Energy saving assembly used in rattan weaving

A rattan and component technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of low yield, time-consuming and labor-intensive, etc., and achieve the effects of strong practicability, simple overall structure design, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

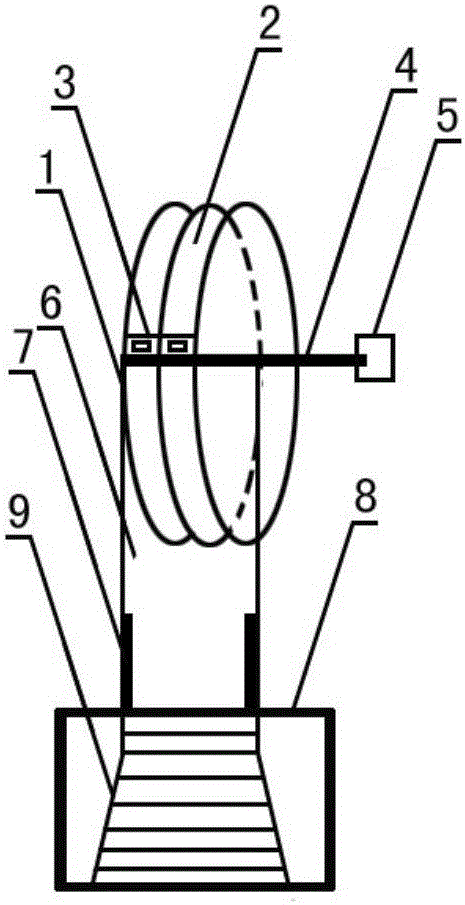

[0012] Embodiment: as shown in the accompanying drawing. The labor-saving component in the production of rattan weaving includes a frame body (1), the frame body (1) is in an upright design as a whole, and the upper part is provided with a disc structure including two groove-shaped disc devices (2), a positioning module ( 3), the rotating shaft device (4), the clamping device (5), the vertical support rod device (6) is arranged in the middle, the lifting device (7) is arranged inside the rod body, and the base cover device (8) is arranged at the bottom of the frame body (1) , When in use, according to the weaving requirements, stretching, positioning and other operations are performed on the rattan, saving time and effort.

[0013] A labor-saving component in rattan weaving, the bottom of the frame body (1) is provided with a pedal device (9) connected to the rotating shaft device (4) for adjusting the running speed.

[0014] As a labor-saving component in the production of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com