Storage stack test tool and test method thereof

A technology for testing tooling and testing methods, applied to measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve inaccurate test results, evaluation of test result deviations, parameter measurement and whether packaging protection design is reasonable and inconvenient and other problems, to achieve the effects of simple structure, improved packaging design, and little impact on stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

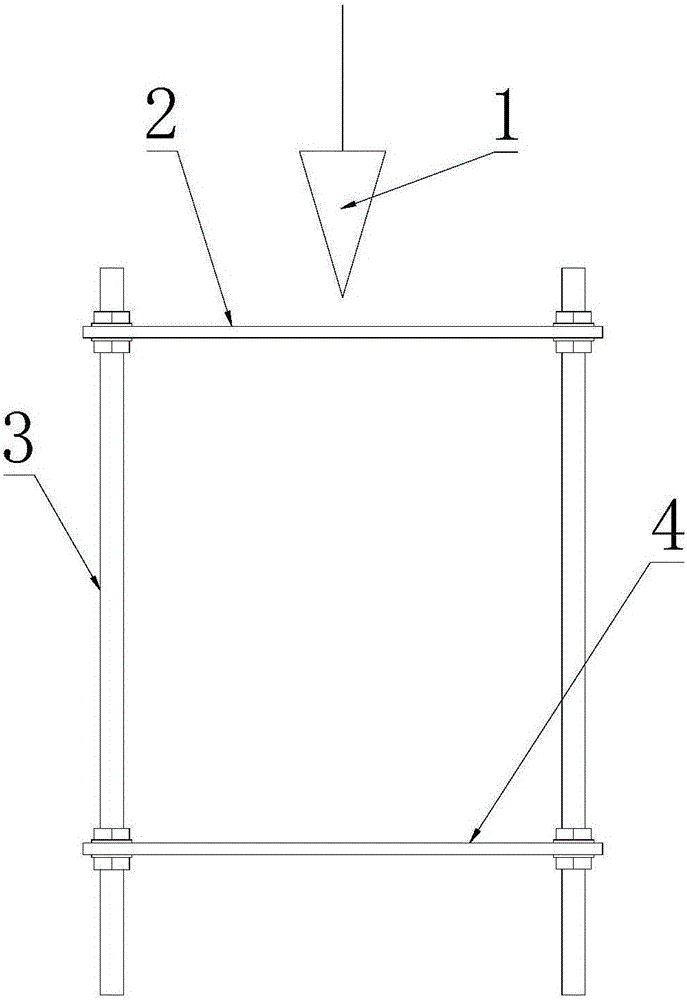

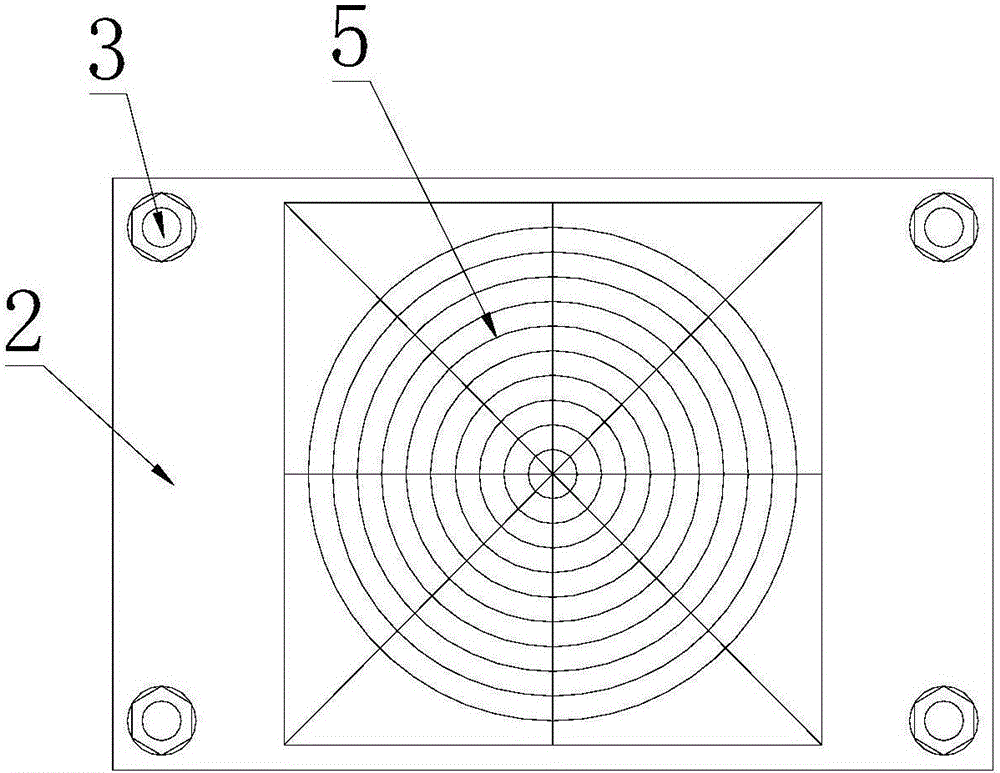

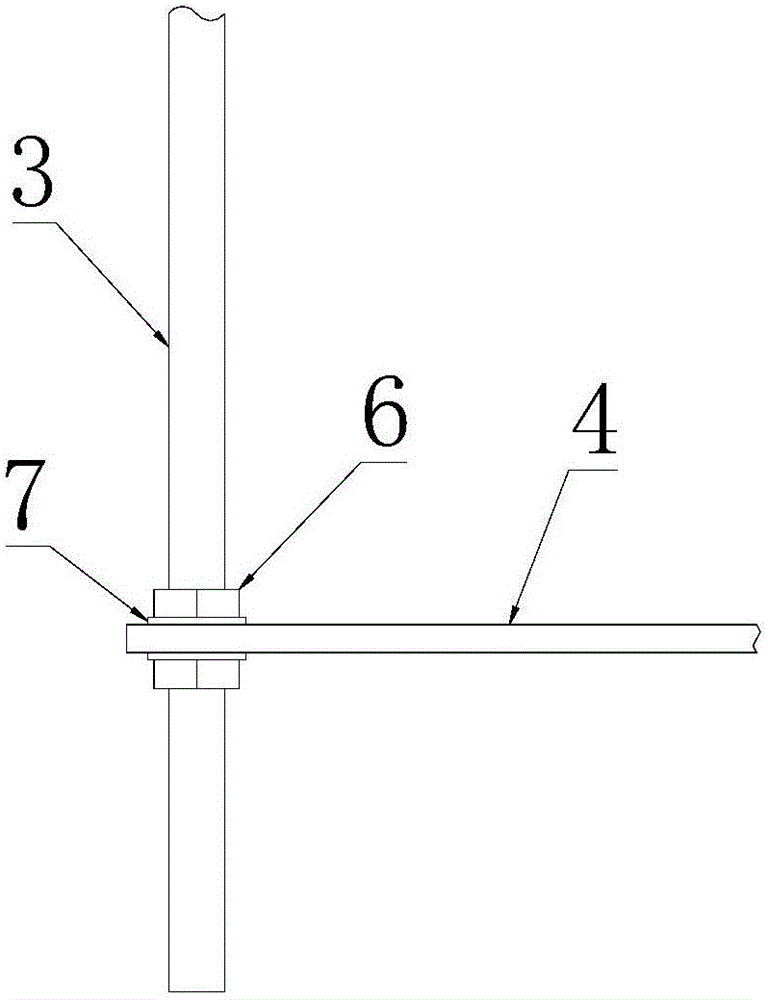

[0035] Such as Figure 1 to Figure 4 As shown, the present invention discloses a storage stacking test tool, including: a reference unit arranged beside the stacking, a follower unit arranged above the reference unit and capable of reflecting the displacement of the topmost items in the stacking, the The offset generated by the follower unit relative to the reference unit is used to reflect the offset and offset direction of the stacking relative to the initial storage state. By setting the follow-up unit to simulate the displacement of the top-level items in the stack, and then measuring the offset generated by the follow-up unit relative to the reference unit after storage, the horizontal offset and height drop generated by the stack during storage can be obtained. Combining with parameters such as the height of stacking, the deflection angle of stacking is further obtained. The follow-up unit simulates the displacement of the top stacked items, and the obtained parameters ...

Embodiment 2

[0040] This embodiment is basically the same as the first embodiment, the only difference is that a fixed plate 4 is connected between the several adjusting rods 3 , and the fixed plate 4 and the horizontal plate 2 are respectively welded to the several adjusting rods 3 . That is, the welding connection is used to replace the clamping and fixing of the bolts 6 and gaskets 7 in the first embodiment. This structure is more stable, and there is no need to worry about the displacement of the horizontal plate 2 during the test, but its adjustability is too poor. The height cannot be adjusted, and it can only be used for stacking tests within a certain height range.

Embodiment 3

[0042] This embodiment is basically the same as the first embodiment, the only difference is that, on the basis of the horizontal plate 2 , the reference unit further includes a hydraulic device with a scale for adjusting the height of the horizontal plate 2 . That is, the height of the horizontal plate 2 from the ground is accurately determined by adjusting the degree of expansion and contraction of the hydraulic device in combination with the scale; the operation is simple and the data is accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com