Polyacrylonitrile/polyimide-based composite carbon airgel electrode material and preparation method

A polyimide-based and polyacrylonitrile technology, which is applied in the field of polyacrylonitrile nanofiber/polyimide-based composite carbon airgel electrode materials and its preparation, can solve the problems of inhibiting electrochemical activity, improving, and limiting ratio Surface area and other issues, to achieve the effect of improving mechanical compression performance, increasing specific surface area, and good compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

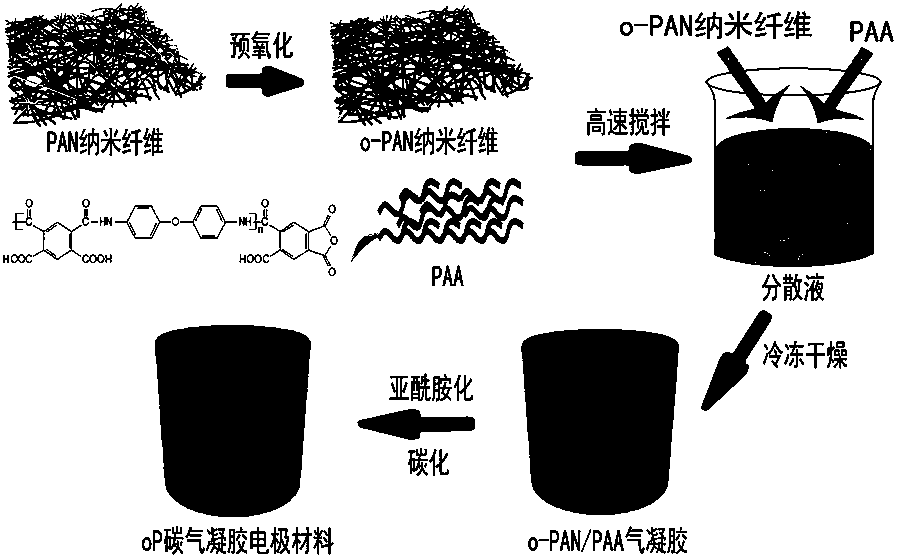

Embodiment 1

[0046] Stir and dissolve 3 g of polyacrylonitrile (PAN) powder in 30 mL of DMF to obtain polyacrylonitrile spinning solution, which is spun into a nanofiber membrane by electrospinning technology. The specific parameters are: the diameter of the spinning container is the diameter of the pinhole A 5 mL plastic syringe of 0.5 mm was used, the voltage was 18 kV, the flow rate was 0.2 mm / min, the receiving distance was 15 cm, and the spinning time was 1 h. Then the polyacrylonitrile precursor was pre-oxidized to obtain the pre-oxidized polyacrylonitrile (o-PAN) nanofiber membrane. The specific parameters were: the heating rate was 2 °C / min, and the platform temperature was raised to 250 °C and kept for 2 h. 1 g of the above-mentioned o-PAN nanofibers was weighed and dispersed in 50 mL of deionized water after high-speed stirring at 18000 r / min for 30 min to obtain a suspension (1). At the same time, 2 g of water-soluble polyamic acid was dissolved in another 50 mL of deionized wat...

Embodiment 2

[0050] Stir and dissolve 3 g of polyacrylonitrile (PAN) powder in 30 mL of DMF to obtain polyacrylonitrile spinning solution, which is spun into a nanofiber membrane by electrospinning technology. The specific parameters are: the diameter of the spinning container is the diameter of the pinhole A 5 mL plastic syringe of 0.5 mm was used, the voltage was 18 kV, the flow rate was 0.2 mm / min, the receiving distance was 15 cm, and the spinning time was 1 h. Then the polyacrylonitrile precursor was pre-oxidized to obtain the pre-oxidized polyacrylonitrile (o-PAN) nanofiber membrane. The specific parameters were: the heating rate was 2 °C / min, and the platform temperature was raised to 250 °C and kept for 2 h. Weigh 2 g of the above-mentioned o-PAN nanofibers and disperse them in 50 mL of deionized water after high-speed stirring at 18000 r / min for 30 min to obtain a suspension (1). At the same time, 1 g of water-soluble polyamic acid was dissolved in another 50 mL of deionized water...

Embodiment 3

[0054] Stir and dissolve 3 g of polyacrylonitrile (PAN) powder in 30 mL of DMF to obtain polyacrylonitrile spinning solution, which is spun into a nanofiber membrane by electrospinning technology. The specific parameters are: the diameter of the spinning container is the diameter of the pinhole A 5 mL plastic syringe of 0.5 mm was used, the voltage was 18 kV, the flow rate was 0.2 mm / min, the receiving distance was 15 cm, and the spinning time was 1 h. Then the polyacrylonitrile precursor was pre-oxidized to obtain the pre-oxidized polyacrylonitrile (o-PAN) nanofiber membrane. The specific parameters were: the heating rate was 2 °C / min, and the platform temperature was raised to 250 °C and kept for 2 h. Weigh 3 g of the above-mentioned o-PAN nanofibers, stir them at 18000 r / min for 30 min, disperse them in 50 mL of deionized water, pour them into a mold with a fixed shape, and freeze-dry them for 48 h to obtain a single-component polypropylene Nitrile nanofiber airgel, denoted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com