Compound microbial-fermented organic fertilizer and preparation method therefor

A technology of compound microorganisms and organic fertilizers, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of poor disease resistance, weak fertilizer fertility, and poor sugarcane yield improvement effect, and achieves strong growth inhibition rate, High fertility and improvement of soil pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

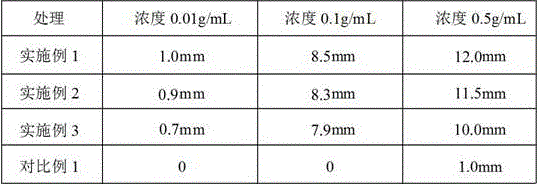

Examples

Embodiment 1

[0041] (1) Preparation of decomposed mixed bacteria: Inoculate the activated Bacillus subtilis and Bacillus thermophilic licheniformis into the culture medium of the Erlenmeyer flask respectively, the inoculation amount is 3-5% (V / V), and inoculate them after 12 hours of cultivation until fermentation Expand the tank culture medium until the number of viable bacteria reaches 10 8 cfu / mL to get Bacillus subtilis culture fluid and thermophilic Bacillus licheniformis culture fluid;

[0042] Among them, the medium components of Bacillus subtilis are based on mass percentage content: glucose 6%, yeast extract 1%, peptone 0.2%, CaCO 3 1%, the rest is water; culture temperature is 28-32℃;

[0043] The medium components of the thermophilic Bacillus licheniformis culture medium are calculated by mass percentage: 0.5% yeast extract, 0.5% peptone, 5% brown sugar, 0.1% Tween-80, 0.05% sodium chloride, 0.05% dihydrogen phosphate Potassium, 0.05% magnesium sulfate, 0.05% calcium carbona...

Embodiment 2

[0056] (1) Preparation of decomposed mixed bacteria: use the steps in the example (1) to obtain the Bacillus subtilis culture solution and the thermophilic Bacillus licheniformis culture solution; Mixed at 1.5:1 to obtain decomposed mixed bacteria;

[0057](2) Preparation of feces straw decomposed clinker: mix pig manure and wheat straw powder evenly at a mass ratio of 3:1 to obtain fermentation raw materials; add decomposed mixed bacteria with an inoculum amount of 8% (g / g) to the fermentation raw materials , adjust the moisture content to 50%, loosely place it in the fermentation tank, and ferment under the condition of 40-45 ° C. During the fermentation process, turn the pile once every 3 days, and ferment for 15 days until it reaches maturity, that is, the decomposed clinker;

[0058] (3) Preparation of culture solution for pathogen-inhibiting bacteria of sugarcane perennial dwarf disease: expand the activated Bacillus thuringiensis according to the method of step (3) in E...

Embodiment 3

[0063] (1) Preparation of decomposed mixed bacteria: use the steps in the example (1) to expand culture to obtain Bacillus subtilis culture fluid and thermophilic Bacillus licheniformis culture fluid; Mixed at 2.5:1 to obtain decomposed mixed bacteria;

[0064] (2) Preparation of feces straw decomposed clinker: mix pig manure and wheat straw powder evenly at a mass ratio of 2.5:1 to obtain fermentation raw materials; add decomposed mixed bacteria with an inoculum amount of 12% (g / g) to the fermentation raw materials , adjust the moisture content to 53%, loosely place it in the fermentation tank, and ferment it under the heat preservation condition of 50-55°C. During the fermentation process, turn the pile once every 3 days, and ferment for 11 days until it reaches maturity to obtain the decomposed clinker;

[0065] (3) Preparation of culture solution for pathogen-inhibiting bacteria of sugarcane perennial dwarf disease: expand the activated Bacillus thuringiensis according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com