Silk thread tension measuring device

A measuring device and tension technology, applied in the direction of tension measurement, etc., can solve the problems of high-speed, digital, flexible, complex structure, inconvenient use and other problems in the textile industry, and achieve easy maintenance and replacement, high measurement accuracy and convenient use reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

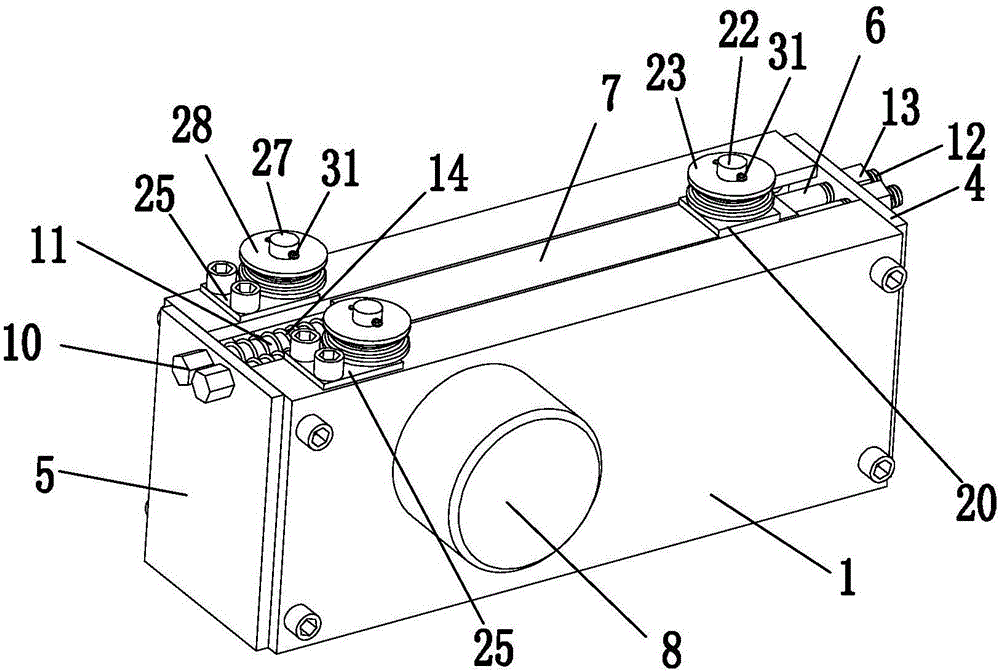

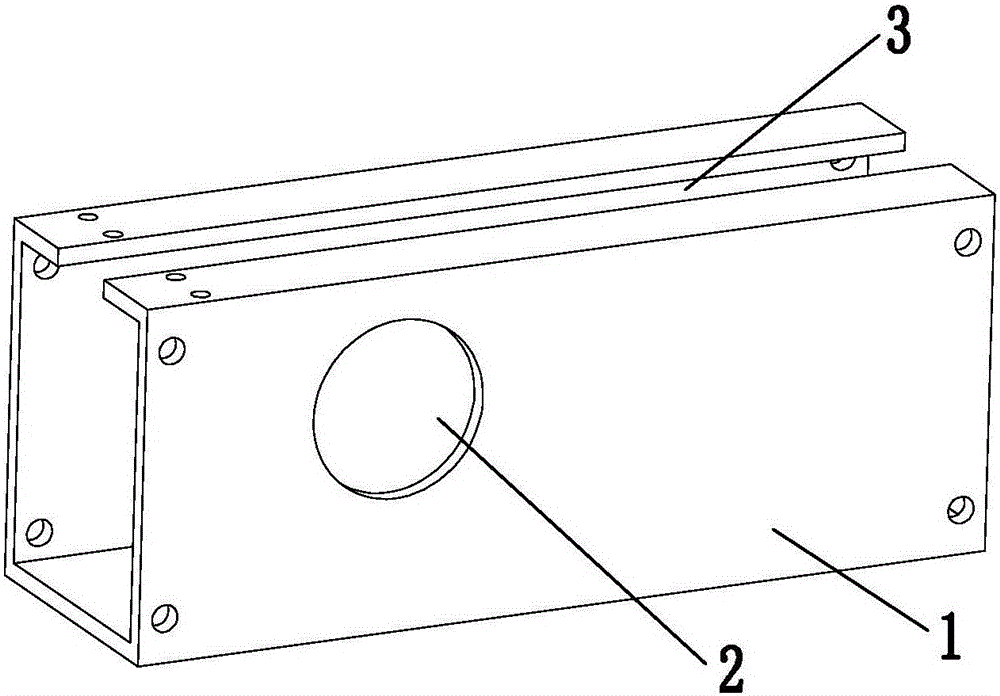

[0019] A kind of wire tension measuring device of the present embodiment, such as figure 1 As shown in -6, it includes a hollow casing 1; the two ends of the hollow casing 1 are not sealed, and a potentiometer mounting hole 2 is opened on one side of the hollow casing 1, and a potentiometer mounting hole 2 is opened on the top surface of the hollow casing 1. There are rack and guide rod installation openings 3; one end of the hollow shell 1 is installed with a front baffle plate 4 through screws, and the other end of the hollow shell 1 is equipped with a rear baffle plate 5 through screws; Two guide rods 6 are erected at the upper middle position between the plate 4 and the rear baffle 5, and the two guide rods 6 are located at the rack and guide rod installation opening 3; the two guide rods 6 A rack device 7 is set on the upper sleeve, so that the rack device 7 is also located at the rack and guide rod installation port 3; the rack device 7 is equipped with a measuring guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com