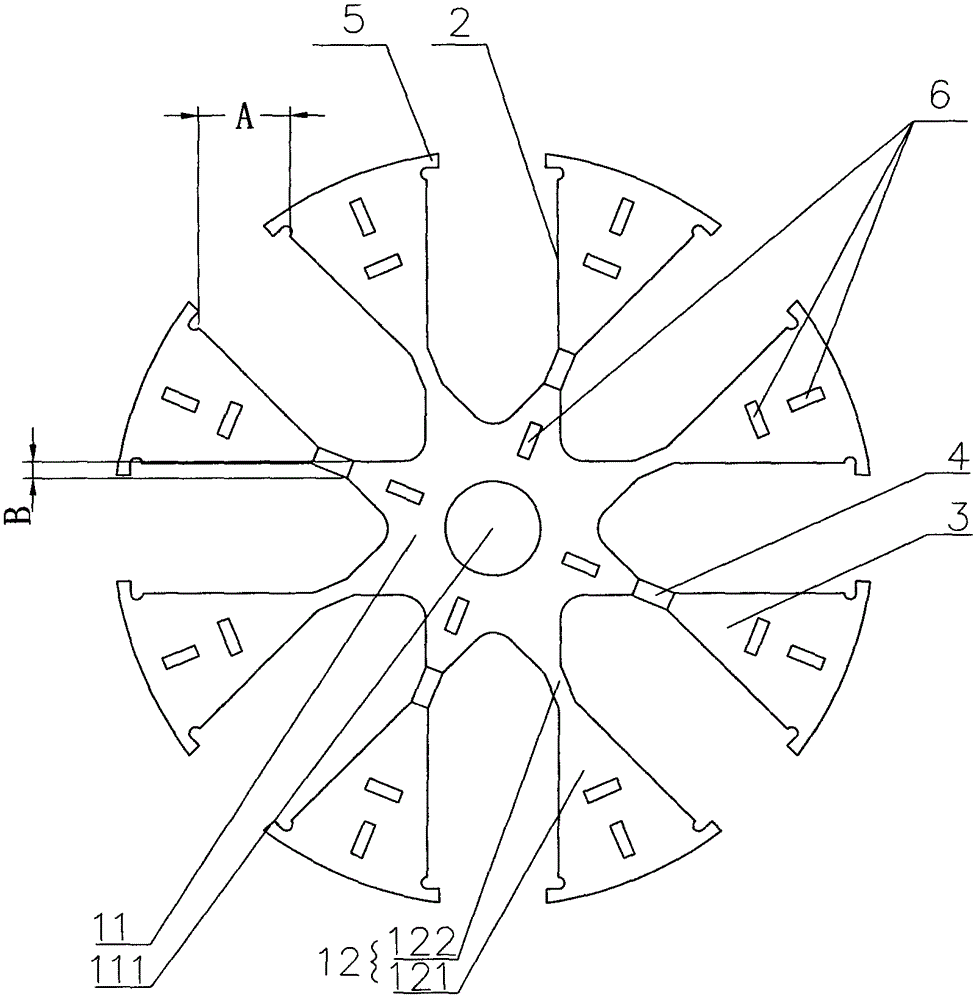

[0021] refer to figure 1 , figure 2 and image 3 , a brushless motor rotor core shown, including a core body, the core body includes a laminated rotor punch 1, the rotor punch 1 includes a main body 11, along the circumferential direction of the main body 11 uniformly spaced iron chips 12 and The block 3 located between the adjacent iron chips 12, the center of the main body 11 is provided with a shaft hole 111 for installing the rotating shaft, the block 3 is located in the middle of the adjacent iron chips 12, and the formed between the block 3 and the iron chips 12 There is a magnetic tile groove 2, which is used to install magnets, a broken bridge 4 is formed at a certain distance between the block 3 and the main body 11, and in the adjacent rotor punch 1, the lower rotor punch 1 has an upper iron chip 12 It is located directly below the piece 3 on the upper rotor punching sheet 1. The piece 3 is attached to the iron chip 12, and the magnet is interference-connected bet...

Embodiment 2

[0028] A brushless motor rotor iron core, comprising an iron core body, the iron core body includes laminated rotor punches, and the rotor punches include a main body, iron chips arranged at uniform intervals along the circumferential direction of the main body, and splices between adjacent iron chips. The center of the main body is provided with a shaft hole for installing the rotating shaft. The block is located in the middle of the adjacent iron chip. A magnetic tile groove is formed between the block and the iron chip. The magnetic tile groove is used to install the magnet, the block and the main body. Broken bridges are formed at intervals, and among the adjacent rotor punches, the iron chips on the lower rotor punch are located directly below the pieces on the upper rotor punch, and the magnets are positioned between the iron chips and the pieces. The iron core body and the connecting bridge connected between the iron core body and the main body. The difference between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com