PDC (Polycrystalline diamond compact)-impregnated segment hybrid self-adaptive drill bit

An impregnated block and self-adaptive technology, applied to drill bits, drilling equipment, earthwork drilling and production, etc., can solve problems such as delamination, PDC bit cutter fracture, and poor formation adaptability, so as to reduce impact damage, improve work efficiency and cost, and the effect of maintaining high-efficiency rock-crushing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

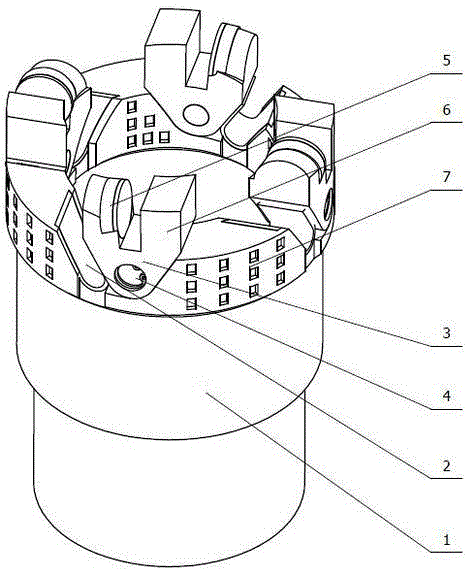

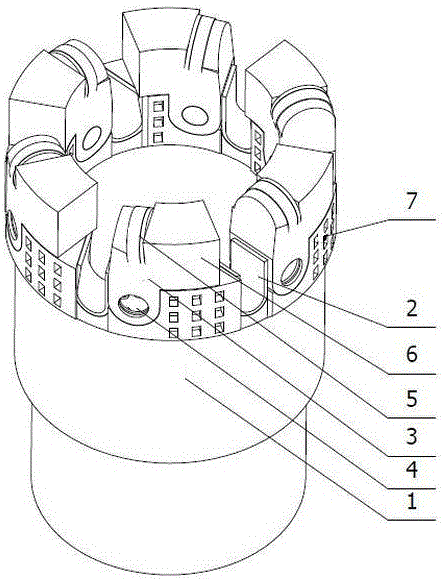

[0017] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is composed of a steel body 1, several adaptive elements 2 and several PDC tooth-impregnated block hybrid cutting blades 3, and the PDC tooth-impregnated block hybrid cutting blade 3 is fixedly set by a pin shaft 4 On the steel body 1, several adaptive elements 2 are respectively fixedly arranged between the steel body 1 and the PDC tooth-impregnated block hybrid cutting blade 3;

[0018] The PDC tooth-impregnated insert hybrid cutting blade 3 is composed of several PDC teeth 5 and several impregnated inserts 6, and the several PDC teeth 5 are respectively arranged on several impregnated inserts 6;

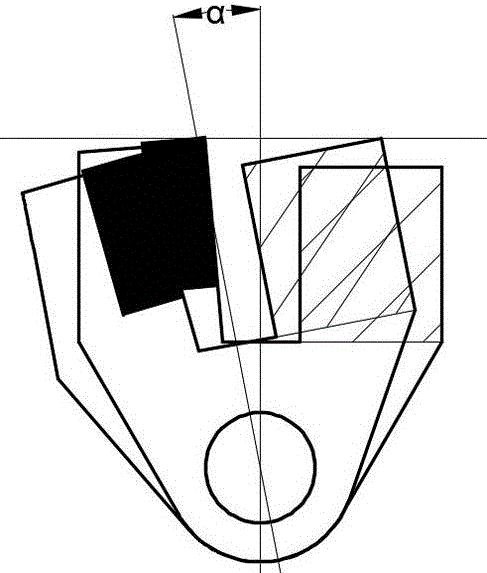

[0019] The initial working angle a of the PDC tooth 5 on the PDC tooth-impregnated block hybrid cutting blade 3 is 0-10°;

[0020] The height of the impregnated block 6 is lower than the upper working layer of the PDC tooth 5 .

[0021] Working principle and process of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com