A foam board automatic spray coating equipment

An automatic spraying and foam board technology, applied in the spray booth, spraying device, etc., can solve the problems of inconvenience, lower production efficiency, easy deviation from the track, etc., and achieve the effect of convenient movement and convenient spray coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

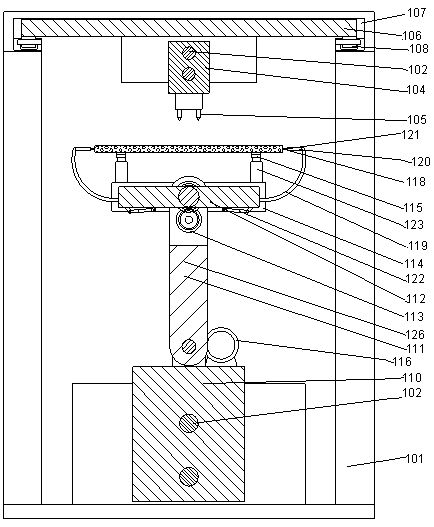

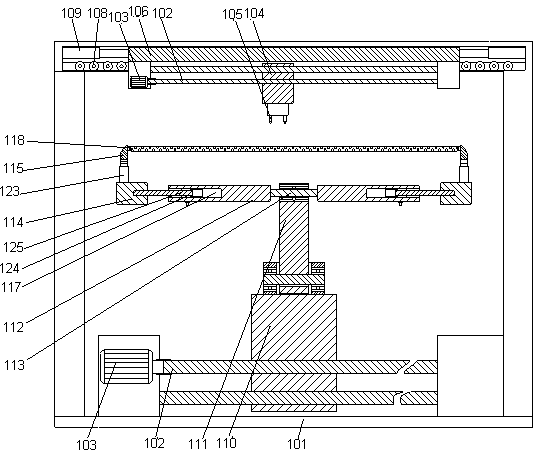

[0028] Such as figure 1 , 2 As shown, a foam board automatic spraying and coating equipment includes a frame 101 and a beam 106 arranged above the frame, a screw base is provided on the beam, and a screw base is arranged on the base of the screw A lead screw 102 is provided, a nozzle base 104 is arranged on the lead screw, and a nozzle 105 is arranged below the nozzle base;

[0029] A clamping device is provided on the frame below the spray head, and the clamping device includes a support 110 and a support rod 111 arranged on the support, and the support rod is far away from the One end of the support is provided with a positioning plate 112, an extension plate 114 is provided at the end of the positioning plate away from the support rod, and two fixing frames 115 are provided on the upper end surface of the extension plate;

[0030] The support rod is connected to the support by rotating a rotating shaft connected to the support, and a support rod driving motor 116 for driv...

Embodiment 2

[0039] In this embodiment, on the basis of Embodiment 1, in order to facilitate the adjustment of the height of the fixed frame, in this embodiment, preferably, two fixed frame hydraulic cylinders 123 are arranged on the upper end surface of the extension plate. The base of the hydraulic cylinder of the fixed frame is fixedly connected to the extension plate, and the expansion rod of the hydraulic cylinder of the fixed frame is fixedly connected to the end of the fixed frame. Start the hydraulic cylinder of the fixed frame so that it is located on both sides of the foam board, so that it is convenient to adjust the position of the extension board, so that it can be applied to the processing of foam boards of different widths.

[0040] In order to make the fixing frame adhere to the side wall of the foam board more firmly, in this embodiment, preferably, a suction cup 118 is provided on the upper end surface of the fixing frame away from the hydraulic cylinder of the fixing fram...

Embodiment 3

[0042] In this embodiment, on the basis of Embodiment 1 or 2, in order to prevent the extension plate hydraulic cylinder from being subjected to radial force and avoid its damage, in this embodiment, preferably, a There is a positioning hole 124, the extension plate hydraulic cylinder is located inside the positioning hole, a chute is arranged inside the positioning hole, a slider 125 is arranged inside the chute, and the slider 125 is arranged inside the chute. One end is fixedly connected to the expansion rod of the extension plate hydraulic cylinder, and the other end of the slider is fixedly connected to the end surface of the extension plate opposite to the positioning plate. Through the cooperation between the slider and the chute structure, the slider can only move along the length direction of the chute, so that when the slider moves along a constant direction, the hydraulic cylinder of the extension plate is only subjected to the force along its axial direction, avoidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com