Single-sliding-vane rotary displacement pump

A technology of rotary and volumetric pumps, which is applied in the direction of rotary piston pumps, rotary piston machines, rotary piston/swing piston pump components, etc. It can solve the problems of inability to form a sealed state, cumbersome manufacturing and processing, and affect the sealing performance, etc. problems, to achieve the effect of good sealing, wide range of uses and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

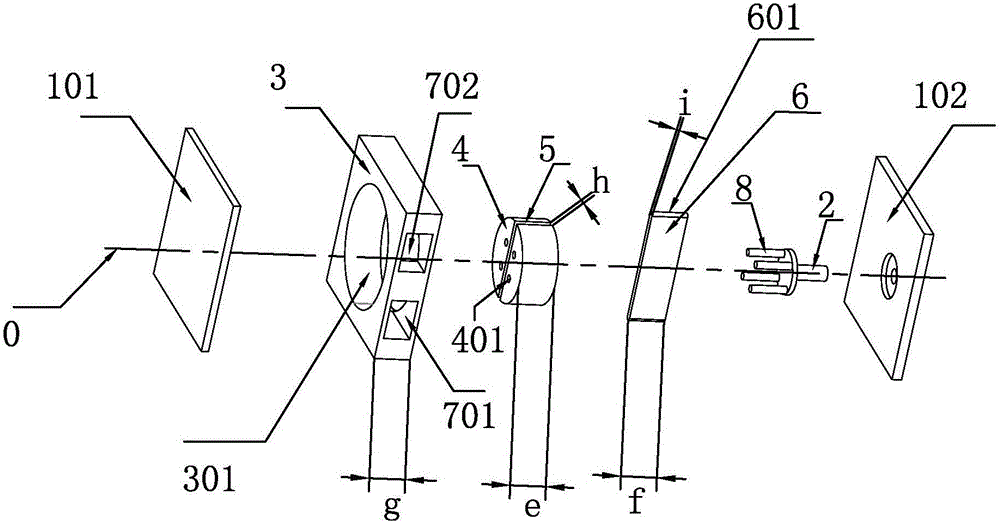

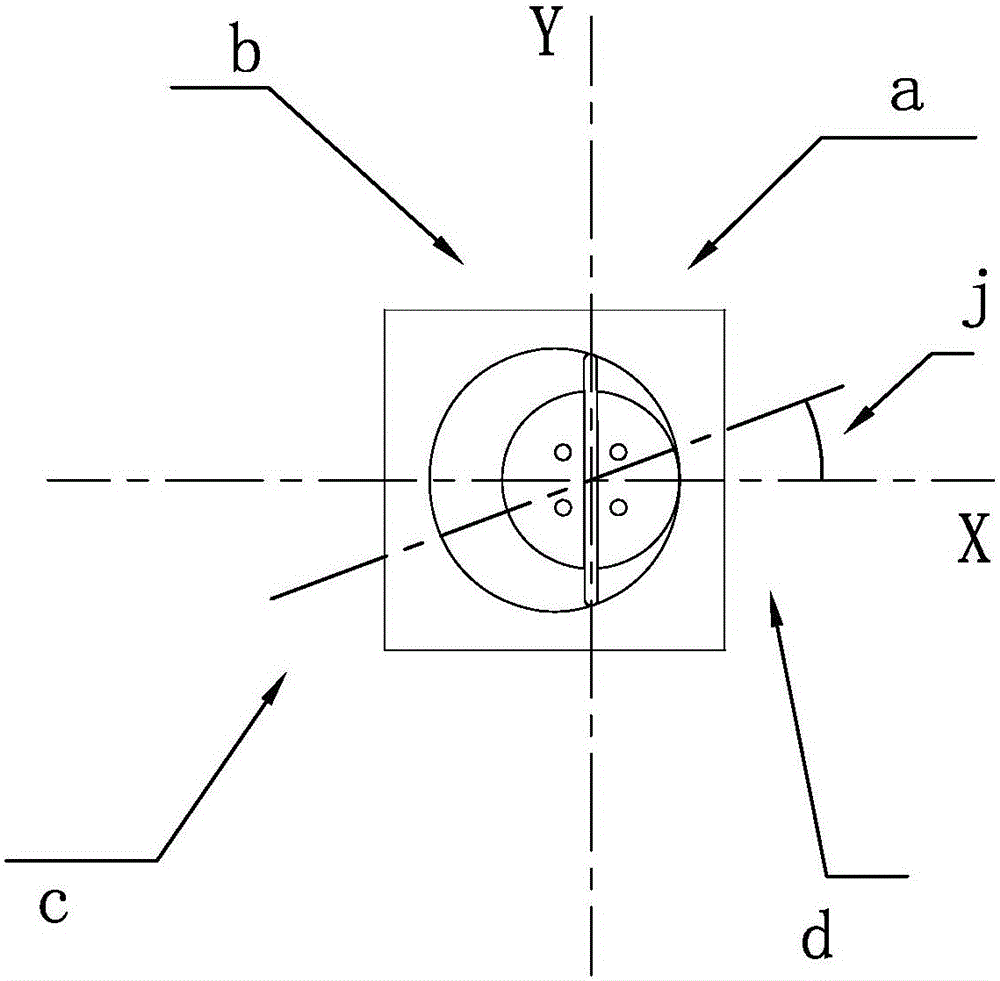

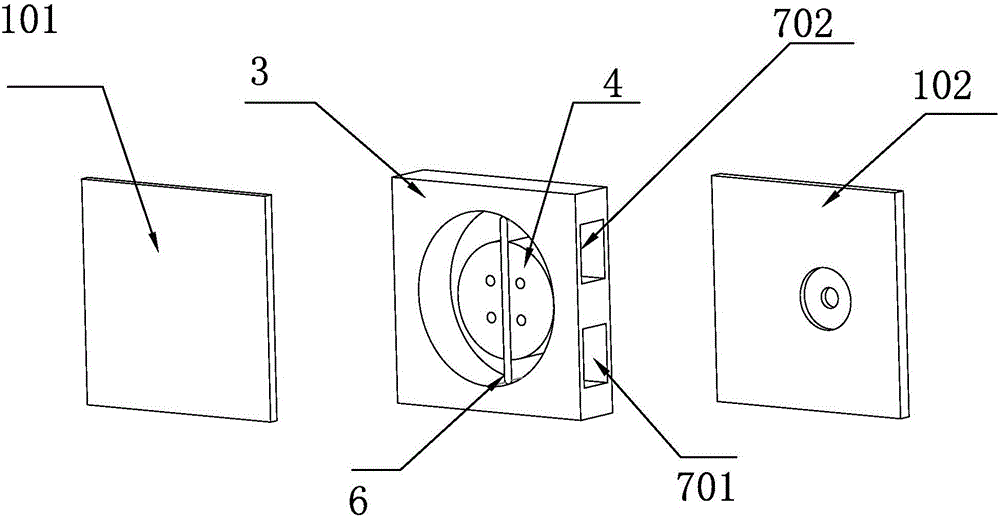

[0018] See attached figure 1 to attach image 3 , the present invention discloses a single vane rotary volumetric pump, a single vane rotary volumetric pump, comprising a front cavity splint 101, a rear cavity splint 102, a power shaft 2, a stator 3, a rotor 4, and a slide vane 6 , the feed port 701 and the discharge port 702, the front chamber splint 101 and the rear chamber splint 102 are respectively installed on the front and rear sides of the 3 stator, for sealing the stator 3; the axis of the power shaft 2 is the rotation axis 0; The section curve of the stator cavity 301 is a closed curve with a predetermined shape, and the section of the stator cavity 301 is perpendicular to the axis of rotation 0; Cut, the rotor 4 is cylindrical as a whole, the rotation axis 0 passes through the upper and lower centers of the rotor 4, the rotor 4 rotates around the rotation axis 0, and the rotor 4 is provided with a radially through slide slot 5 on the surface where the rotation axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com