Method for separating cyclopentane and neohexane by using extractive rectification technology

A technology of extractive distillation and extractive distillation column, which is applied in the field of separation of cyclopentane and neohexane by extractive distillation process, can solve the problems of poor separation effect and high energy consumption in the separation process, and achieve easy separation and good solubility , Facilitate the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

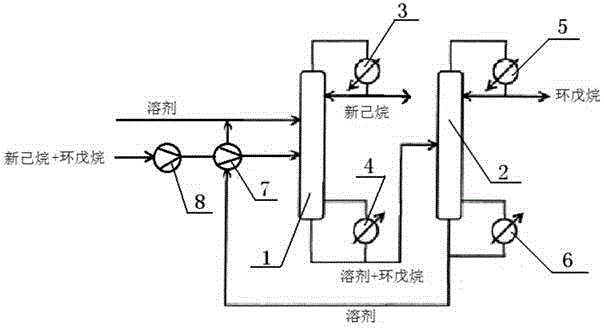

[0057] In the middle part of the extractive distillation tower 1, the cyclopentane / neohexane system is continuously fed in a saturated gas phase feeding mode; at the same time, at the 4th tray below the top of the extractive distillation tower 1, The solvent at 52°C was fed continuously. In the extractive distillation tower 1, neohexane is separated from cyclopentane under the action of solvent, and then neohexane (gas phase) is distilled from the top of the extractive distillation tower 1 and condensed to liquid through the first condenser 3. The mixture (liquid phase) of cyclopentane and solvent is distilled out from the bottom of the extractive distillation tower 1, and after being further heated by the first reboiler 4, it enters the solvent recovery tower 2. In the solvent recovery tower 2, cyclopentane is separated from the solvent, and then cyclopentane (gas phase) is distilled from the top of the solvent recovery tower 2, and condensed to the liquid phase by the second...

Embodiment 2

[0061] The operation steps of this embodiment and embodiment 1 are basically the same, the difference is:

[0062] 1) The feed temperature of the solvent is 53° C.; and the solvent is fed at the third tray below the top of the extractive distillation column 1 .

[0063] 2) The top pressures of the extractive distillation tower 1 and the solvent recovery tower 2 are both 110kPa.

[0064] 3) The mass ratio of the solvent to the cyclopentane / neohexane system is 5:1.

[0065] 4) The solvent used includes 7 parts by mass of a main solvent and 1 part by mass of a secondary solvent: the main solvent is NMF, and the secondary solvent is cyclopentanol.

[0066] The purity of neohexane and cyclopentane separated in this embodiment was measured, and the results showed that the purity of neohexane was as high as 99.47%, and the purity of cyclopentane was as high as 99.5%. It can be seen that using the method provided by the embodiment of the present invention to separate cyclopentane an...

Embodiment 3

[0068] The operation steps of this embodiment and embodiment 1 are basically the same, the difference is:

[0069] 1) The feed temperature of the solvent is 55° C.; and the solvent is fed at the third tray below the top of the extractive distillation column 1 .

[0070] 2) The top pressures of the extractive distillation tower 1 and the solvent recovery tower 2 are both 112kPa.

[0071] 3) The mass ratio of the solvent to the cyclopentane / neohexane system is 7:1.

[0072] 4) The solvent used includes 4 parts by mass of main solvent and 1 part by mass of secondary solvent: the main solvent is NMF, and the secondary solvent is ethylene glycol.

[0073] The purity of neohexane and cyclopentane separated in this embodiment was measured, and the results showed that the purity of neohexane was as high as 99.45%, and the purity of cyclopentane was as high as 99.43%. It can be seen that using the method provided by the embodiment of the present invention to separate cyclopentane and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com