Distributed optical fiber monitoring calibration and test method and device for soil deformation

A technology of distributed optical fiber and soil deformation, applied in measurement devices, optical devices, instruments, etc., can solve the problems of restricting popularization and application, interaction mechanism between soil and strain sensing fiber, and coordinated deformation problems have not been fully understood , the reliability uncertainty of optical fiber monitoring results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

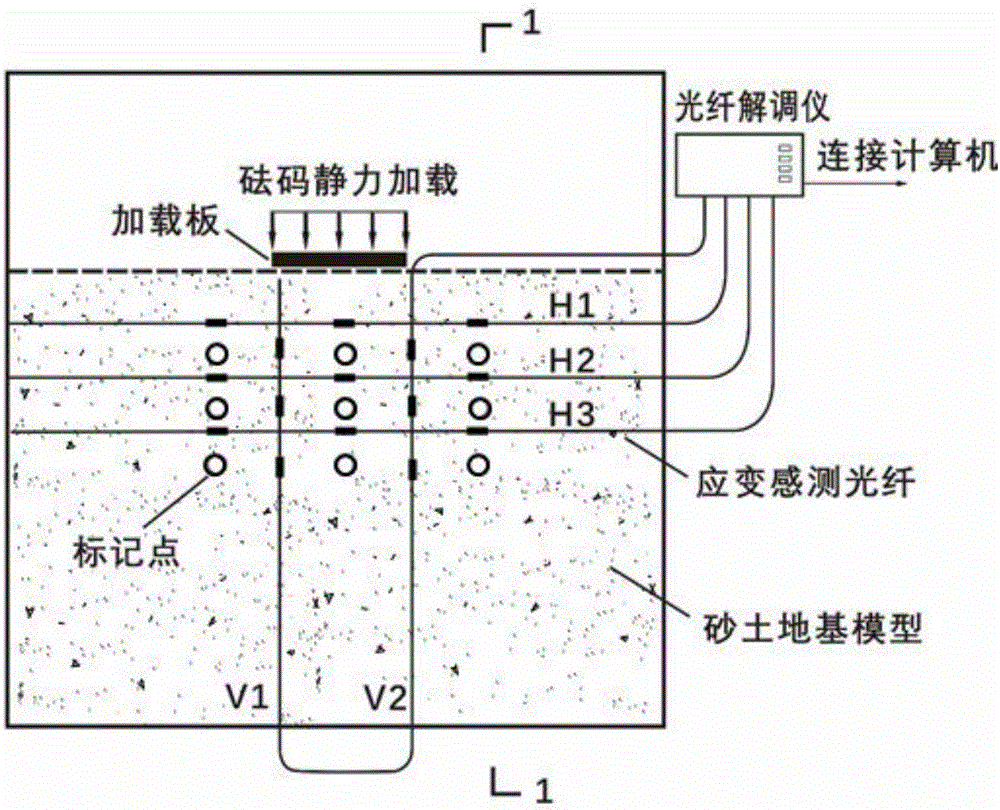

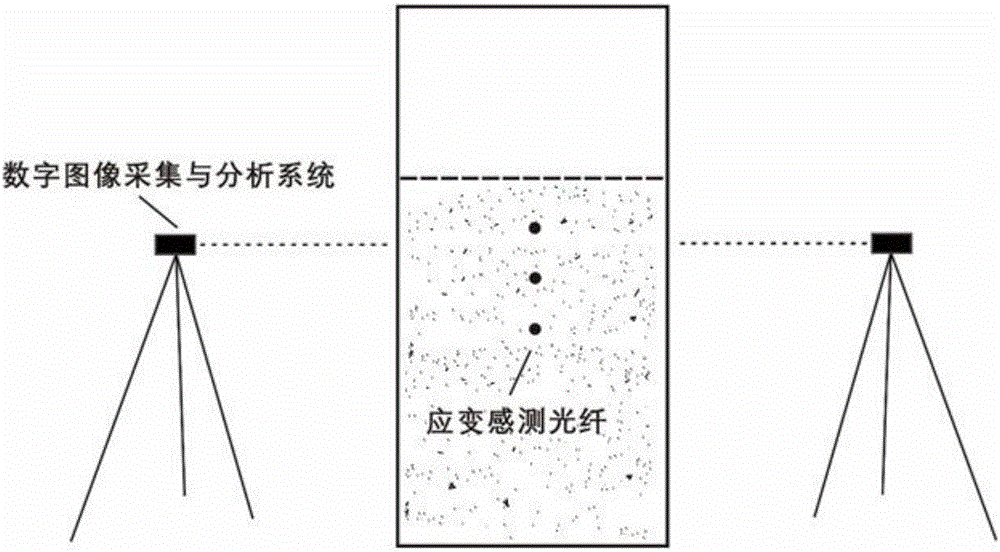

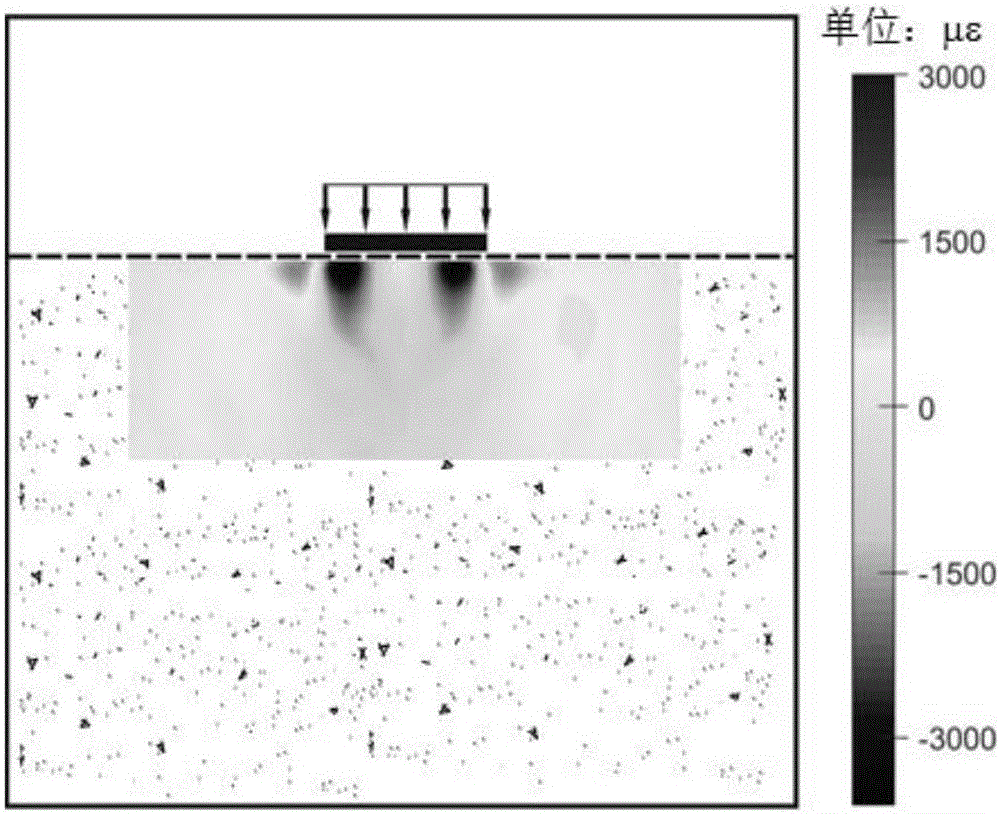

[0035] Such as figure 1 and figure 2 Shown, a soil deformation optical fiber monitoring calibration and test device, it includes calibration and test main box, strain sensing optical fiber, optical fiber demodulator, digital image acquisition and analysis device; the front and rear sides of the calibration and test main box It is a transparent rigid board, and the other two side boards are rigid boards, and the inside is filled with layered and compacted soil; the strain sensing optical fiber is laid horizontally and / or vertically in the soil segment by section; the optical fiber The demodulator is connected to the strain sensing optical fiber and collects strain data inside the soil; the digital image collection and analysis device is used to measure the displacement and strain of the soil in contact with the front and rear transparent rigid plates.

[0036] The two rigid side plates of the calibration and test main box have a number of small holes for passing through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com