Fully-automatic feeding and discharging equipment for printing photovoltaic solar cell silicon wafers

A technology of solar cells and cells, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as wasting time, low cell efficiency, and reduced production capacity, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

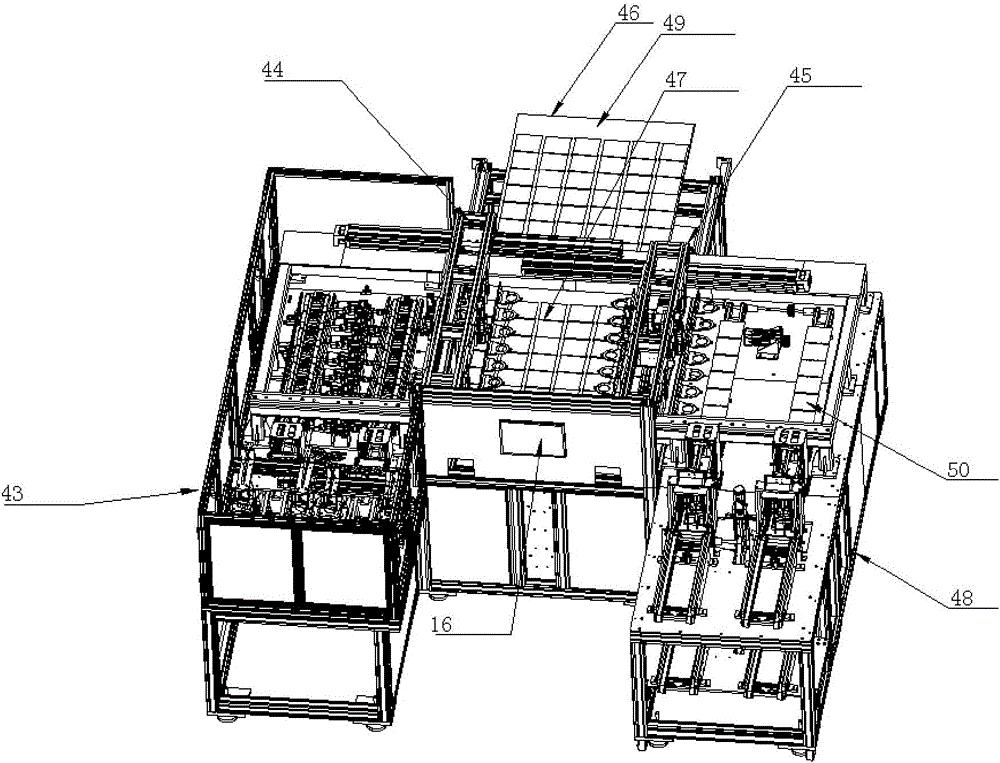

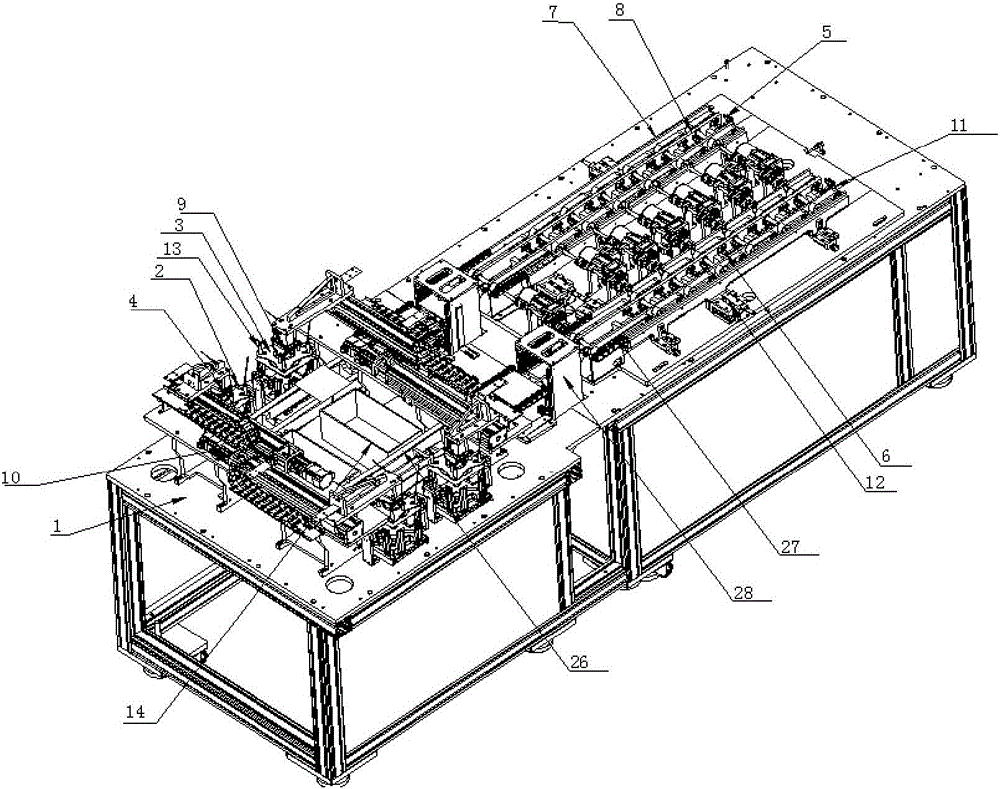

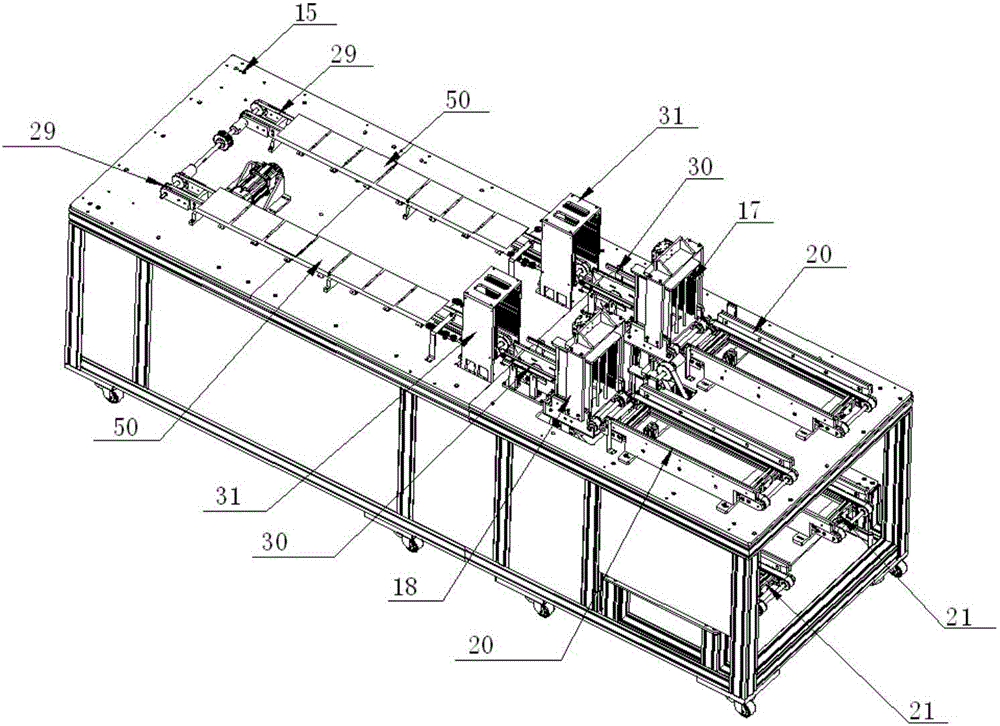

[0026] Embodiment: A fully automatic photovoltaic solar cell silicon wafer printing and loading and unloading equipment, including a loading module 43, a feeding and conveying module 44, a blanking and conveying module 45, a graphite frame conveying module 46, a lifting module 47, The unloading module 48 and the control system 16, the feeding module 43 includes the battery sheet holder 2, the feeding conveying mechanism and the feeding positioning mechanism, and the feeding conveying mechanism can convey the battery sheets 50 in the battery sheet holder 2 one by one At the loading and positioning mechanism, the loading and positioning mechanism can stop and position the cells arranged sequentially on it. The unloading module 48 includes the cell flower basket positioning mechanism 18, the cell discharge conveying device and the cell holder 2 cells The flower basket discharge conveying device 20, the cell flower basket positioning mechanism 18 can fix and position the empty batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com