A device for the experiment of spraying and wall-impacting combustion in constant-volume projectiles

A technology of internal spraying and constant volume bombs, which is used in measuring devices, internal combustion engine testing, and engine testing. It can solve problems such as lack of satisfaction, and achieve the effects of small size, flexible operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings, but the protection scope of the present invention is not limited thereto.

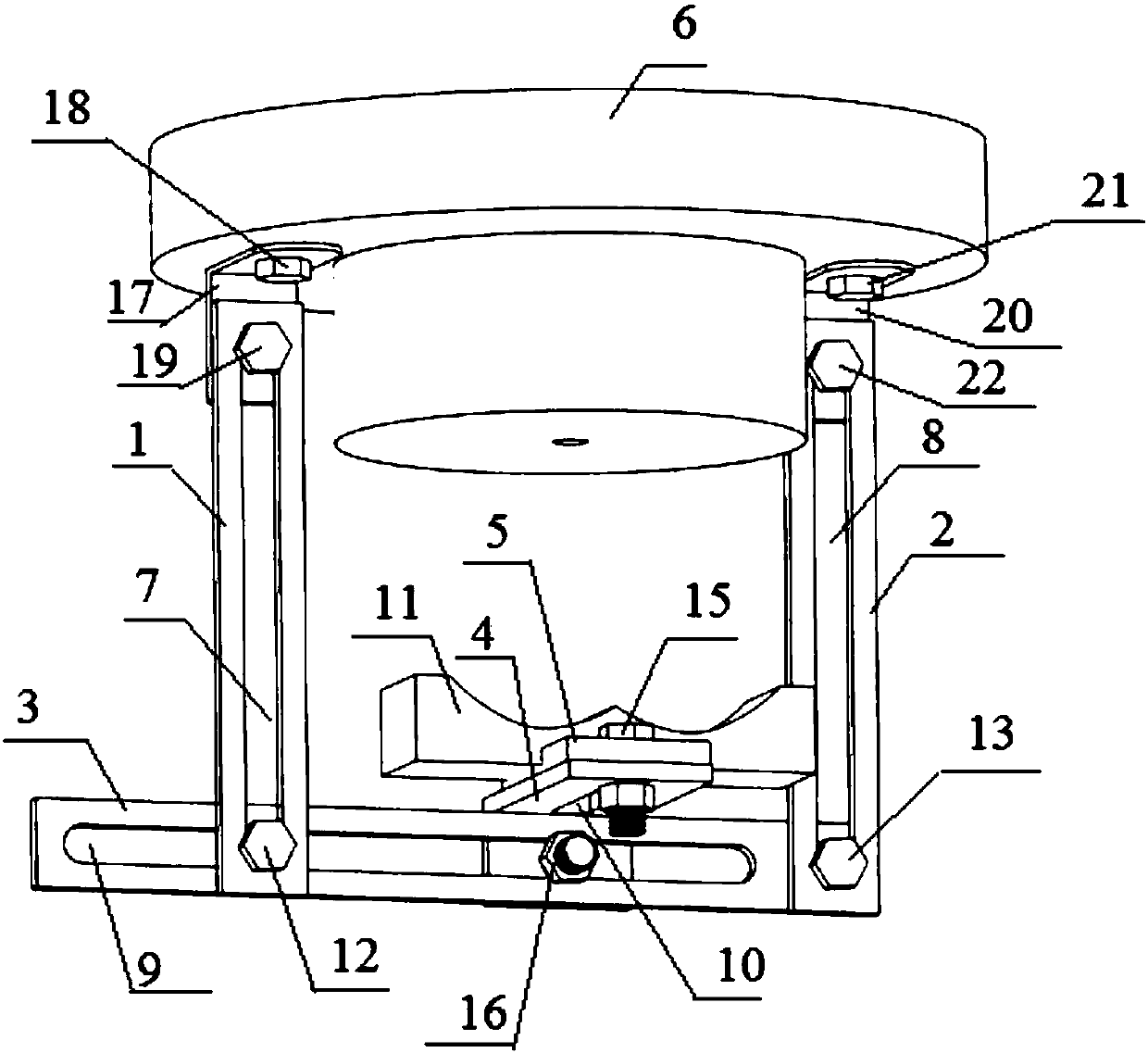

[0023] The device of the invention is installed in a bomb with constant volume, and can be used in a spray collision wall combustion experiment. figure 1 Shown is an embodiment of the experimental device for spraying wall impingement combustion in constant volume bombs, which includes a nozzle base 6 , a combustion chamber model bracket and a combustion chamber model 11 .

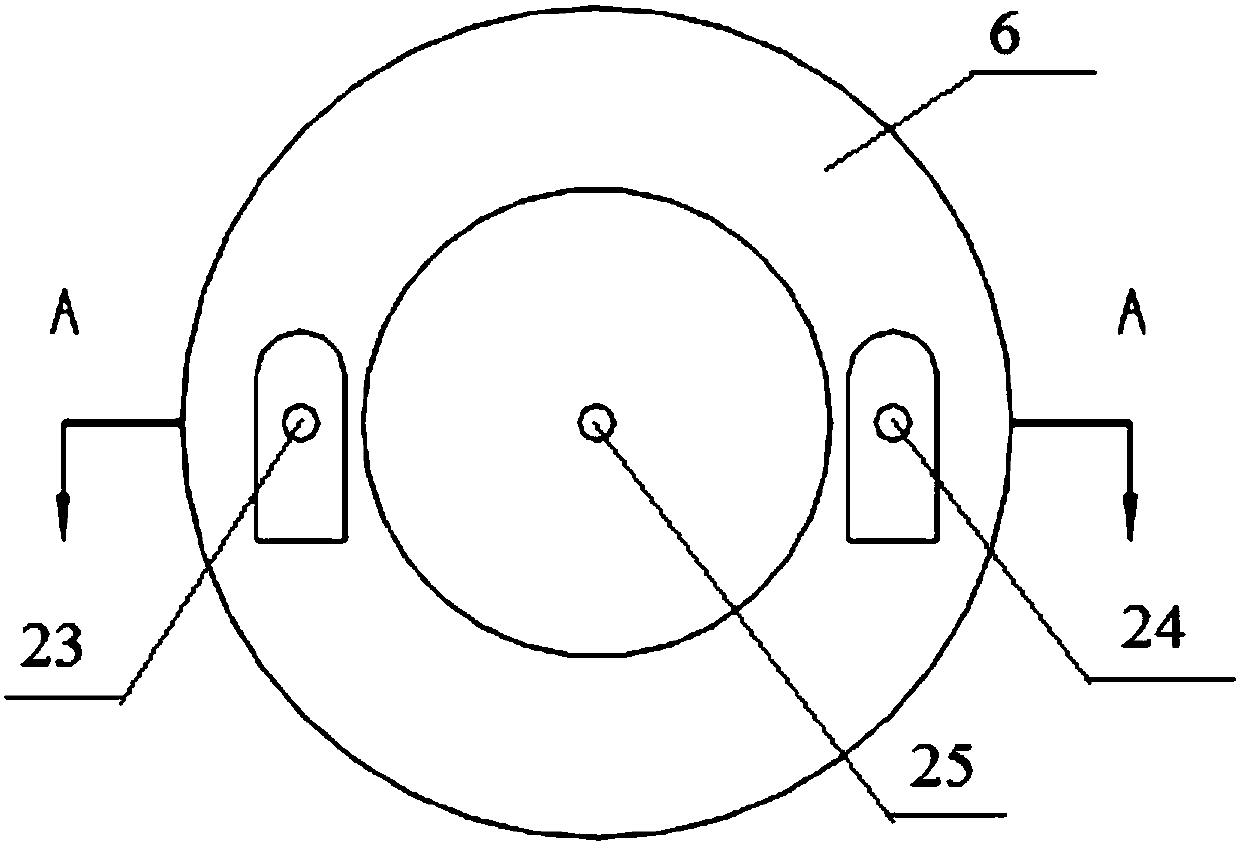

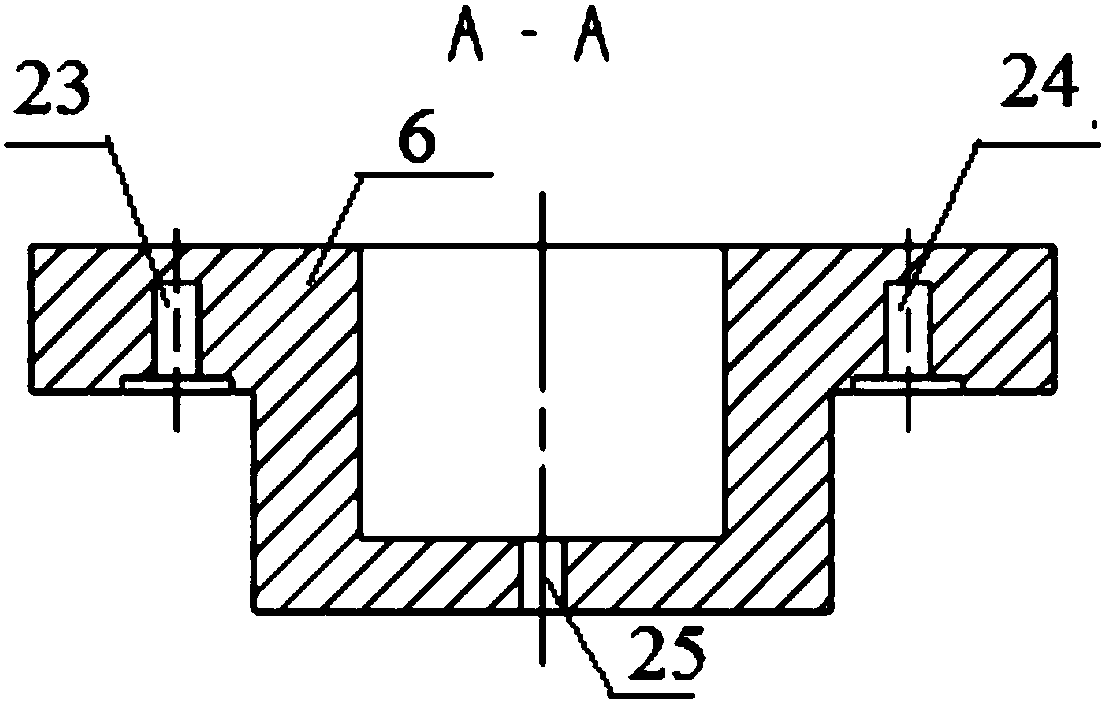

[0024] figure 2 and image 3 As shown, the nozzle base 6 is a circular truncated structure, the bottom has a nozzle hole 25, the nozzle hole 25 is used for the installation of the nozzle, and the periphery of the bottom is also provided with a first threaded hole 23 and a second threaded hole 24. The first threaded hole 23 and the second threaded hole 24 are symmetrical to each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com