Wastewater treatment process of iron-copper-sulfur polymetallic mine slurry detention reservoir

A wastewater treatment, multi-metal technology, applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sludge/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

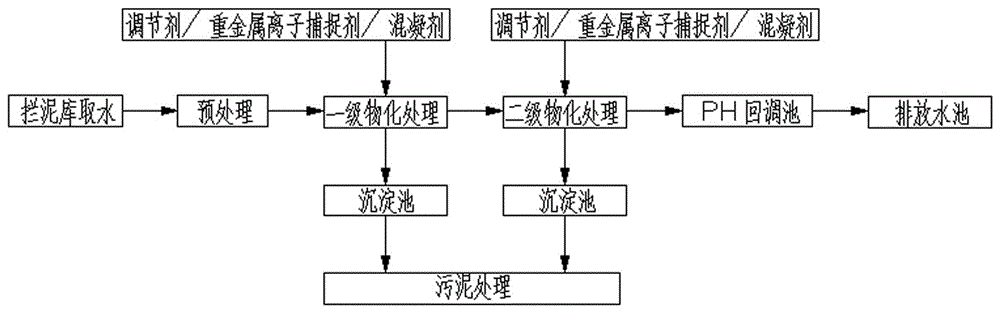

[0030] see figure 1 , a kind of iron-copper-sulfur polymetallic mine silt storage wastewater treatment process, its process steps are:

[0031] Step 1: Take water from the silt storage, adopt the siphon water intake method, make the waste water flow through multi-stage energy dissipation wells to slow down the flow rate, and enter the sedimentation tank through the sewage pipe;

[0032] The second step: pretreatment, the waste water from the mud storage tank enters the sedimentation tank to remove most of the sundries and sand particles, and then enters the buffer tank for homogenization and removal of part of the suspended solids. At the same time, oxidants are added to the buffer tank to remove the reduction of ferrous iron Reactive substances, or use air instead of oxidants to pass into the buffer pool to oxidize reducing substances;

[0033] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com