Optical cable with special-shaped optical fiber loose sleeves

A technology of optical fiber loose and loose tubes, which is applied in the field of optical cables and special-shaped optical fiber loose tubes. It can solve the problems of identification, inconvenient construction, and difficult identification, and achieve the effects of convenient construction and identification, easy identification, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

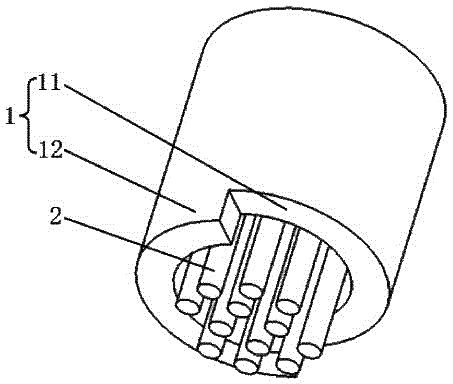

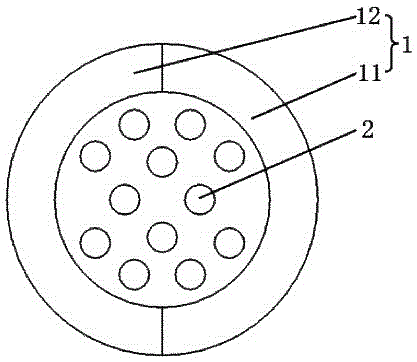

[0041] Please see figure 1 with figure 2 , Shaped optical fiber loose tube, including 12 optical fibers 2, loose tube 1 covering the optical fiber; characterized in that the loose tube is composed of a first part 11 and a second part 12; the loose tube is The first part and the second part are bonded together, or the first part and the second part of the loose tube are formed integrally; the inside and the outside of the loose tube are both cylindrical surfaces.

[0042] The first part and the second part have different colors.

Embodiment 2

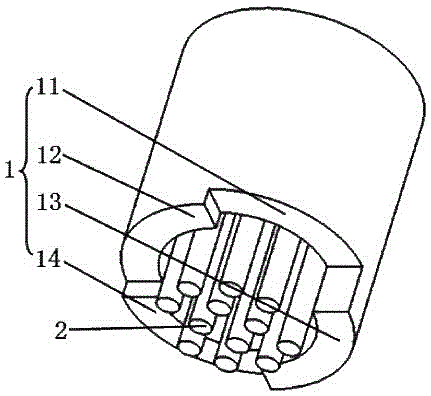

[0044] Please see image 3 with Figure 4 , Shaped optical fiber loose tube, including 12 optical fibers 2, loose tube 1 covering the optical fibers; characterized in that the loose tube is composed of a first part 11, a second part 12, a third part 13 and The fourth part 14 is composed; the loose tube is formed by bonding the first part, the second part, the third part, and the fourth part end to end or the first part, the second part, the third part and the fourth part in the loose tube The part is integrally formed; the inside and outside of the loose tube are cylindrical.

[0045] Further, in this embodiment, the loose tube of the special-shaped optical fiber includes a plurality of optical fibers and a loose tube covering the optical fibers; it is characterized in that the loose tube is composed of other parts; the loose tube It is formed by bonding multiple parts end-to-end or multiple parts of the loose tube are integrally formed; the inside and outside of the loose tube a...

Embodiment 3

[0049] Please see Figure 5 with Image 6 And refer to figure 1 with figure 2 , Optical cable, which includes a central strengthening member 3, a plurality of special-shaped optical fiber loose tube 1 described in the embodiment 1 twisted around the central strengthening member, the special-shaped optical fiber loose tube is covered with a protective layer 4, a protective layer The outside is extruded and covered with a sheath layer 5; there are multiple optical fibers 2 inside the loose tube of the shaped optical fiber; the loose tube is composed of a first part 11 and a second part 12; the loose tube is composed of a first part and a second part Partially bonded or the first part and the second part of the loose tube are integrally formed; the inside and outside of the loose tube are cylindrical.

[0050] The above-mentioned optical cable is characterized in that at least one of the plurality of special-shaped optical fiber loose tubes is replaced by a filling rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com