A kind of concrete curing method

A technology for concrete and concrete surface, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of concrete surface hazards, difficult façade coverage, waste of water, etc., to reduce concrete curing water, improve concrete quality, and improve urban environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

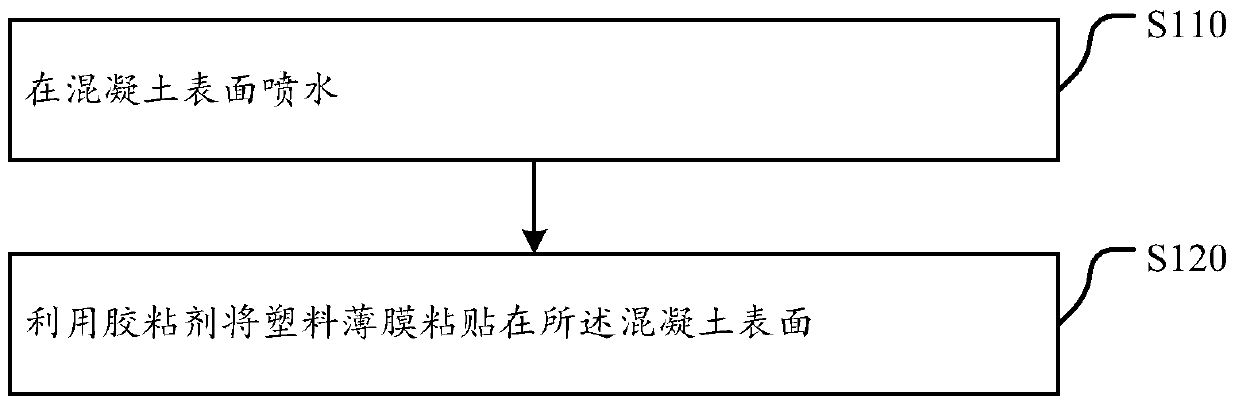

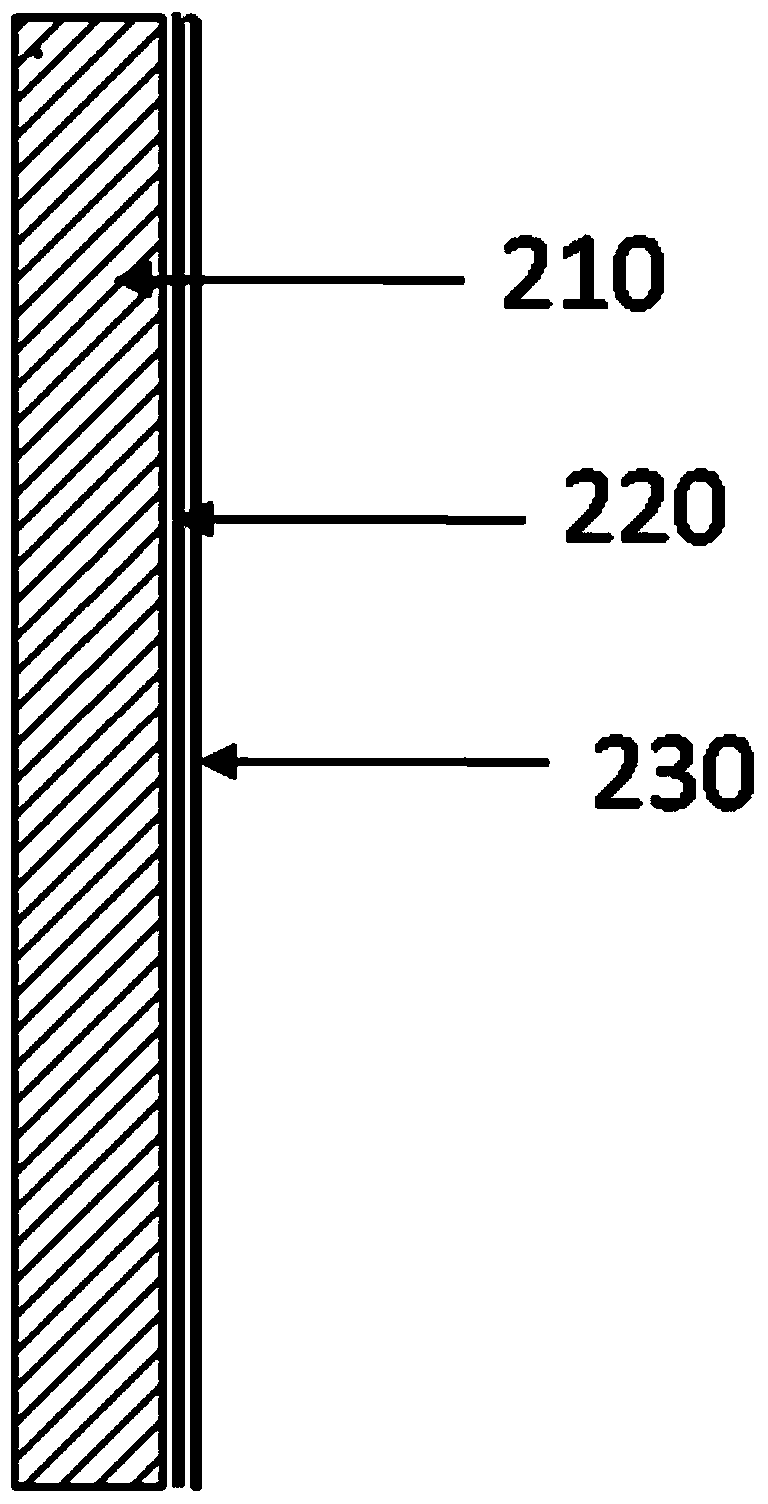

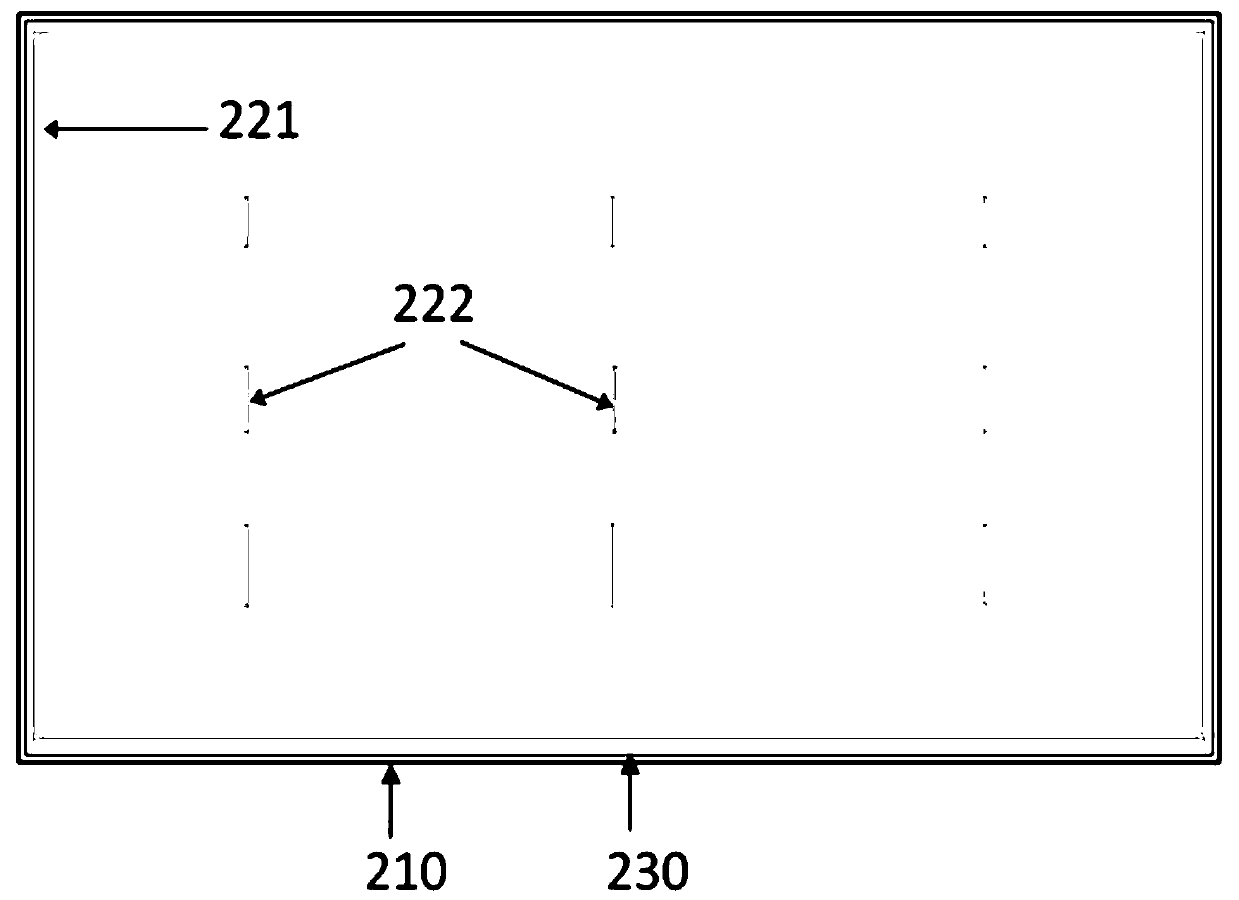

Method used

Image

Examples

Embodiment 1

[0054] Colloidal solution material preparation stage:

[0055] Take 2-10 mass parts of polyvinyl ester hydrolyzed polymers, preferably, include one or more of polyvinyl acetate, polyvinyl propionate and polyvinyl butyrate hydrolyzed polymers, heat-soluble in 100 mass parts In water, for example, 2-10 kg of polyvinyl ester hydrolyzed polymer can be taken and dissolved in 100 kg of water at 90-100 ° C, and after 0.5-3 hours, the polyvinyl ester hydrolyzed polymer is completely dissolved to form a polymer solution.

[0056]The polymer solution is statically cooled to 30-50°C, and the activator is added according to the following mass ratio, polymer solution: activator=100:0.25-3.75, for example, take 100kg polymer solution and 0.25-3.75kg activator Mix and stir evenly, stop the chemical reaction for 0.5-2 hours, form a clear and transparent colloidal solution material, cool to room temperature for use, wherein the activator includes one or more of the following substances: metha...

Embodiment 2

[0060] Colloidal solution material preparation stage:

[0061] Take 2-10 mass parts of polyvinyl ester hydrolyzed polymers, preferably, include one or more of polyvinyl acetate, polyvinyl propionate and polyvinyl butyrate hydrolyzed polymers, heat-soluble in 100 mass parts In water, for example, 2-10 kg of polyvinyl ester hydrolyzed polymer can be taken and dissolved in 100 kg of water at 90-100 ° C, and after 0.5-3 hours, the polyvinyl ester hydrolyzed polymer is completely dissolved to form a polymer solution.

[0062] Stop cooling the polymer solution to 30-50°C, add triethanolamine and activator according to the following mass ratio, polymer solution: triethanolamine: activator = 100:0.05-0.26:0.25-3.75, for example, take 100kg Polymer solution, 0.05-0.26kg triethanolamine and 0.25-3.75kg activator are mixed and stirred evenly, and the chemical reaction is stopped for 0.5-2 hours to form a clear and transparent colloidal solution material, cooled to room temperature for u...

Embodiment 3

[0066] Colloidal solution material preparation stage:

[0067] Take 2-10 mass parts of polyvinyl ester hydrolyzed polymers, preferably, include one or more of polyvinyl acetate, polyvinyl propionate and polyvinyl butyrate hydrolyzed polymers, heat-soluble in 100 mass parts In water, for example, 2-10 kg of polyvinyl ester hydrolyzed polymer can be taken and dissolved in 100 kg of water at 90-100 ° C, and after 0.5-3 hours, the polyvinyl ester hydrolyzed polymer is completely dissolved to form a polymer solution.

[0068] The polymer solution is statically cooled to 30-50°C, and glycerol and activator are added according to the following mass ratio, polymer solution: glycerol: activator=100:0.05-0.8:0.25-3.75, for example, take 100kg of polymer solution, 0.05-0.8kg of glycerol and 0.25-3.75kg of activator are mixed and stirred evenly, and the chemical reaction is stopped for 0.5-2 hours to form a clear and transparent colloidal solution material, which is cooled to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com