Self-cleaning barrel and washing machine employing same

A self-cleaning and washing machine technology, applied in the field of washing machines, can solve problems such as poor self-cleaning effect, and achieve the effect of increasing cleaning frequency and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

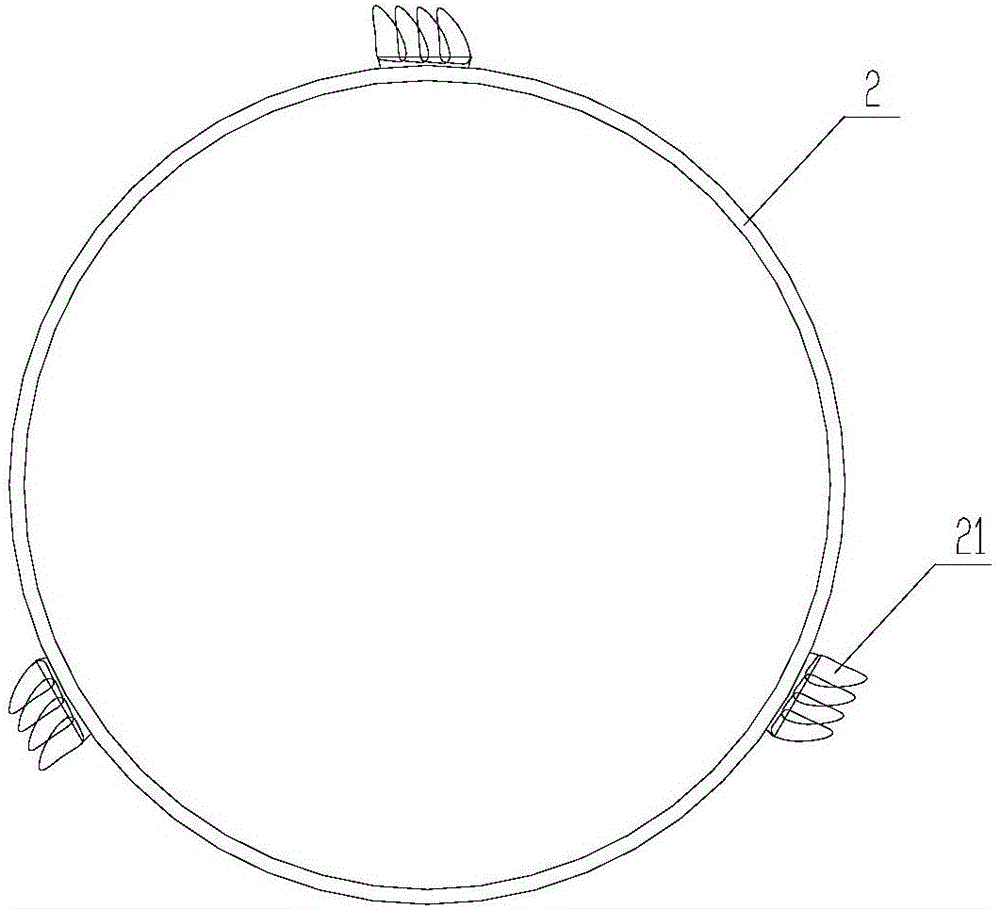

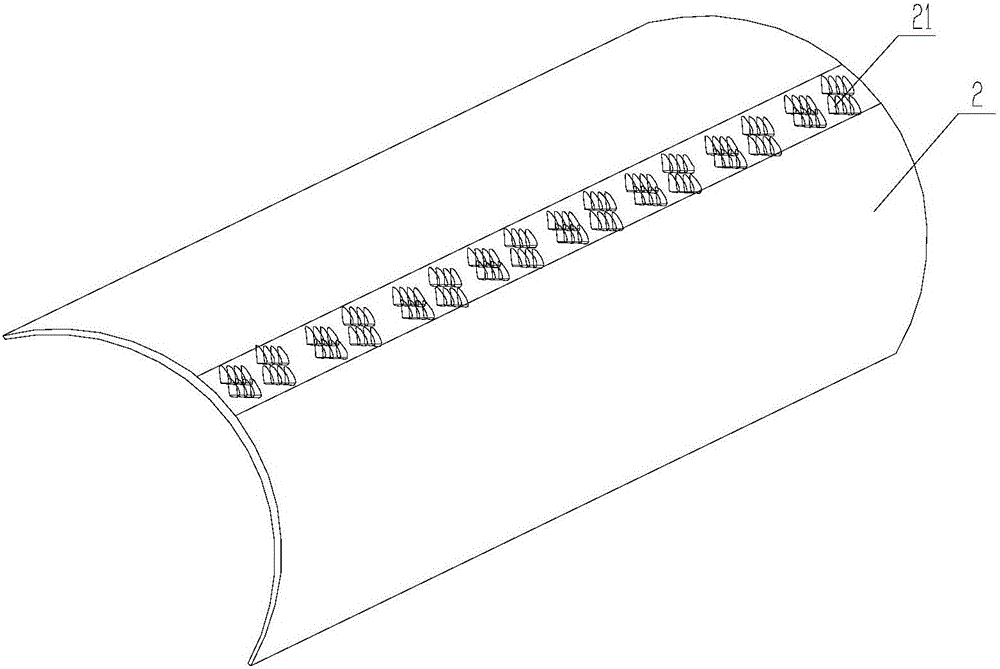

[0037] Such as Figure 1 to Figure 6 As shown, this embodiment provides a self-cleaning cylinder, including an outer cylinder 1, and an inner cylinder 2 sleeved in the outer cylinder 1 and rotatably connected with the outer cylinder 1, wherein the outer cylinder 1 and the inner cylinder 2 A cleaning device 3 is arranged therebetween, and during the relative rotation of the inner cylinder 2 and the outer cylinder 1 , the cleaning device 3 cleans the inner wall of the outer cylinder 1 and the outer wall of the inner cylinder 2 .

[0038] The above-mentioned self-cleaning cylinder is suitable for being installed on a washing machine, especially suitable for being installed on a drum washing machine. By setting the cleaning device 3 between the inner cylinder 2 and the outer cylinder 1, during the working process of the washing machine, the cleaning device 3 will clean the outer wall of the washing machine inner cylinder 2 and the inner wall of the outer cylinder 1, that is, as lo...

Embodiment approach 2

[0050] In this embodiment, another specific installation form of the cleaning device is provided. The cleaning devices 3 provided on the outer cylinder 1 and the cleaning devices 3 provided on the inner cylinder 2 are arranged alternately along the cylinder axis. Specifically as described below, the fixed portion 31 of the cleaning device 3 includes a plurality of fixed portion units arranged at intervals, and the wiping portion 32 includes a plurality of wiper units distributed at intervals, and the wiper units are arranged on the fixed portion in one-to-one correspondence. on the unit.

[0051] Both the outer cylinder 1 and the inner cylinder 2 are provided with a cleaning device 3, the fixed part unit is fixedly connected with the corresponding outer cylinder 1 or inner cylinder 2, and the fixed part unit on the outer cylinder 1 is connected to the fixed part on the inner cylinder 2 The units are arranged in a staggered manner.

[0052] That is, the fixed portion unit of t...

Embodiment approach 3

[0056] In this embodiment, another specific installation form of the cleaning device is provided. Both the outer cylinder 1 and the inner cylinder 2 are provided with groove structures, and the groove structures on the outer cylinder 1 and the inner cylinder 2 are both provided with The cleaning device 3, and the fixed part 31 of the cleaning device 3 is telescopically connected with the corresponding groove structure.

[0057] Concretely, a guide column 35 is arranged at both ends of the groove structure 34 respectively, and the two ends of the fixed part 31 are respectively slidably connected with the two guide columns 35, and a spring 36 is also sleeved on the guide column 35, and one end of the spring 36 is connected to the guide column 35. The fixing portion 31 is in contact with the other end of the groove structure 34 .

[0058] More specifically, the first cleaning device 11 is arranged on the outer cylinder 1 through the cooperation of the guide post 35, the spring 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com