Cylinder head assembly of motorcycle engine

A technology of engine cylinders and cylinder heads, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of increasing the overall size of the engine, difficult installation of camshafts, and unfavorable installation layout, and achieves good cooling effect and good heat dissipation. Effects, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

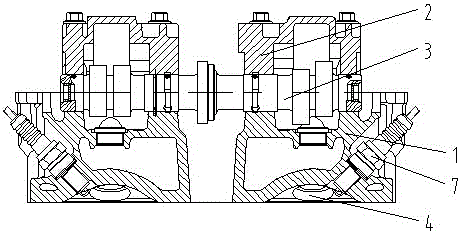

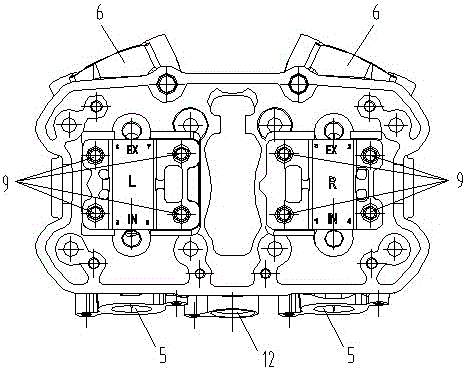

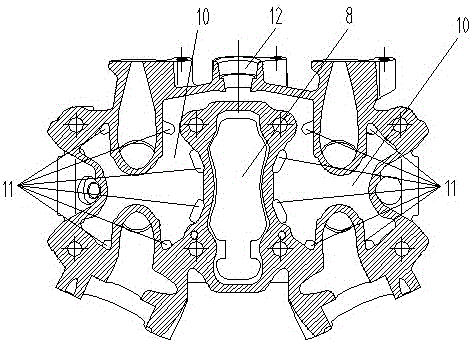

[0014] see Figure 1-Figure 3 , as can be seen from the figure, the motorcycle engine cylinder head assembly of the present invention is a double-cylinder engine cylinder head, including a cylinder head body 1, a rocker arm bracket 2 and a camshaft 3, and left and right arcs are arranged on the lower surface of the cylinder head body 1. Shaped pits to form two combustion chambers 4, and the cylinder head body 1 is provided with an intake port 5, an exhaust port 6 and a spark plug 7 corresponding to the two combustion chambers one by one. In the middle of the cylinder head body 1 between the two combustion chambers, there is a chain cavity 8 through which the upper end passes. In order to reduce casting difficulty, the cylinder head body 1 and the rocker arm bracket 2 are respectively casted, and then the rocker arm bracket 2 is fixedly installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com