A Simple CNC Servo Screw Grinding Device

A screw and simple technology, applied in the field of thread grinding devices, can solve the problems of high price, high labor cost and high processing cost of CNC thread grinder, and achieve the effect of simple structure, improved efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

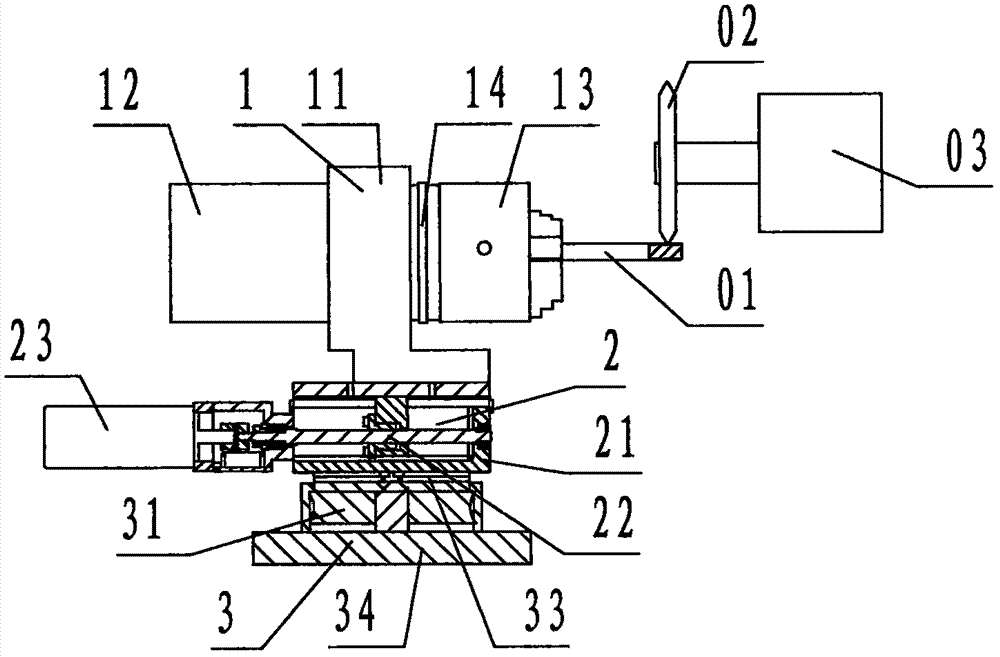

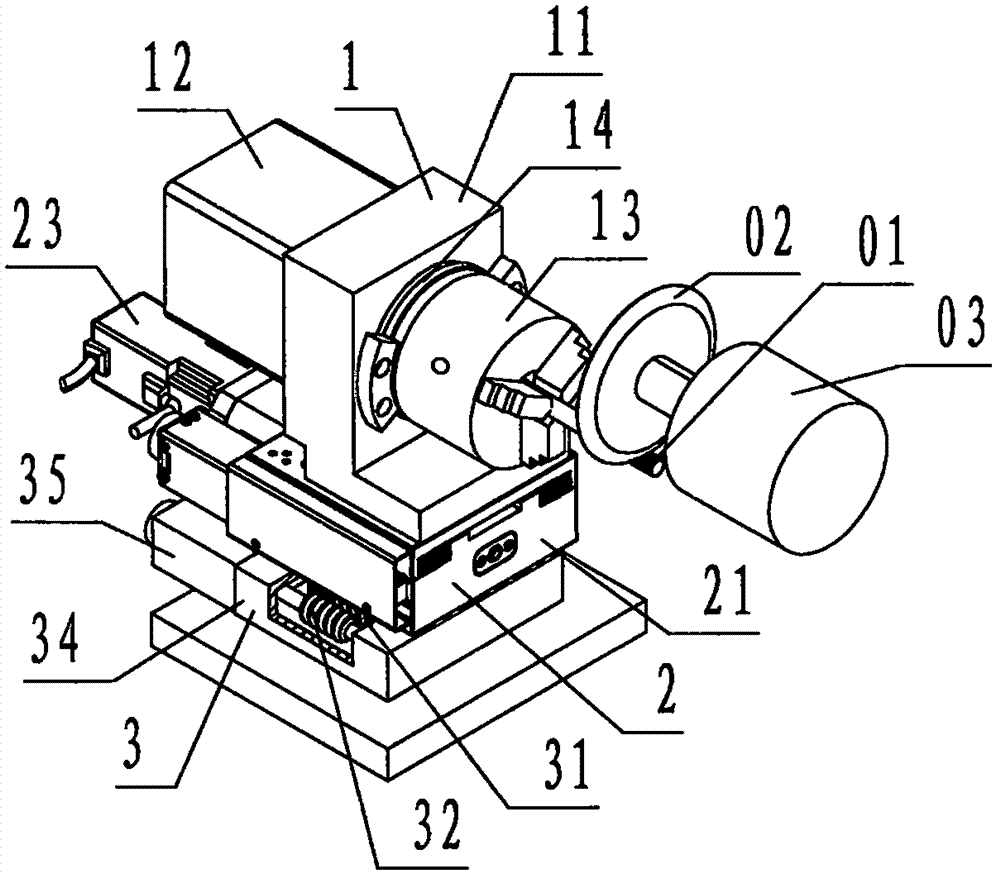

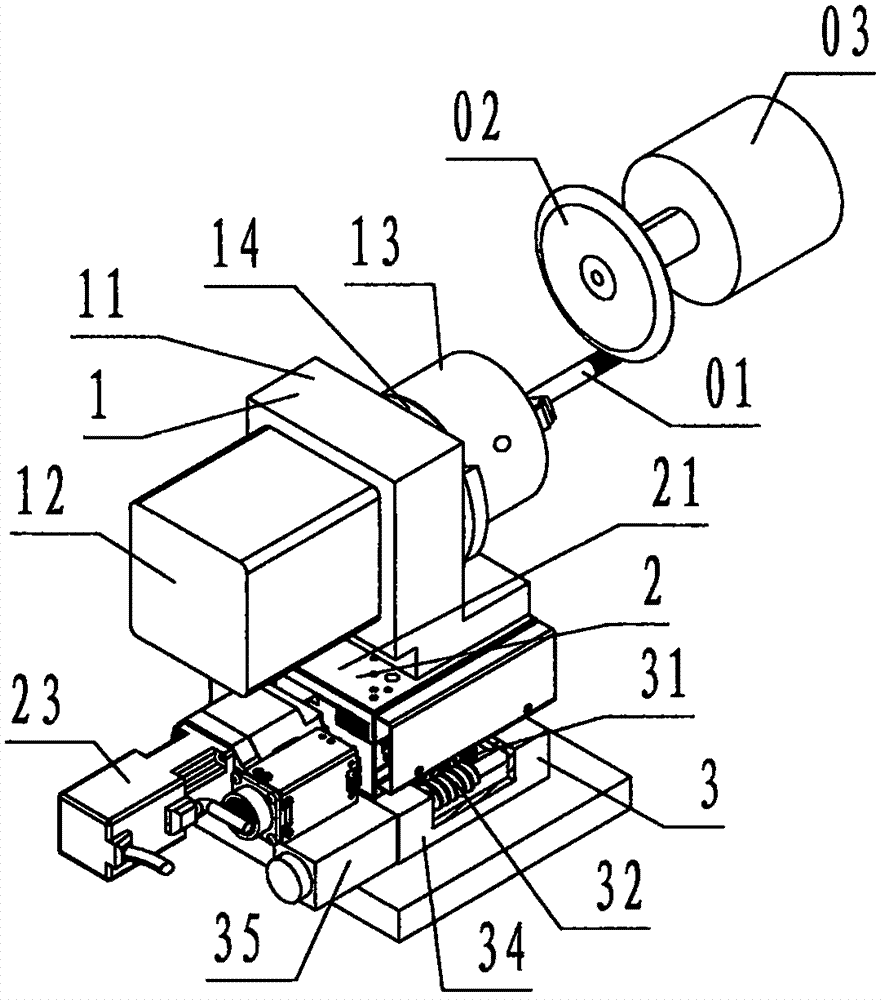

[0023] refer to Figure 1 ~ Figure 3 , a simple numerically controlled servo screw grinding device of the present invention, including a rotating mechanism 1, a reciprocating mechanism 2, and a plane indexing table 3, wherein: the rotating mechanism 1 is composed of a base A 11, a servo motor 12 and a clamp 13 , the A base 11 is provided with an upwardly protruding wallboard on the left, a base protruding upwardly to the right below, and an L-shaped block steel member. The center of the wallboard of the A base 11 is provided with left and right A connecting shaft 14 that passes through the wallboard and is used to transmit rotational motion; the clamp 13 is a three-jaw self-centering chuck; the A servo motor 12 is fixed on the left side of the A base 11, and the clamp 13 is located on the A base On the right side of the seat 11, the output end of the A servo motor 12 is connected to the fixture 13 through the connecting shaft 14;

[0024] The reciprocating mechanism 2 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com