Pneumatic artificial muscle with self-sensing and driving functions

A pneumatic artificial muscle, self-sensing technology, applied in the direction of manufacturing tools, manipulators, program-controlled manipulators, etc., can solve problems such as high cost, complex structure, difficult calculation, etc., and achieve the effect of improving the shrinkage and stiffness adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

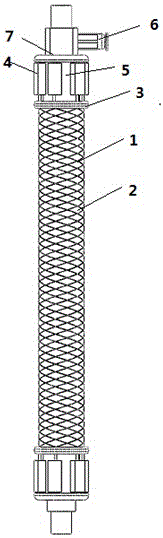

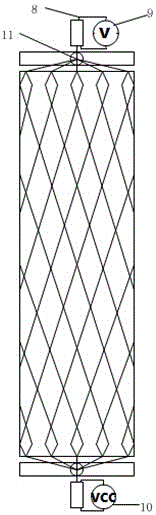

[0014] Such as figure 1 , figure 2 As shown, this embodiment includes a fiber filament 1, an elastic hose 2, a wire-collecting clamp 3, a piezoelectric body 4, a cylindrical sleeve 5, a trachea joint 6, a clamp 7, an electrode 8, a driving circuit 9, and a sensing circuit 10 , thread collecting hole 11. In this example, the piezoelectric body 4 close to the intake pipe interface 6 is used as the sensing part, and the piezoelectric body 4 at the other end of the pneumatic muscle is used as the driving part; the elastic hoses 2 are all rubber elastic hoses, which expand after inflation; The filament 1 is wound on the outer surface of the elastic hose 2 at a fixed braiding angle to form a braided net, wherein the filaments 1 at both ends of the elastic hose are drawn out separately, and the drawn filaments are divided into 6 equal parts. In ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com