Backwater once-through water turbine

A type of water turbine and water turbine technology, applied in the field of water conservancy power generation devices, can solve the problems of low power, waste water, affect production, etc., and achieve the effect of increasing storage capacity and pressure, and not easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

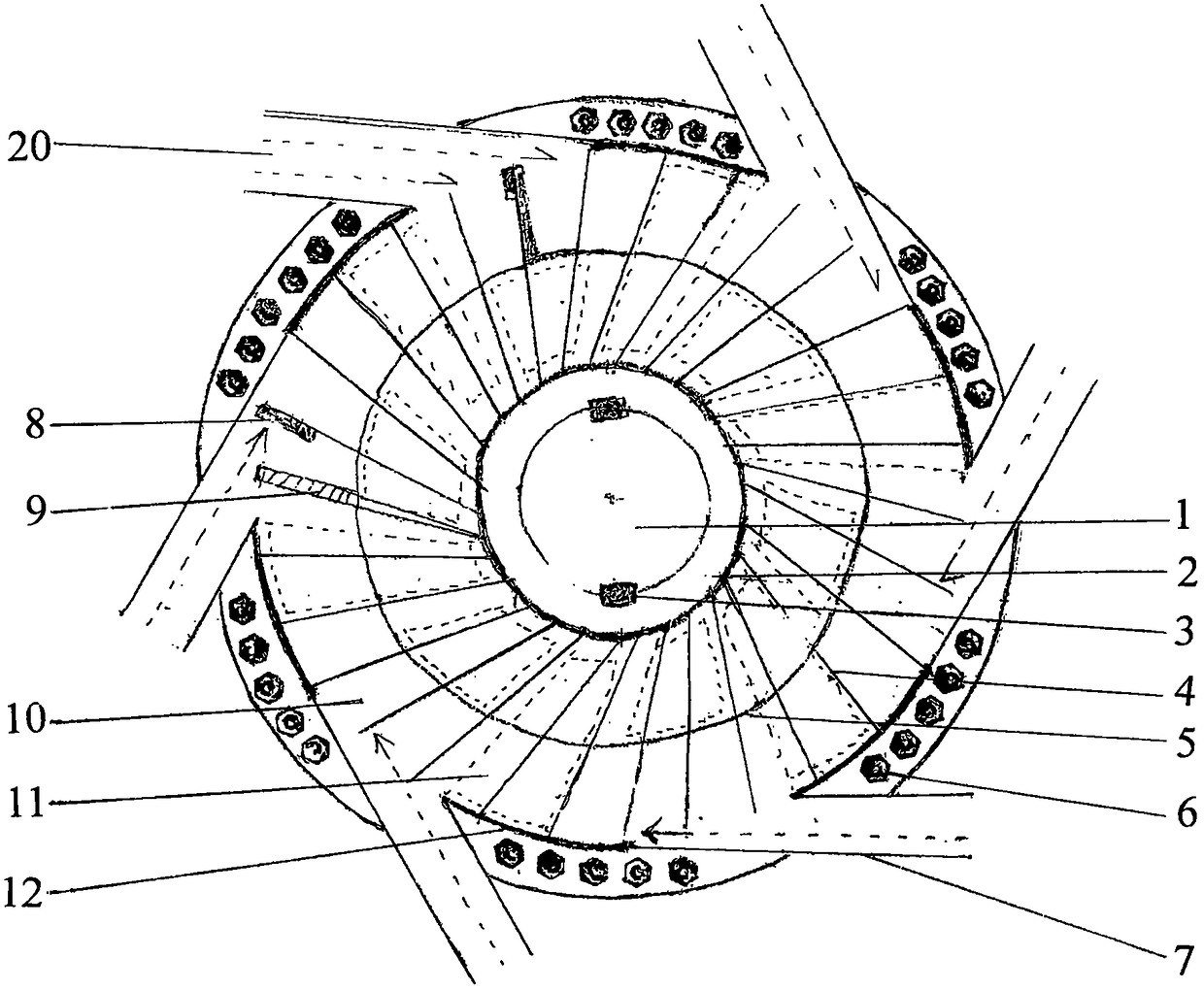

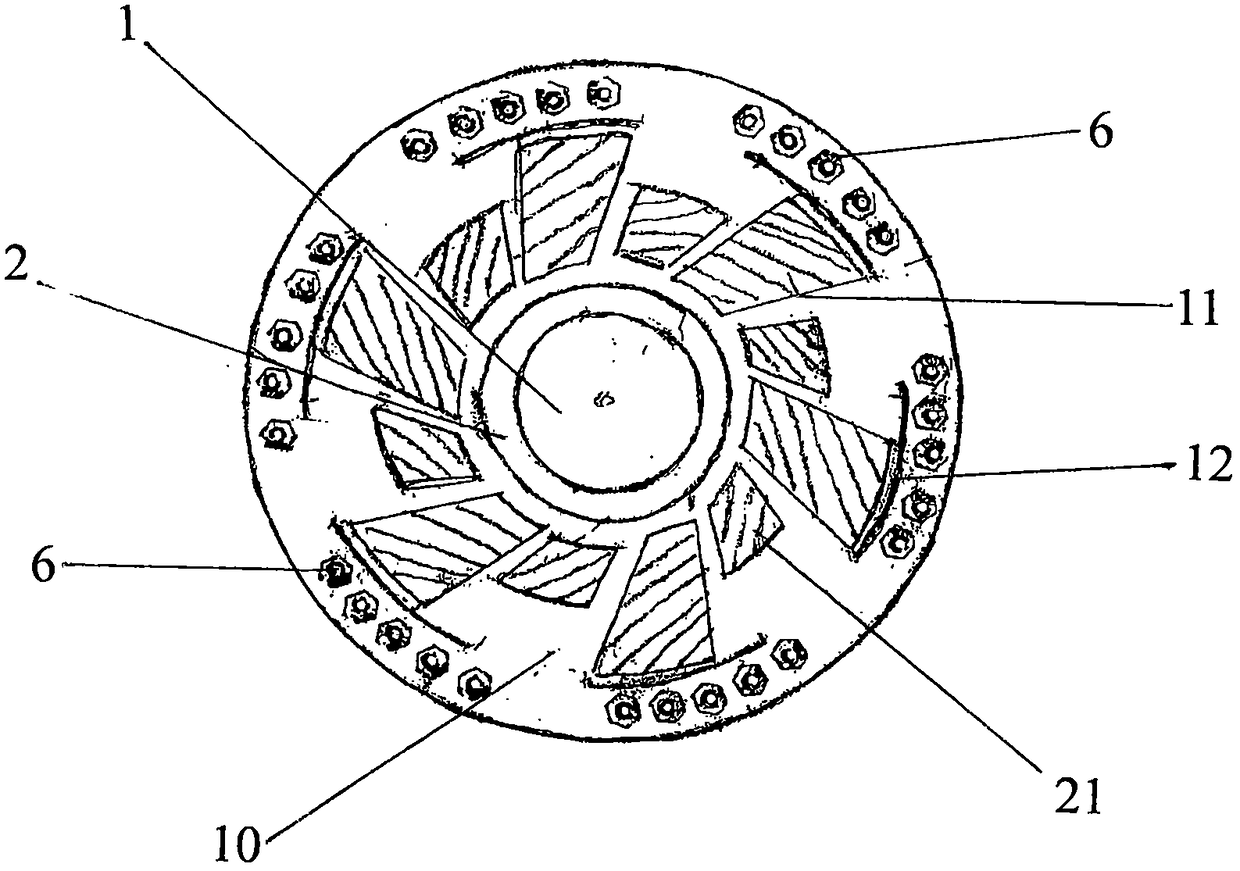

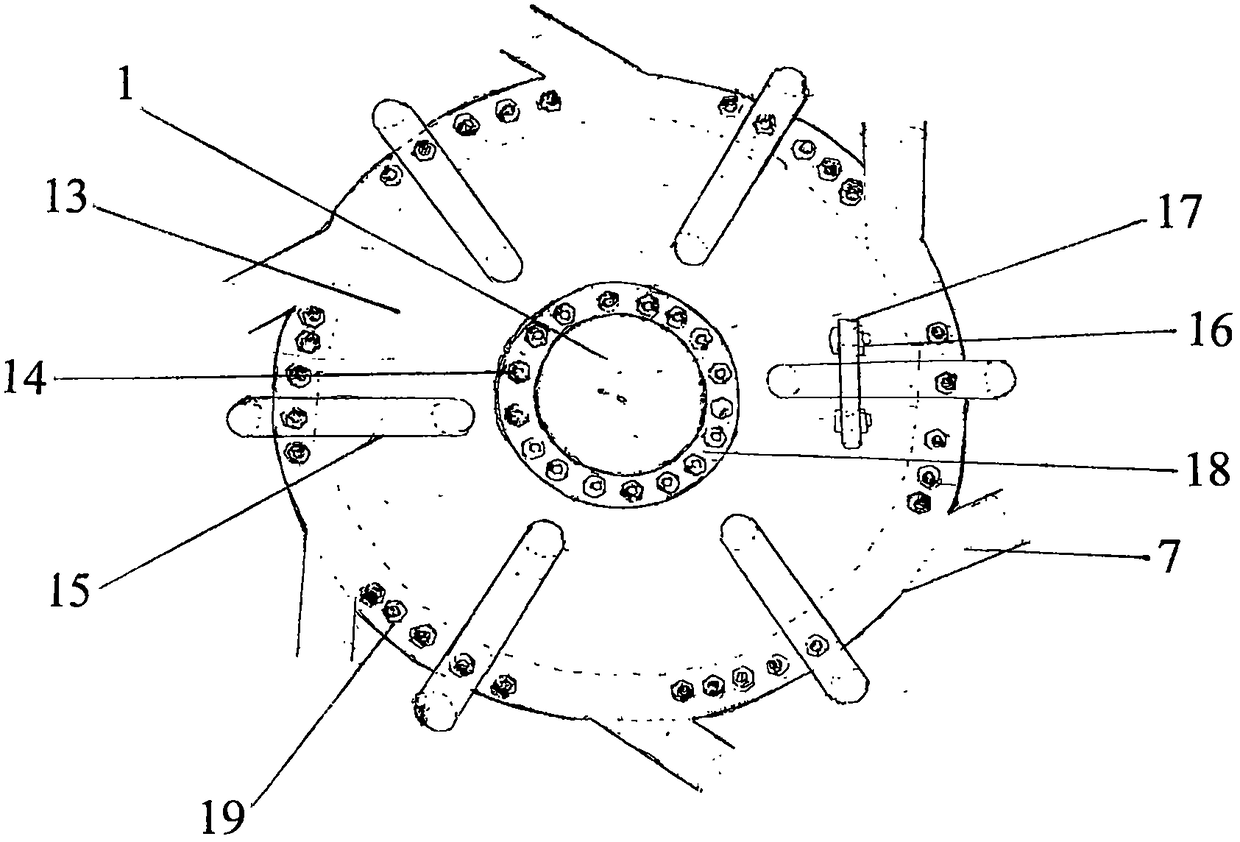

[0017] A backwater flow-through water turbine, which is characterized in that the bottom plate 10 of the circular turbine is fixed on the bottom ring with anchor bolts 6, the upper part of the cylindrical turbine main shaft 1 is connected with the generator, and the lower outer ring of the cylindrical turbine main shaft 1 is connected with a connecting key 3 It is fixedly connected to the center sleeve 2 of the turbine. The top plate 13 of the circular turbine and the bottom plate 10 of the circular turbine are fixedly connected to the outer ring by 6 arc rectangular turbine outer ring vertical walls 12, and the 6 arc rectangular hydraulic turbine outer ring vertical walls 12 There are 6 square water-conducting pipes 7 between the turbine bottom plate 10 and the turbine top plate 13, and there are no less than 30 turbine blades 4 evenly distributed on the outer ring of the turbine center sleeve 2. The straight passage of the runner can increase the turbine blades 4 and The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com